.jpg)

Mining is a large industry that uses a variety of techniques and equipment for its processes. Extracting valuable resources from the ground requires extensive surface and underground operations to ensure maximum return and success.

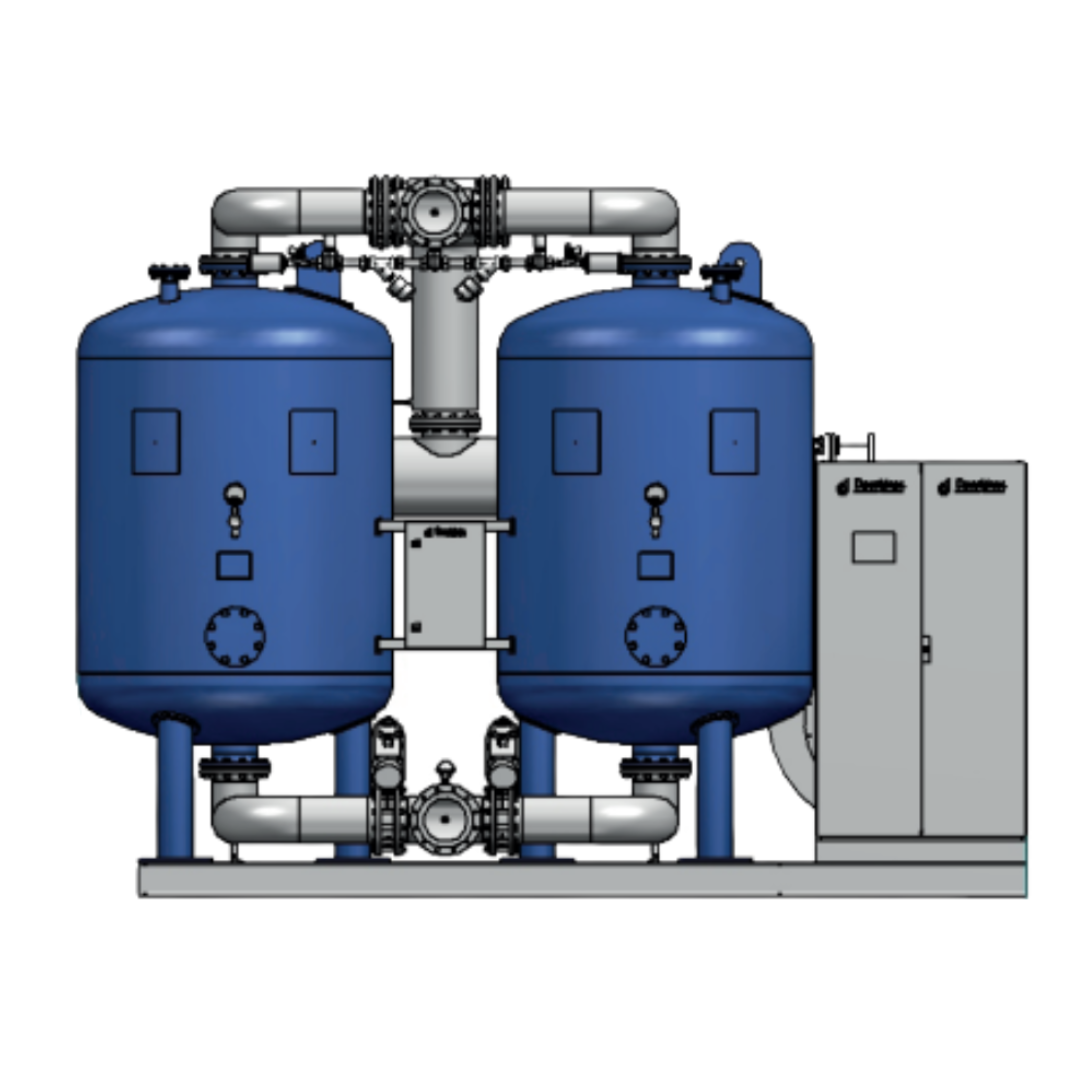

Mines can be miles long. Mining requires deep underground tunnels to extract minerals and resources from deep within the earth without losing efficiency or compromising safety. Working in the mining industry has many dangers, so using reliable, high-performance equipment is essential. Air compressors are used in mining as a power source for ventilation systems, material conveyors, pneumatic tools, piling machines, and electric drilling.

The use of compressors in mining extends to above and below ground processes. Underground compressors can help reduce leaks and complicated piping systems. At the surface, the compressor reticulates pressurized air through steel pipes. Compressed air is also an excellent power source for mining due to its flexibility. Air compressors are valuable tools for any company when properly designed, grounded and maintained.

Compressed air is also preferred for mining due to its adaptability and convenience. Air compressors perform well for a variety of mining processes and withstand severe mining wear and tear. They are consistent, efficient and have relatively low replacement parts costs.

Air compressors do require grounding and static prevention to avoid fire hazards. This fire hazard can be reduced with antistatic and fire-resistant materials, thereby keeping the work site safe and operational.