When we think of instrumentation, we often picture complex wiring, sensors, and other sophisticated measuring instruments. But did you know that instrumentation plays a much more important role in various industrial sectors? Behind the machines that move, there is instrumentation equipment that keeps everything running smoothly. If you're curious, let's take a deeper look!

Instrumentation is More than Measurement!

So, what is instrumentation? Instrumentation is the science of measuring, monitoring, and controlling industrial processes. It's not just a tool that can measure temperature or pressure. It's much more than that. Instrumentation can provide the data you need to make real-time decisions.

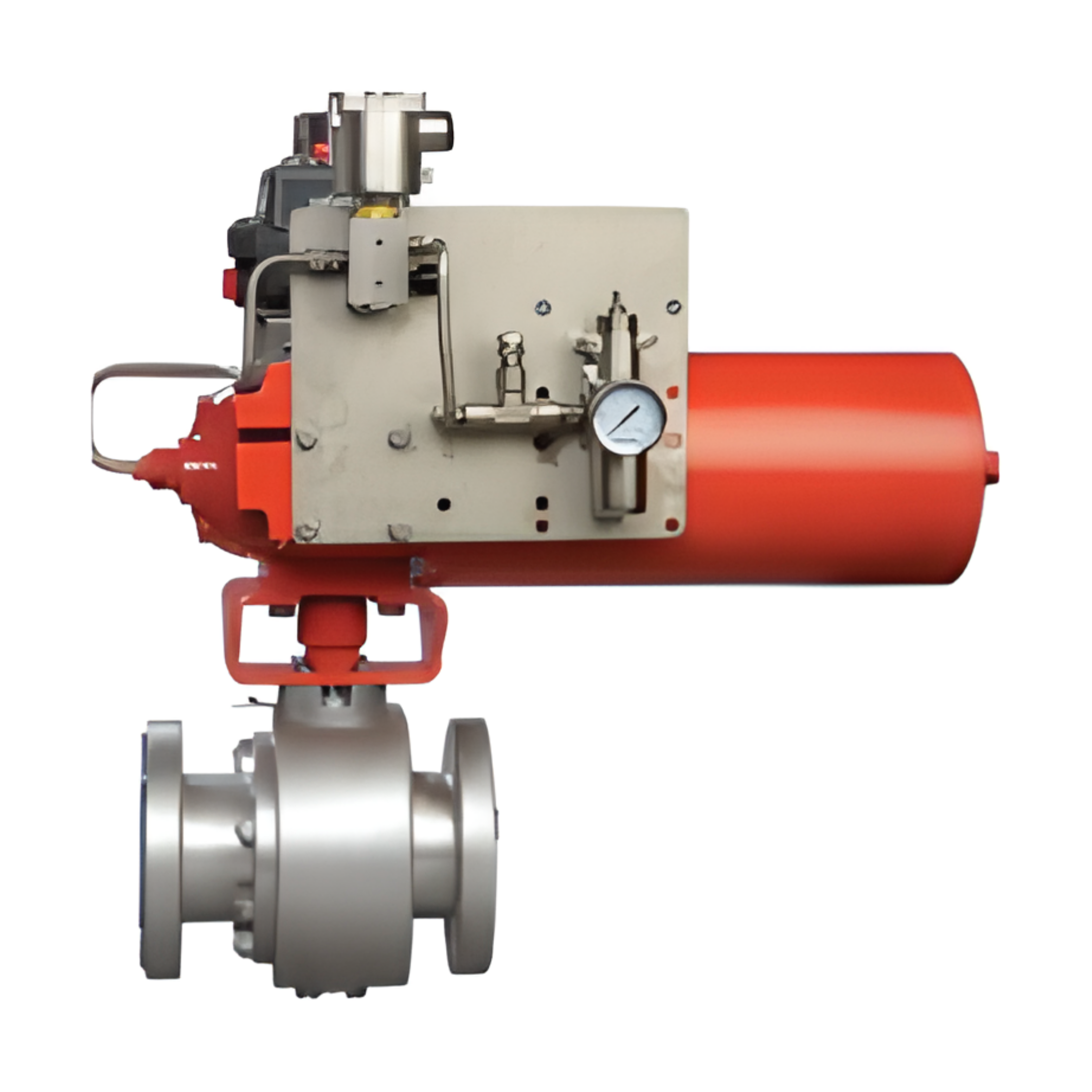

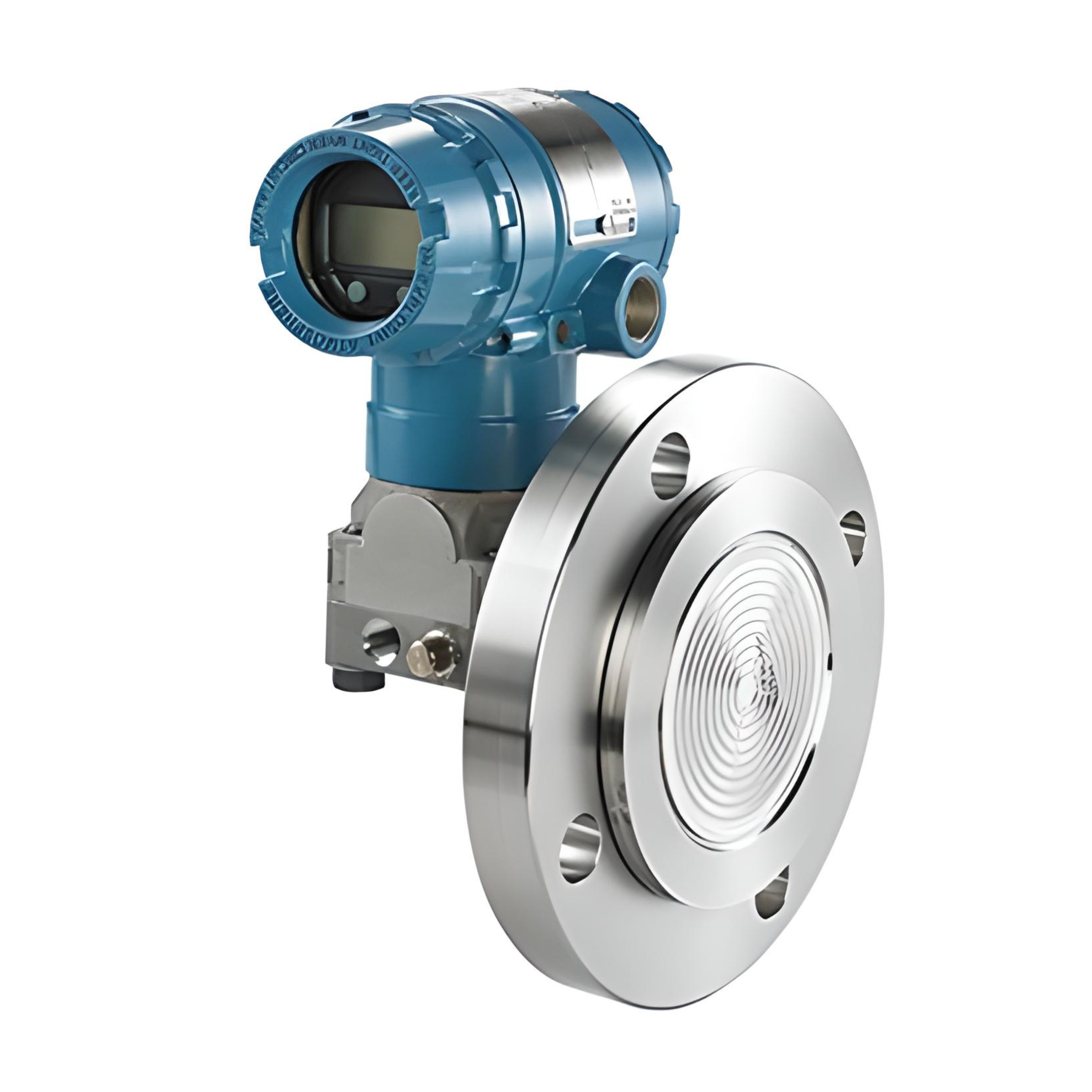

Instrumentation equipment like sensors, transmitters, controllers, and actuators are used to keep an eye on operational processes, which leads to highly efficient end results. Data from Research and Markets shows that the global market for industrial measurement and control systems is set to reach USD 25.12 billion by 2024, with a CAGR (compounded annual growth rate) of 6.85% from 2020 to 2024.

This growth is down to the increasing demand for more sophisticated industrial automation and monitoring tech. The widespread integration of automation technology in various sectors has made instruments more important than ever for optimizing industrial processes, maintaining stability, and enhancing operational safety.

The Big Benefits Behind Invisible Tools

Instrumentation isn't just about taking measurements. It also helps us work more efficiently, stay safe, and take preventive measures. These systems can spot problems before they become big issues. Take energy and manufacturing, for instance. Pressure sensors, flow meters, and vibration detectors are key for spotting potential issues before they become problems.

The latest data from the International Society of Automation (ISA) shows that a whopping 68% of unexpected plant failures are caused by a failure to detect problems early. This can be fixed by putting in more advanced monitoring systems. Meanwhile, a McKinsey study shows that predictive maintenance, supported by instrumentation technology, can significantly reduce machine downtime by 30-50%. These instruments often go unseen by the operator, but they can have a huge impact on plant productivity.

Thanks to advances in technology, we can now access and analyze operational data in real-time and remotely. This allows operators to make informed decisions immediately when deviations in operating parameters occur, preventing larger failures from occurring.

Implementation in Various Industries, From Energy to Manufacturing

The energy sector, especially oil and gas, relies a lot on instruments to keep things running smoothly and safely. Take pressure monitoring instrumentation systems on oil rigs, for instance. They're really important for making sure everything goes as planned and preventing explosions that could put workers in danger. A report from Baker Hughes showed that using more accurate flow measurement tools could save up to USD 10 million a year in some of their drilling operations.

In manufacturing, instrumentation is key to boosting productivity. In food factories, for instance, it's crucial to keep an eye on the temperature to make sure the end product is up to scratch. According to Food Processing, about 30% of food product recalls could be prevented with better temperature control systems, which rely on high-precision instrumentation tools.

In the water treatment sector, instrumentation is used to maintain the quality of clean water. Measuring chemical levels like pH and chlorine is important for the treatment process. According to the Global Water Intelligence report, cities like Singapore have reduced water treatment costs by up to 20% by using IoT-based water monitoring technology. This shows that instrumentation technology has a big impact on improving process efficiency and quality.

Not Just a Tool, But a Key Part of the Industry

Instrumentation has come a long way from just being a measuring device. Thanks to advances in the Internet of Things (IoT) and artificial intelligence (AI), it's now a smart and connected system. Smart sensors can spot patterns in data that might otherwise go unnoticed by humans. For example, they can detect anomalies in engine vibration that indicate early failure.

A new Deloitte report says that by 2025, about 70% of measurement and control processes in industry will be powered by AI and IoT-based automation tech. This means sensors will be able to learn from past data to accurately predict machine conditions, even before a breakdown occurs.

These new technologies are making instrumentation the backbone of modern industrial operations. Companies that adopt the latest instrumentation systems will not only increase productivity and reduce downtime, but will also benefit from improved product quality, reduced waste, and enhanced work safety. For example, in the manufacturing industry, the implementation of IoT-based monitoring systems has enabled early detection of machine breakdowns, thereby avoiding costly production stoppages.

Once we understand the importance of this equipment, we realize that instrumentation is not just a measurement technology. It's a vital part of every industrial process, and we need to appreciate its role in maintaining safety, efficiency, and quality. Plus, this technology is always evolving and adapting to the increasingly complex demands of the industry. Who knows, in the future, you could be an important part of this technology development!