.jpg)

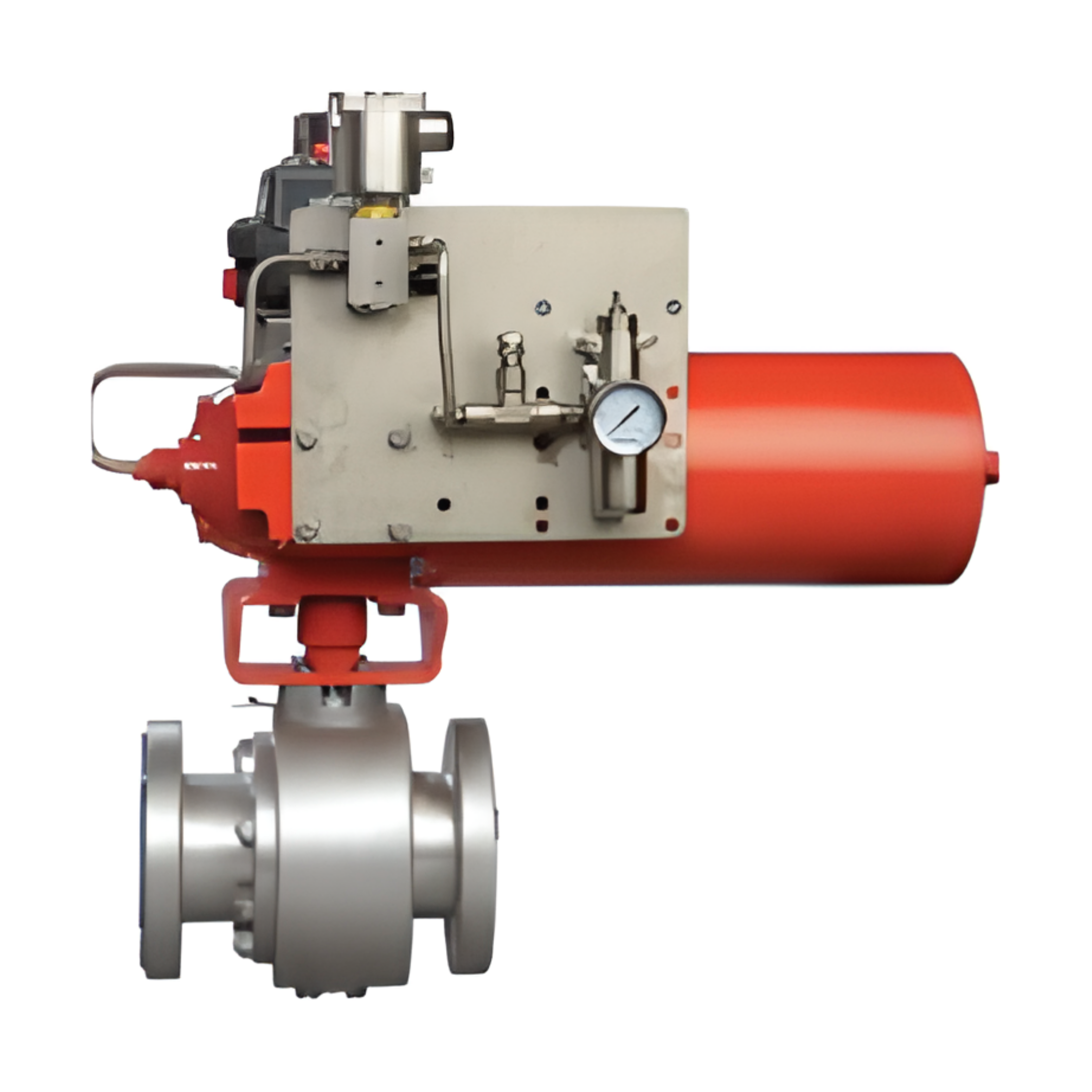

Industrial instrumentation is used to control and monitor conditions including temperature, pressure, and liquid levels in processing facilities, oil refineries, petrochemical plants, oil and gas pipelines, and distribution operations. Common applications of oil and gas instrumentation include monitoring the presence of flammable and combustible gases in production and storage areas and monitoring emissions for pollution control. Instrumentation is also used to monitor and control flow in delivery systems.

There are two types of instrumentation used in equipment monitoring: input and output. Input instruments are used to monitor or measure temperature, flow, pressure, and altitude in equipment including pipes and transport vessels. Output instruments, on the other hand, include controls and alarms that display readings or provide alerts to warn of potentially dangerous situations.

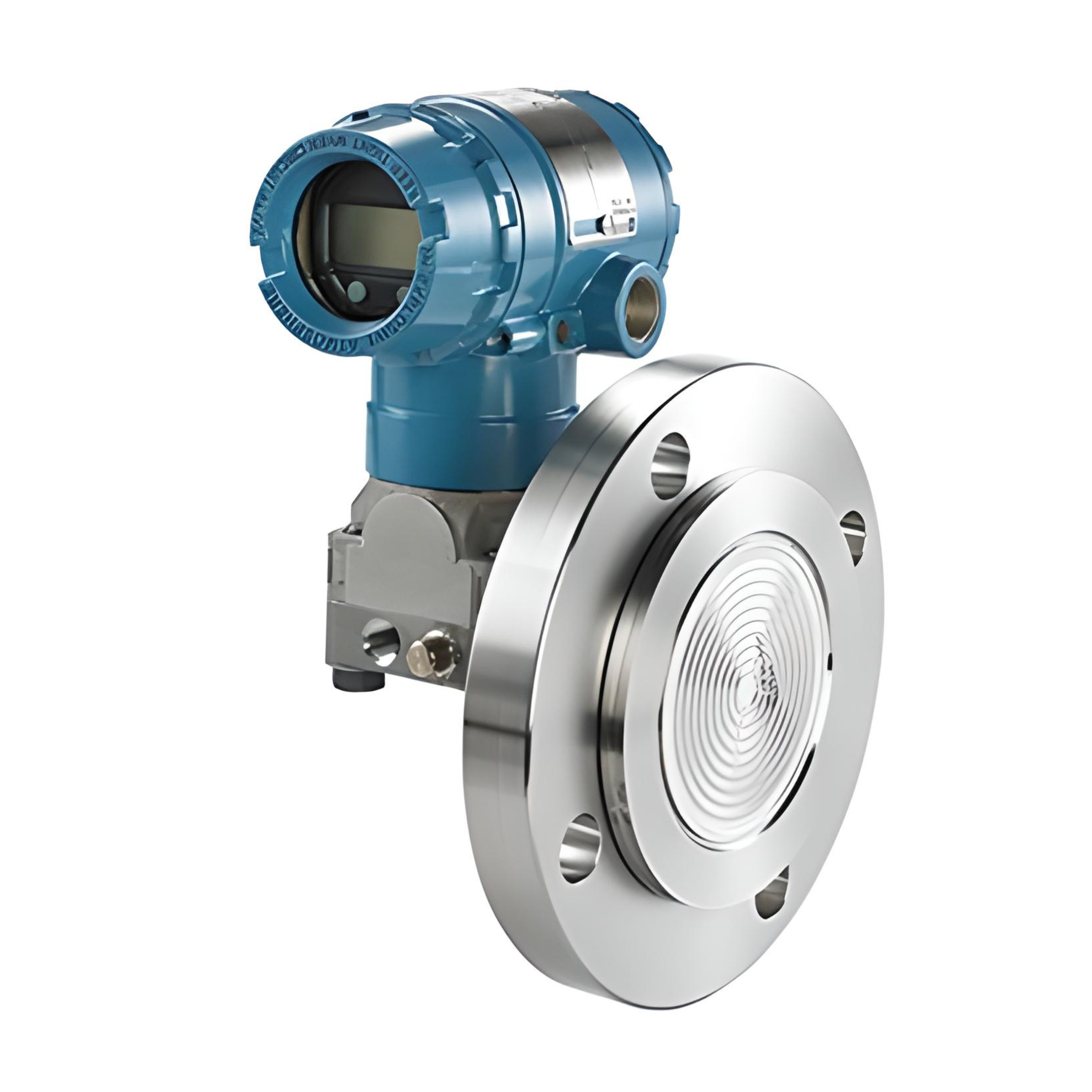

The three main components of industrial instrumentation are sensors, transducers, and transmitters.

- Sensors: measure the physical properties of solids, liquids, or gases. In the oil and gas industry, sensors provide continuous measurements to detect and monitor gas and gas emissions.

- Transducer: converts variations in temperature, pressure, flow, or level into electrical signals that are then captured by a transmitter.

- Transmitter: serves as the interface between the sensor and measurement instrumentation such as level sensors, flow meters, and pressure sensors. This equipment is responsible for sending digital signals to the main control system.

Contact us to discuss the process instrumentation your oil and gas application requires.