.png)

Air dryer is a tool that serves to remove the water content in compressed air (compressed air). This system is usually an integral part of the process with the compressor. The compressed air from the compressor will partly enter the storage tank and partly be dried using an air dryer.

The following types of dryers and their functions:

Refrigerated Dryers

Refrigerated air dryer is the most common type of compressed air dryer and can be cooled by water or air. This air dryer uses a cooling circuit and heat exchanger to cool the compressed air, cooling it to a level that condenses the moisture to be removed, and then reheat the air to prevent wet pipe downstream. Refrigerated air dryers can have a pressure dew point (PDP) as low as +37.4 ° F / + 3 °

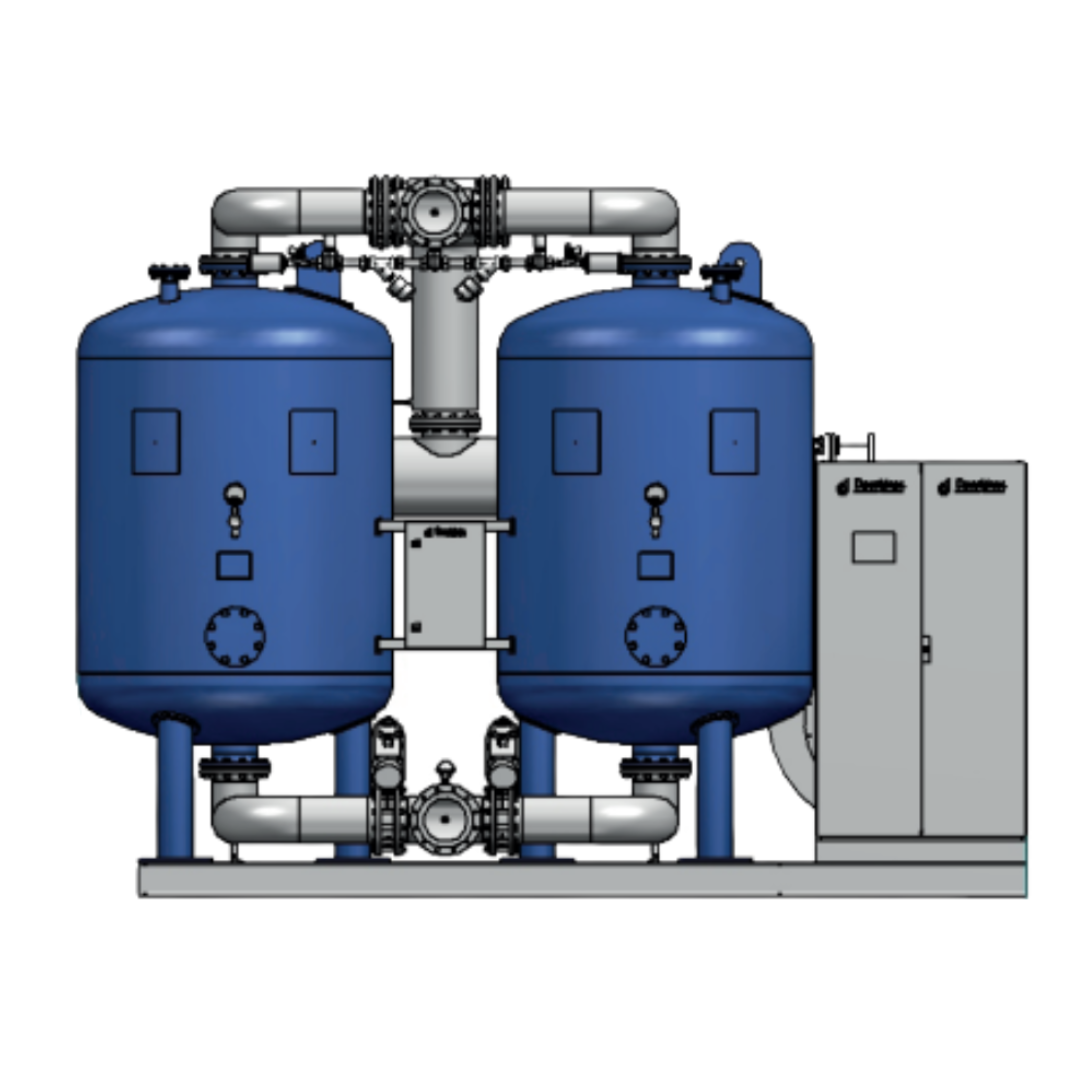

Desiccant Dryers

Desiccant air dryer works by relying on 2 tubes that work together but with different functions. As one tube dries the compressed air, the other regenerates. Dessicant air dryer can reach the lowest dew point -40 ° F / -40 ° C dan -100 ° F / -70 ° C. The use of porous dryers absorbs moisture by collecting it in numerous pores, allowing large amounts of water to be retained by a relatively small amount of desiccant. The types of desiccants used include silica gel, activated alumina, and molecular sieves.

Membrane Dryers

The membrane air dryer consists of a cylinder that holds thousands of hollow polymer fibers with an inner layer. When filtered wet compressed air enters the cylinder, the membrane lining allows moisture to permeate the membrane walls and collect between the fibers, while the dry air continues through the fibers in the cylinder with almost the same pressure as the incoming wet air.