.png)

This tool has an important role for the compressor which functions to dry the water content in the compressed air machine (compressed air). Generally, this system becomes a single process unit with the compressor. Some of the compressed air from the compressor will enter the storage tank and some will be dried using an air dryer.

Often used in large industries, the use of dry air or can be called instrument air is used as a source of actuator propulsion from valves and dampers (pneumatic actuators). In addition, dry air is also used to cover underground cables to avoid short circuits due to the formation of dew.

The air that is dried due to the compressed process will experience a decrease in the dew point. The dew point is the dew point temperature at which the temperature value required to cool a certain amount of air experiences constant pressure. The consumption needs and specifications of the air dryer used affect the decrease in the dew point.

The types of air dryers are as follows:

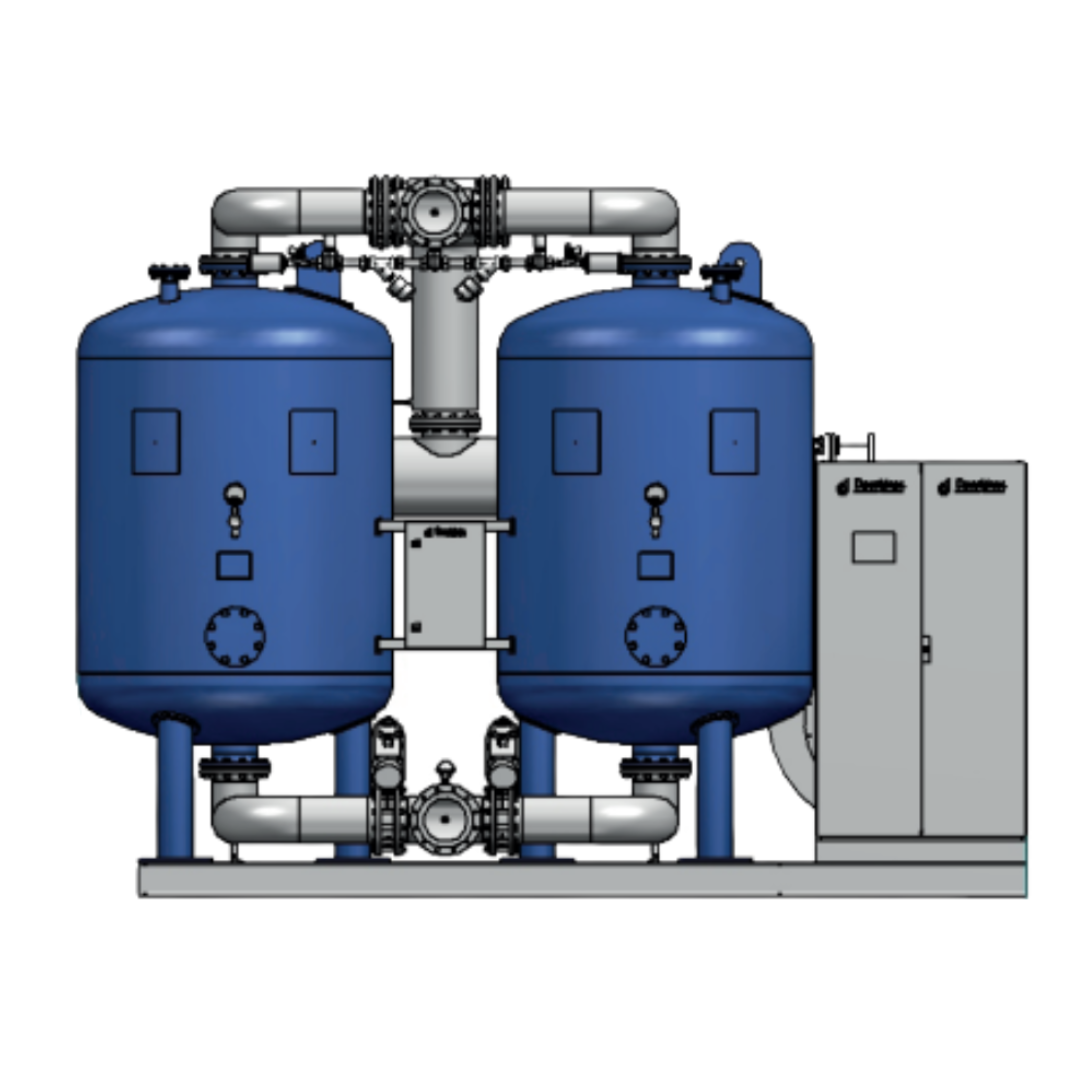

1. Regenerative Desiccant Dryers

Regenerative Desiccant Dryers are tubes containing water vapor absorbing substances such as active molecular alumina or other vapor absorbing materials, but mostly silica gel is used. Compressed air enters the tube through the drying agent and then flows out. When the desiccant reaches the saturation point, it requires a regeneration process. In this regeneration process compressed air should not be flowed into the tube, that's why large industries use twin tower desiccant air dryers that can process regeneration and drying air from each tube in turn. Generally, desiccant air dryers have a dew point of -40 degrees Celsius to produce dry air.

2. Refrigeration Dryer

In the refrigeration dryer, generally 2 heat exchangers are used, namely between the chiller air and the refrigerant and between the air being dried and the chiller air. This process is to dry the air by cooling it. Generally dry air produced has a dew point of 2 degrees Celsius.

3. Deliquescent Dryer

Deliquescent dryer is a tube containing a hygroscopic substance (water absorbent). The water content of the air will be absorbed so that condensation water is formed which needs to be removed. There is a pipe for the discharge at the bottom of the deliquescent dry. It has a dew point that fluctuates depending on the temperature of the inlet air.

4. Membrane Dryer

Membrane dryers are designed to work continuously without stopping. It has an air-drying system that uses membrane dehumidication (moisture absorption). The air that flows into the membrane tube is expelled into dry air then a small portion of the dry air is flowed back into the tube for the regeneration process.