If you ask people what the difference between analog and digital is, most of them will say, "Analog is old-fashioned, digital is modern." That's definitely true, especially since such answers often come from ads about the latest tech, like digital TV, DVDs, or computers.

It's true that analog gas sensors have been around longer than digital ones, but both are still used to detect different gases, like oxygen, carbon dioxide, and methane. Each has its own set of pros and cons, depending on how they're used.

Every Digital Gas Sensor Start from Analog

The development of gas detector technology is linked to various inventions, one of which was made by Naoyoshi Taguchi, a Japanese man who is now the founder of Figaro Engineering Inc., a Japanese gas sensor company that has been operating for more than 50 years. In the 1960s, Taguchi developed an electrochemical gas sensor that produced an analog electrical signal proportional to the concentration of propane in the air. This sensor later became known as the "TGS" (Taguchi Gas Sensors), and it's still widely used today.

Analog electrochemical gas sensors are simple to use. The higher the gas concentration, the greater the electrical signal generated, either in the form of current or voltage. Once the sensor is calibrated, you can use an ammeter or voltmeter to read the signal and determine the level of gas present.

While more modern sensors, like non-dissipative infrared (NDIR) sensors, use more complex tech, the basic idea is still the same. NDIR sensors work by measuring the infrared light absorbed by gas molecules at specific wavelengths. The signal is then converted into an analog signal, amplified, and finally converted into a digital signal using an analog-to-digital converter (ADC).

So, the bottom line is that even though the latest gas sensors have all these fancy new features, they're still basically analog sensors that have an additional ADC so they can be used as digital sensors.

ADC Converter: Link to Digital Gas Sensor

An analog-to-digital converter (ADC) is a key component in digital gas sensors. It takes the analog signal produced by the sensor and converts it into digital form. The conversion process is pretty complex, but the end result is a series of numbers indicating the gas level, which is easily processed by a microprocessor or computer.

In digital sensors, the ADC and the necessary logic are usually built into the microchip on the sensor circuit board. Since they're so close together, digital sensors can respond faster than analog sensors. But of course, there's a catch. These electronic components make digital sensors more expensive than analog sensors.

Analog Signal Output

Analog gas sensors usually produce one of three types of standard output signals to share information about gas levels in an environment. These signals provide continuous data in the form of either current or voltage, which reflects the level of gas concentration detected by the sensor. Some commonly used types of analog signals include:

-

0-10V DC Analog

This system is pretty straightforward. 0V means no gas, while 10V represents 100% gas. It's typically used in HVAC systems. The downside is that a 0V output could mean there's no gas or the sensor has malfunctioned. This type of sensor also requires additional power due to the higher voltage range.

-

0-3V DC Analog

It's similar to the 0-10V output, but better for applications that need less power. The same issues apply, but this type is better if you need an input/output with less power consumption.

-

4-20mA Analog

This is the industry standard you'll see most often. 4mA represents 0% gas and 20mA represents 100%. You'll find this output in systems like PID controllers and SCADA. One advantage of this signal is that if the output is at 0mA, it indicates a problem with the sensor.

Digital Signal Output

Digital signals are different from analog signals because they use binary numbers, which computers and microprocessors can easily process. Digital signals are more precise and flexible, which makes it easier to integrate complex systems and communicate over long distances. Here are some common types of digital outputs used in gas sensors:

-

RS-485

RS-485 lets you connect multiple sensors (slaves) to a central computer (master) with just three cables. RS-485 can support up to 32 sensors, and with the use of additional repeaters, you can expand the system to handle up to 256 sensors. One of the great things about RS-485 is that it can transmit data over long distances—up to 1,200 meters—making it perfect for large sensor networks.

-

I2C (Inter-Integrated Circuit)

I2C is a communication protocol that's used a lot for short-distance connections. It's simpler because it only requires two wires, SCL (clock) and SDA (data). I2C is good for applications that need multiple devices to share data, like sensors, memory cards, or displays.

-

RS-232 Serial

RS-232 is a pretty common standard for digital output, where data is sent over two wires with positive and negative voltages, which are then converted into binary numbers 0 and 1. The advantage is that it allows two-way communication, so sensors can be configured or calibrated remotely. RS-232 is limited to point-to-point communication, meaning only one device can be connected at a time. USB is now more widely used in modern computers, but RS-232 is still used for short-distance, low-speed connections.

-

Modbus

Modbus is a communication protocol that's often used in gas sensors to transmit digital data. It's an open-source standard that allows many devices to communicate in industrial networks. You can use Modbus with RS-485 or RS-232, which lets you manage many sensors (slaves) by a central computer (master) using just one cable or the same network.

Which One is the Best for You?

Before you choose a gas sensor, it's good to know what type of signal output it supports. Standard electrochemical sensors usually only give you a 4-20mA output, while more advanced sensors often give you both analog and digital outputs.

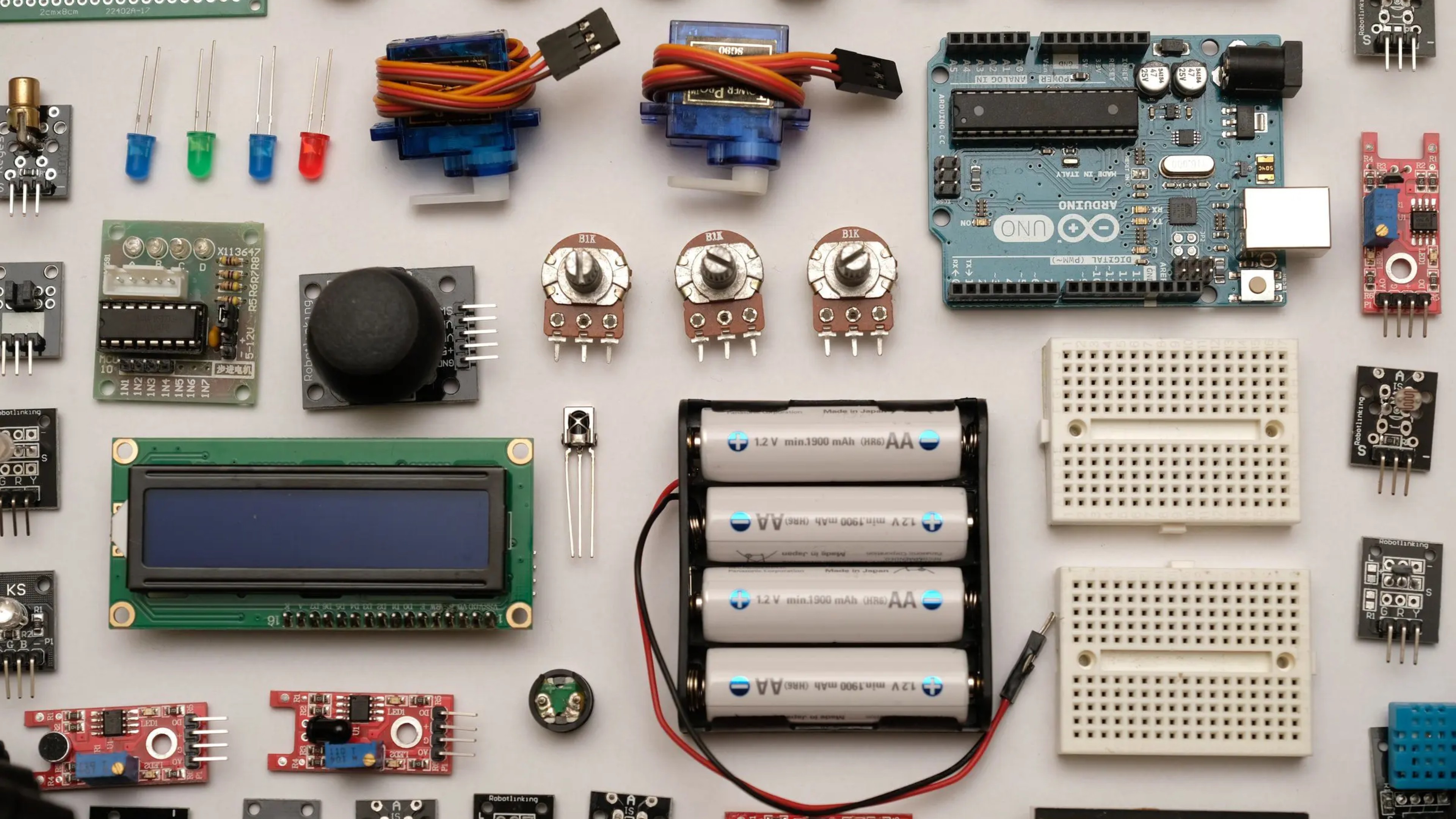

From what we've seen, sensors with RS-232 outputs are the most flexible. They can easily connect to PCs, USB ports, or microprocessors like Raspberry Pi and Arduino. For larger projects that need remote communication or multiple sensors, models with RS-485 or Modbus outputs are a better bet.