.png)

DLMV 60/15

DONALDSON

PROVEN PERFORMANCE, COMPACT DESIGN

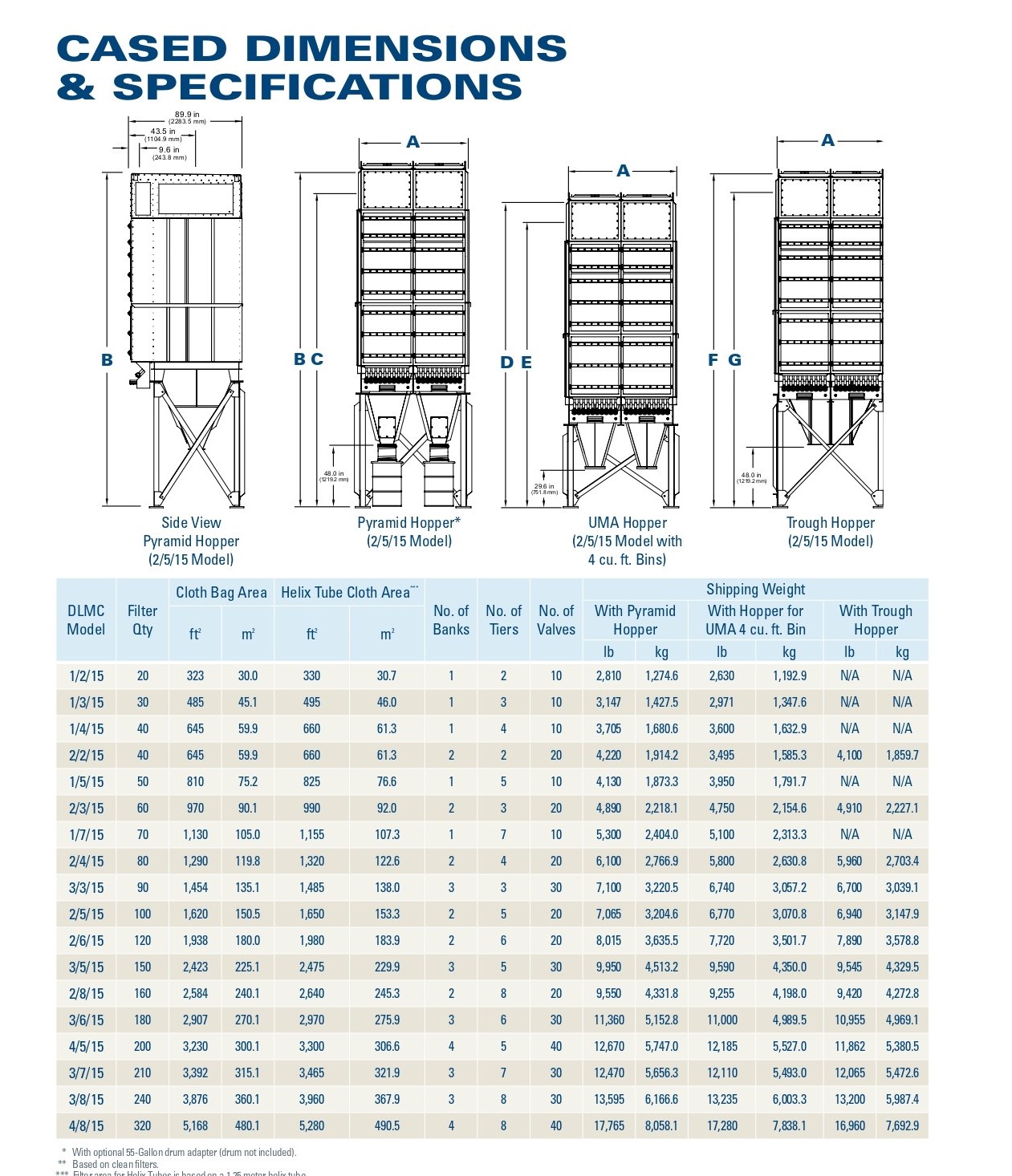

The versatile Donaldson® Torit® Dalamatic series of dust collectors deliver a powerful solution for nearly any dust filtration application. These collectors come in two models: the Dalamatic Cased (DLMC) is a stand alone collector that can be ducted to many different applications; the Dalamatic Insertable (DLMV) is a versatile collector that can be inserted into various applications, such as bins, silos, bunkers, storage vessels or transfer points. Both models are continuous-duty dust collectors designed to handle the most difficult product recovery applications.

THE DALAMATIC FEATURES:

- CONTINUOUS COLLECTION :

- Provides continuous filtration of high dust concentrations at high filtration velocities and constant levels of resistance in almost any industry and application

- COMPACT DESIGN :

- Unique modular design allows for installation in the most space restricted areas. Envelope-shaped bags maximize the amount of media in a given space and allow for increased space between bags, minimizing the chances of bridging

- DURA-LIFE™ BAG FILTERS :

- Provide better surface loading and better pulse cleaning reducing maintenance and operating costs

- HELIX TUBE FILTERS :

- Spunbond polyester media laminated with an ePTFE membrane for even greater filtration efficiency

- VERSATILITY :

- A full range of sizes and types of bags are available for a wide variety of dust collection applications

- 10-YEAR WARRANTY

FLEXIBLE, EFFECTIVE FILTER MEDIA

UNIQUE BAG DESIGN

The Dalamatic advantage is found in the breakthrough technology of Dura-Life bag filters in an envelope shape. The envelope shape provides greater movement of the bag to dislodge more challenging dust cakes during filter pulsing.

• Dust accumulates on the outer surface of the filter bag as air penetrates the media

• The blowpipe (jet tube) injects a burst of compressed air into the bag filter

• Airflow is then briefly reversed, inflating the bag filter and dislodging dust

• The dislodged dust cake falls into the collection hopper for final removal or directly back in the process. The envelope-shaped bag filter, which is mounted on a unique wire frame, ensures optimum airflow and thorough cleaning

SIZES & OPERATIONS

_1681370348.png)

_1681370370.png)

TWO BREAKTHROUGH FILTER OPTIONS FOR YOUR DALAMATICS

DURA-LIFE FILTER BAGS PROVIDE TWICE THE LIFE OVER STANDARD 16 OZ. POLYESTER BAGS

Traditional 16 oz. polyester bags are produced via a needling process that creates larger pores where dust can embed into the fabric, inhibiting cleaning and reducing bag life. Dura-Life bags are engineered with a unique hydroentanglement process that uses water jets to blend the fibers. This process creates a felt with smaller pores which keeps more dust on the surface of the filter, resulting in better pulse cleaning and longer bag life.

_1681370502.png)

HELIX TUBES PROVIDE LONGER LIFE AND REDUCED EMISSIONS

Donaldson Torit helix tubes are constructed of spunbond polyester media laminated with an ePTFE membrane. This combination is more efficient at capturing submicron dust particles. In addition, helix tubes keep dust on the surface of the media which makes pulse cleaning more effective — resulting in a lower average pressure drop, reduced pulse cleaning and longer life.

_1681370521.png)

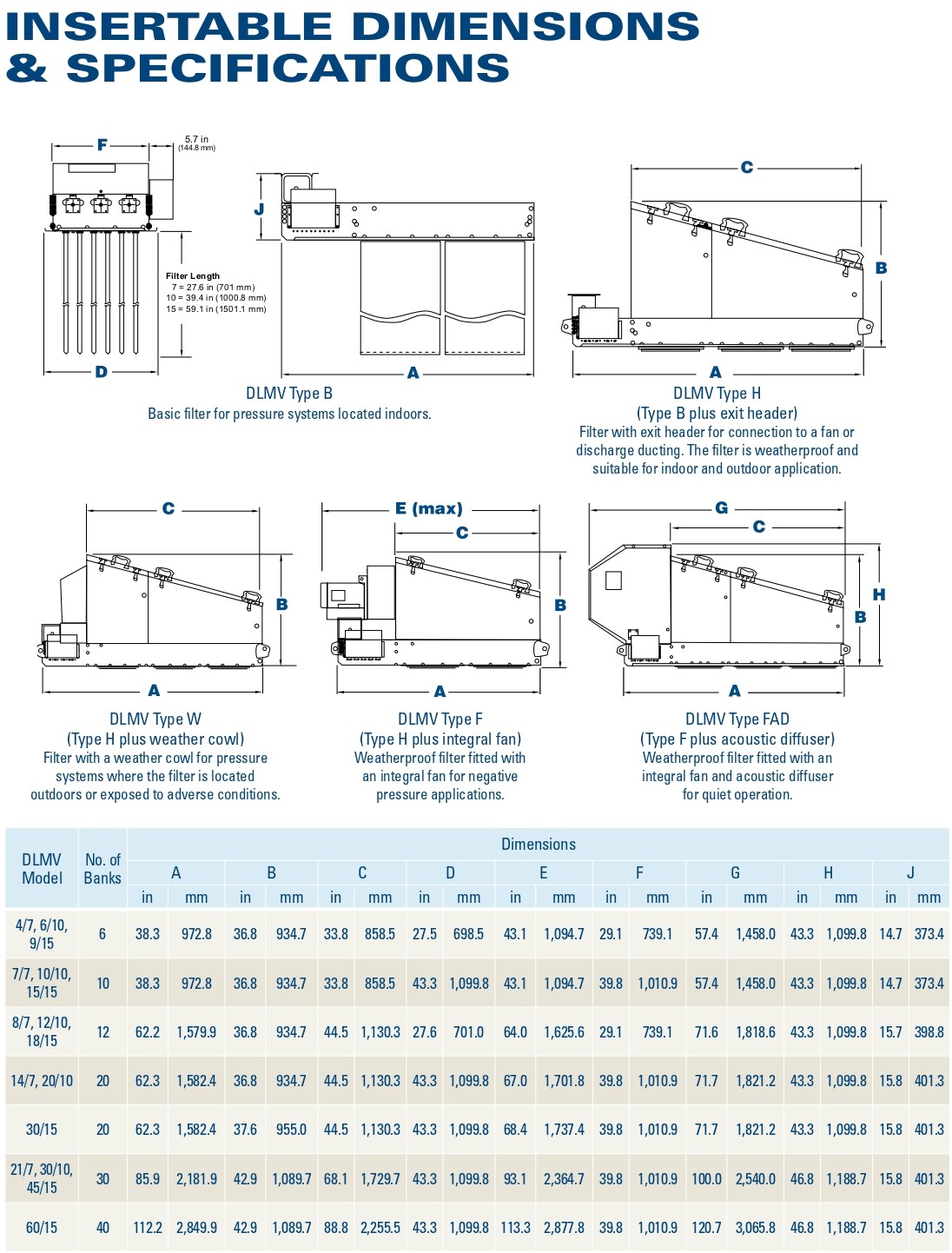

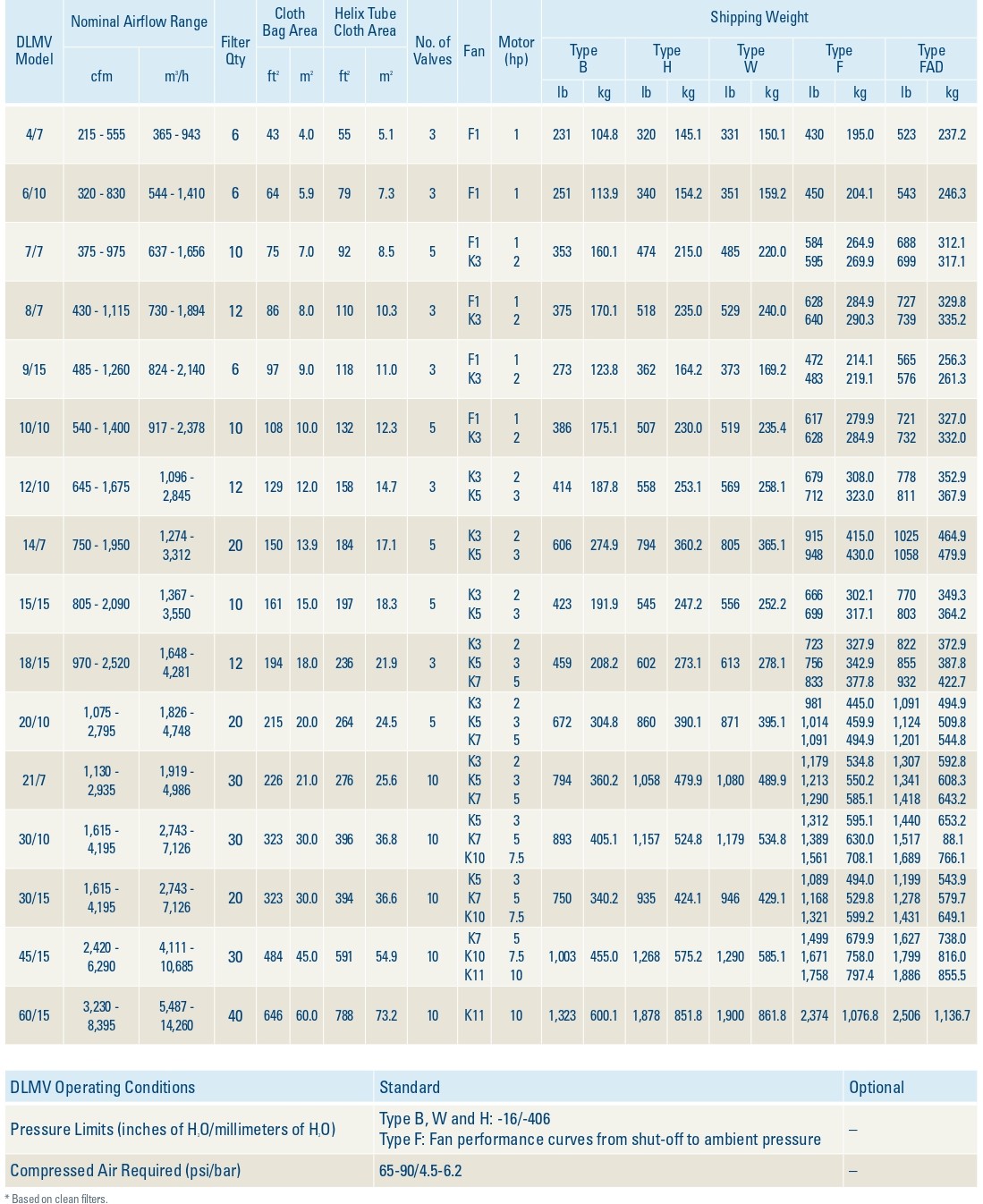

INSERTABLE PERFORMANCE SELECTIONS

TO SELECT THE MOST SUITABLE FAN FOR YOUR APPLICATIONS

- Step 1: Determine the air volume flow (cfm/m3 h) needed to give effective venting and dust control

- Step 2: Estimate pressure or suction (in of H2O/mm of H2O) in the housing in which the dust filter is inserted

- Step 3: Assess the operational pressure drop (in of H2O/mm of H2O) across the clean side and dirty side of the filtering element – usually between 2 to 4 in of H2O (51 to 102 mm of H2O)

- Step 4: The sum of 2 and 3 gives the pressure (in of H2O/mm of H2O) required for fan selection purposes

- Step 5: Consult graph for fan performance available

INSERTABLE WEIGHTED SOUND PRESSURE LEVELS

All readings were taken in semi-reverberant surroundings 3’3” (1.0 meter) radius from the equipment housing and 5’3” (1.6 meters) above base level, using a precision sound level meter and octave filter.

INSERTABLE PERFORMANCE SELECTIONS

TO SELECT THE MOST SUITABLE FAN FOR YOUR APPLICATIONS

- Step 1: Determine the air volume flow (cfm/m3 h) needed to give effective venting and dust control

- Step 2: Estimate pressure or suction (in of H2O/mm of H2O) in the housing in which the dust filter is inserted

- Step 3: Assess the operational pressure drop (in of H2O/mm of H2O) across the clean side and dirty side of the filtering element – usually between 2 to 4 in of H2O (51 to 102 mm of H2O)

- Step 4: The sum of 2 and 3 gives the pressure (in of H2O/mm of H2O) required for fan selection purposes

- Step 5: Consult graph for fan performance available