.png)

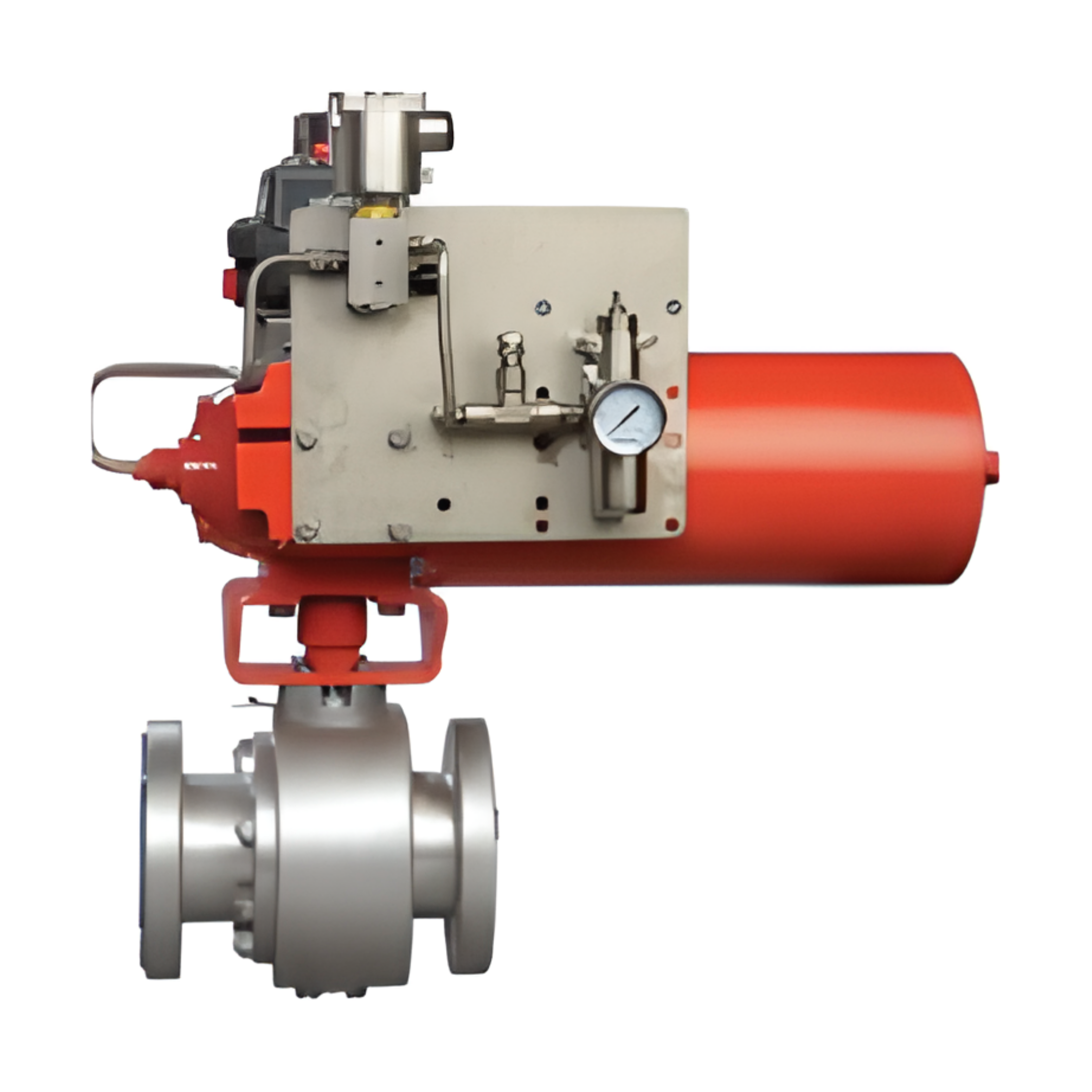

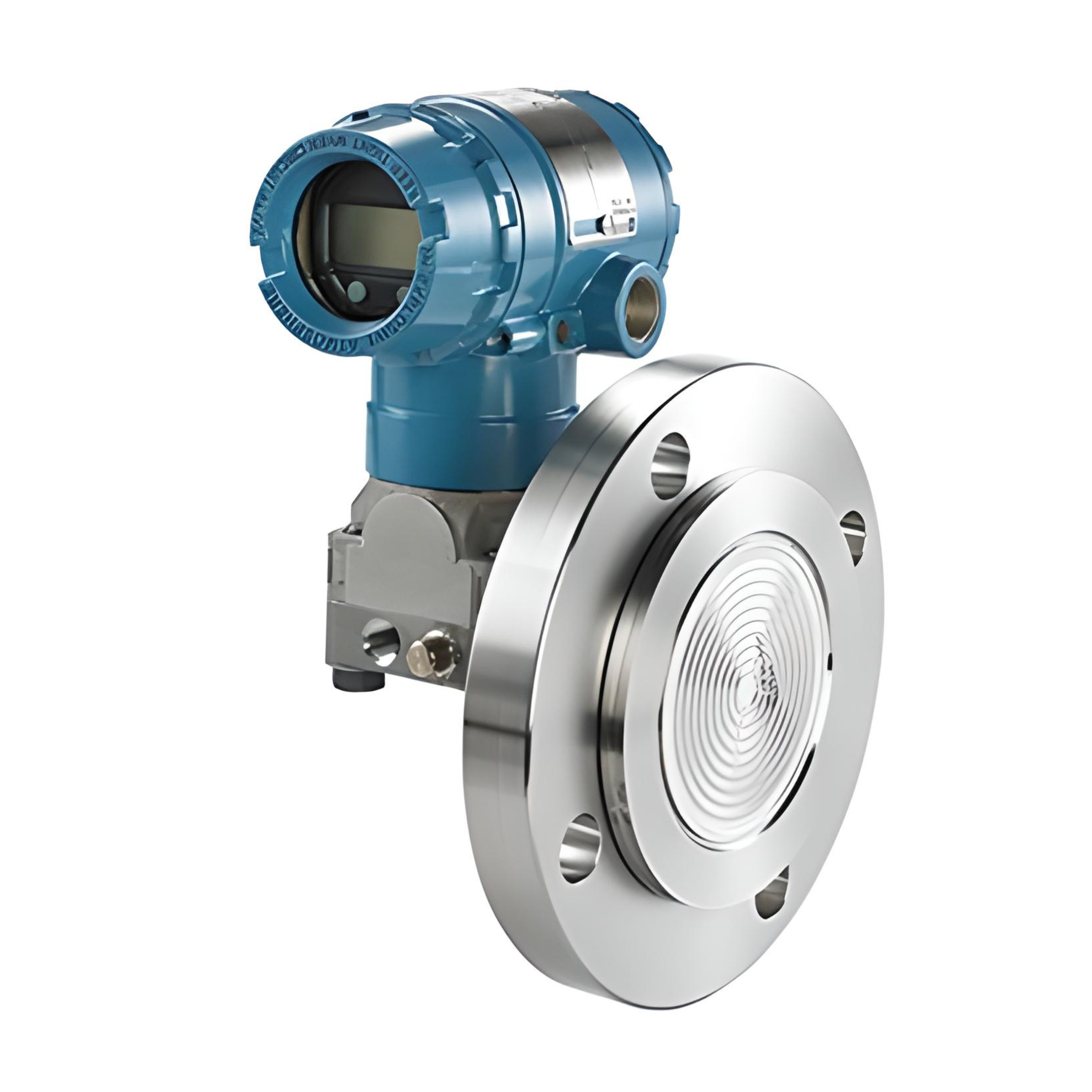

Calibrate Instrument Control Valve, Transmitter, Switch, and Indicator/gauge units.

- Control Valve Calibration aims to ensure the percentage of valve opening and closing is by the desired results (according to the datasheet). If in the process later the system/DCS orders to open the valve 25%, then the device must open 25% and up to 100%. We will recalibrate if the DCS wants 25% open, but the device is <25%.

- Transmitter calibration aims to ensure that the valve opening and closing percentage matches the desired results (according to the datasheet). If in the process later the system/DCS orders to open the valve 25%, then the device must open 25%, and so on, up to 100%. If the DCS wants 25% open, but the device is <25%, then we will recalibrate

- Switch calibration aims to determine the requested site point in the sense that if a flow process line is over range, the pressure switch device will order it to close the valve. (site point at 15% switch, the control valve or other unit valve above 15% device will close, on indication from the controller)

- The Indicator Gauge aims to measure the pressure in the flow lane. Therefore calibration is needed according to the range requested by the datasheet (if the flow lane pressure is 10 Psi, then the Gauge must show 10 Psi or less than 10 Psi with an accuracy of less than 0.5%.

_1681194562.jpg)