Have you thought about the impact of your air dryer system? Like a lot of people, you might only think about it when something goes wrong. But the efficiency of your compressed air dryer is really important for your business. Air quality affects how productive you can be and how long your equipment lasts. So, how can you tell it's time to upgrade your air dryer system? Let's look at five signs that indicate it's time for a change.

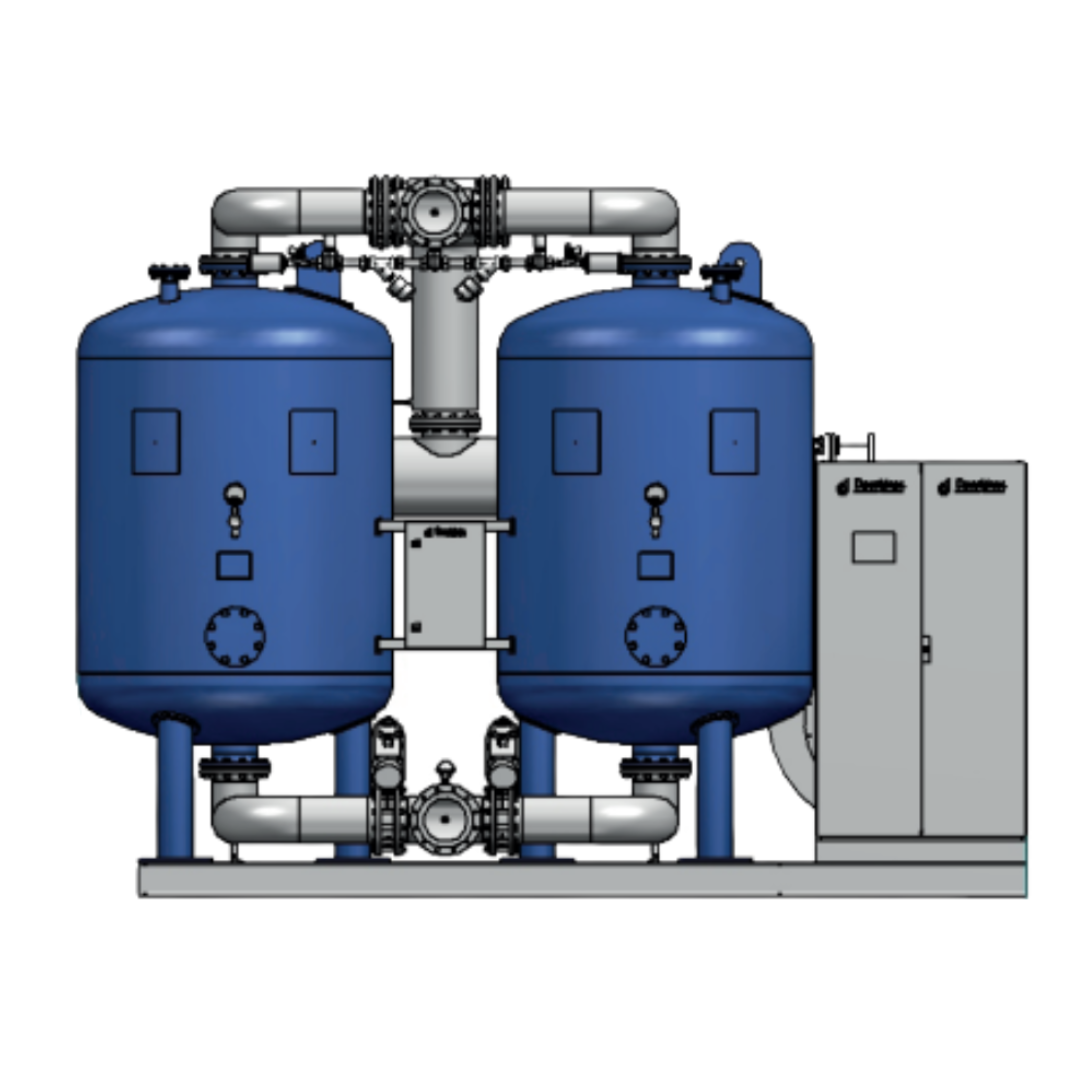

What is Air Dryer?

First, let's talk about what an air dryer system does. In a nutshell, it gets rid of moisture in compressed air, which can cause all kinds of problems if you don't keep an eye on it—like rust and reduced efficiency. Moisture in compressed air can cause some pretty big issues across industries, from manufacturing to pharmaceuticals. Making sure the air is free of moisture is really important, and investing in a reliable air dryer system can help improve operations and prevent costly downtime.

Types of Air Dryer Systems

There are several types of air dryer systems, each with its own unique advantages:

-

Refrigerated Dryers: This type can really cool the air, which is great for getting moisture out and making them ideal for general-purpose applications.

-

Membrane Dryers: These use a semi-permeable membrane to separate moisture from the air, which makes them a great, compact, and efficient solution for all kinds of applications.

-

Heatless Desiccant Dryers: These systems use desiccant materials to absorb moisture from compressed air. They don't need any external heat, so they're pretty energy-efficient. Heatless desiccant dryers are great for applications that require very low dew points.

-

Heated Desiccant Dryers: These dryers use heat to regenerate the desiccant material, which makes them more efficient than heatless models. They're great for processes that need a consistent low dew point and can operate more efficiently than heatless models.

-

Blower Purge Dryers: In this type of dryer, a blower pushes ambient air over the desiccant material during regeneration, effectively drying it out. Blower purge dryers are pretty efficient in terms of energy consumption, and they're commonly used for industrial applications.

-

Cycling Refrigerated Dryers: These dryers utilize a refrigeration process to eliminate moisture, yet they have the capability to turn on and off in order to conserve energy. They adapt their function according to the workload, which increases their energy efficiency compared to non-cycling refrigerated dryers.

-

Dew Point Dependent Control Dryers: These units adjust their operation based on the actual dew point of the compressed air, so you can be sure they'll perform well and use less energy. They can help maintain specific moisture levels in critical applications.

-

Compact Air Dryers: These compact air dryers are great for smaller spaces and applications. They often combine multiple functions in one unit, such as filtering, drying, and pressure regulation, making them ideal for tight spaces.

-

Refrigerated Membrane Dryers: A hybrid system that uses refrigeration and membrane technology to get rid of moisture in compressed air. It's really efficient in some industrial applications.

Choosing the right type for your needs can greatly impact performance and efficiency. If you’re unsure which type to select, we can help you navigate through the options to find the perfect fit for your operations. You can check out our website and see how we can help improve your operations.

Common Air Dryer Systems Application

Air dryers are used in all kinds of industries. From manufacturing and automotive to medical and food processing, lots of businesses need clean and dry air to work properly. It's easy to forget how important compressed air is until something goes wrong. If your air dryers aren't working properly, you could end up with contaminated air, which could affect product quality, safety, and even compliance with regulatory standards.

Take the medical field, for example. If there's moisture in the compressed air, it could lead to bacterial growth, putting patients at risk. We've helped many clients in various sectors make sure their air dryer systems work efficiently and avoid costly downtime.

Knowing How an Air Dryer Works Matters!

Knowing how your air dryer system works can help you figure out when it's time for an upgrade. Typically, air dryers compress, cool, and then reheat air to remove moisture, preventing condensation in your equipment. Over time, wear and tear or operational changes can reduce efficiency. If you notice moisture in your air lines or rising maintenance costs, it could mean your system is underperforming. A reliable air dryer can really improve operations, so let's make sure yours is running efficiently.

Five Signs It’s Time to Upgrade Your Air Dryer System

It's really important to keep an eye on your air dryer system so you can avoid long breakdowns. There are at least five signs you should look out for so you know when it's time to upgrade. Here they are:

Sign 1: Maintenance Costs are Rising High

If you've noticed your maintenance bills going up, it might be time to take a look at your air dryer system. Older or less efficient systems tend to use more energy as they struggle to get rid of moisture, which can drive up costs. Professional team at PT. Vando Teknik Solusi often suggest an energy audit to see if your air dryer is causing the problem. Upgrading to a more energy-efficient system can lead to long-term savings.

Sign 2: Air Quality Decreases Significantly

Have you noticed more moisture or contaminants in your compressed air? If so, it could be a sign that your air dryer system isn't working as well as it should. Over time, air dryers lose their efficiency, which can lead to poor air quality—and that can be a big problem in industries like food processing or pharmaceuticals. Upgrading to a high-performance system, such as those from PT Vando Teknik Solusi, can help you maintain strict air quality standards and ensure reliable operations.

Sign 3: Maintenance Issues Occur Frequently

If you're constantly scheduling maintenance for your air dryer, it might be time for an upgrade. Frequent breakdowns not only cost you in repairs but also in downtime, which can really impact productivity. With new and improved air dryer technology, modern systems are built to be more reliable and require less maintenance. At PT Vando Teknik Solusi, we offer systems designed to minimize downtime and reduce maintenance needs.

Sign 4: Overheating and Noise

Is your air dryer system getting louder or overheating? These are signs that your unit is struggling to perform. Older systems often overheat because they can't handle the load as efficiently as they used to. If you're hearing unusual noises or dealing with constant overheating, it might be time to explore newer models that are designed to operate more quietly and efficiently.

Sign 5: System Age

The age of your air dryer system is a big factor to think about. If your unit is over 10 years old, it's probably time to think about an upgrade. Newer models are more energy-efficient and reliable, which helps you avoid unexpected breakdowns. Our clients significantly improve their operational efficiency by upgrading to a newer air dryer system, especially in industries that rely heavily on compressed air.

Are you noticing any of these signs? It might be time to reach out to us at PT Vando Teknik Solusi. We've got a range of solutions that are tailored to meet your specific needs, from industrial filtration systems to medical air systems. Don't let an outdated air dryer system hold you back. Check out our website to explore our products and services and see how we can help improve your operations.