Why's Dry Air Important? Let's Find Out!

Ever feel like the air is too humid and making you uncomfortable? Well, in the industrial world, humid air not only makes us uncomfortable, but it can also cause a lot of serious problems. If there's too much humidity in the machine, it can damage the equipment, reduce product quality, and even mess with production efficiency. That's where desiccant dryers come in — they're not just a fix, they're a total lifesaver.

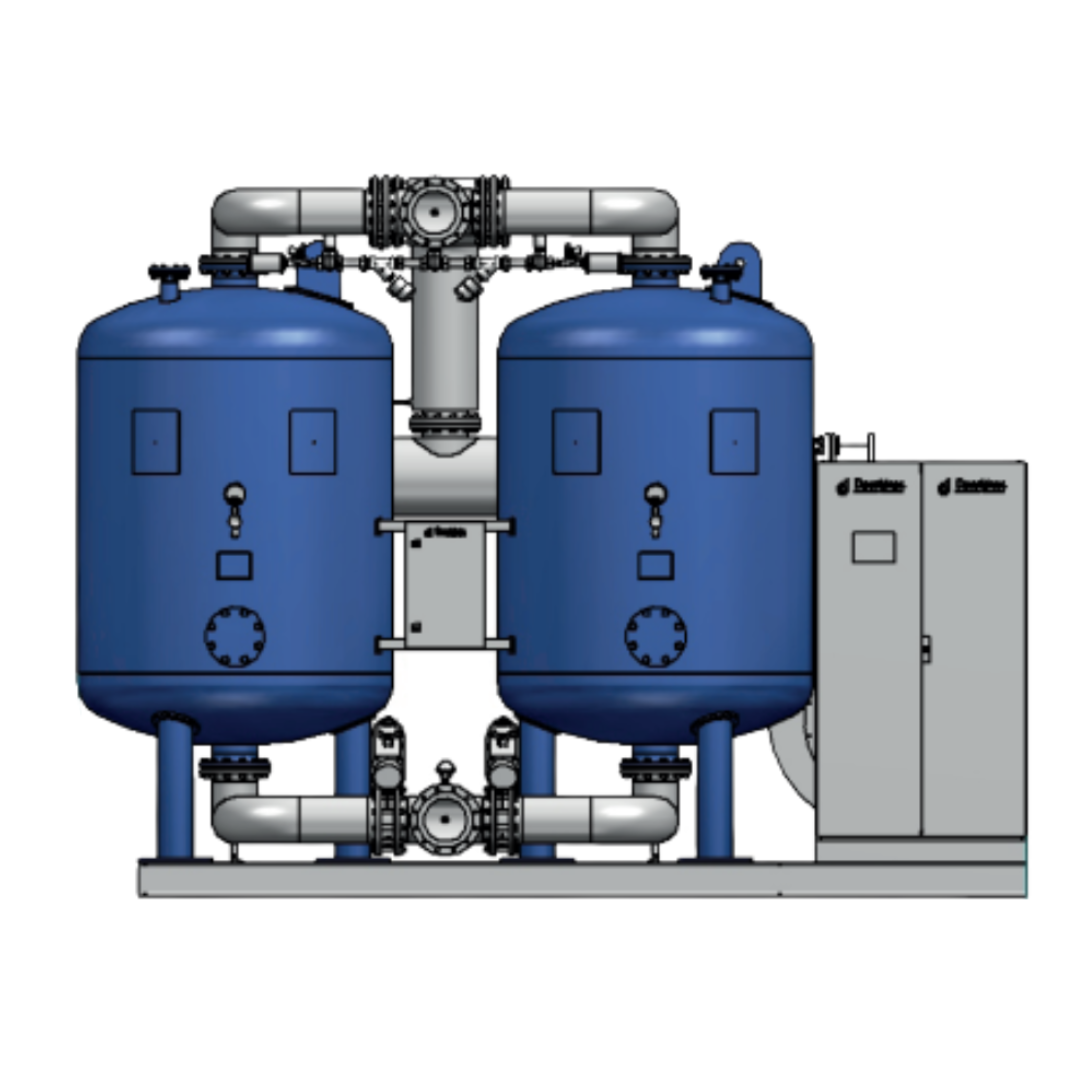

A desiccant dryer is a device that's made to get rid of as much moisture in the air as possible. For anyone working in industry, this is a game-changer that you can't afford to miss. With much drier air, you get better production results and avoid huge losses due to equipment damage. So, get ready to learn more about this cutting-edge technology!

What is a Desiccant Dryer and Why Should You Care?

Hey, have you ever heard of a desiccant dryer? If not, then you should definitely check it out. For those of you in the industrial world, a desiccant dryer is an essential device used to dehumidify the air as much as possible. We all know that humid air can be a big problem for your industry, especially if you need your production to be completely dry. A desiccant dryer is the perfect solution for this problem. With its advanced technology, it can deliver air with almost zero moisture.

Desiccant dryers are also key to keeping industrial operations efficient. Too much humidity in the production process can cause all kinds of problems, like damage to equipment or lower-quality products. Using a desiccant dryer can prevent all of that. This tool is also very flexible and works for all kinds of applications, from small to large scale. So, there's no reason to overlook the importance of this tool in keeping the production process running smoothly.

What's make Desiccant dryers even more cooler is because they help reduce downtime in the production process. This tool lets you forget about air humidity messing with your production. Production runs more smoothly, and you can focus on improving product quality. In the long run, this is a huge advantage that's hard to match with other tools.

How Does a Desiccant Dryer Work? Let's Take a Peek!

Desiccant dryers work in a pretty clever and unique way. They use a desiccant material, usually silica gel or activated alumina, to absorb water molecules from the air. Wet air goes into the dryer, and once it comes out, it's super dry. This means there's no more moisture to disrupt the production process or damage equipment. That makes desiccant dryers a mainstay in many industries, from pharmaceuticals to food and beverages. In some cases, they're actually essential for keeping the quality standards super high.

Modern desiccant dryers are pretty cool. They've got advanced technology to make them more efficient. Some models use smart sensors to keep an eye on the humidity levels. This helps make sure the appliance is working the way it should, without wasting energy. That means desiccant dryers are efficient at drying air, and they're also good for the environment. There are a lot of benefits to using this appliance.

There are also desiccant dryers made for certain uses, like large-capacity models for factories or portable ones for field use. So no matter what you need, you'll find a model that works. Just make sure you talk to a trusted vendor to get the best recommendation.

What Makes a Desiccant Dryer More Special Than the Others?

You might be wondering what makes a desiccant dryer so special compared to other types of dryers. One of its big advantages is its ability to dry air to very low humidity levels. The air produced can even reach dew points as low as -40°C or even -70°C for certain models. Air that cold must be moisture-free, right? A desiccant dryer is way better than a refrigerated dryer in this area. So, when you really need dry air, a desiccant dryer is the best choice.

Another perk is that they're more compact and durable. Some desiccant dryer models can handle extreme conditions, like high temperatures or low air pressure, making them reliable in tough situations. No matter what your industry needs, a desiccant dryer is a solid investment.

Desiccant dryers are also known to be more energy-efficient in the long run, even if you have to spend quite a lot to buy them at first. But if you do the math, you'll see that they're actually quite cost-effective. Many modern models are also equipped with an automatic regeneration feature that allows the drying material to be used repeatedly without the need for frequent replacement. Just make sure you keep up with regular maintenance to keep the equipment running smoothly.

The Impact of Humid Air? Don't Let It Harm Your Production!

When it comes to industrial needs, a lot of industrial equipment is very sensitive to moisture. Take the pharmaceutical industry, for example. Moisture can make drug ingredients clump together and reduce their quality, which can directly impact the effectiveness of the drug. Not to mention the food industry, where humid air can accelerate spoilage or mold growth. Using a desiccant dryer can easily solve these problems. The dry air helps keep the quality of the product at its peak and extends its shelf life.

But, on the flip side, humid air can also mess with the performance of electrical and electronic equipment. Just think about it: if moisture gets into electrical components, there's a big risk of a short circuit. That's dangerous and can cause a lot of damage. With a desiccant dryer, you can reduce these risks, so your equipment can stay durable and safe to use. So, don't underestimate the importance of dry air in keeping your industry running smoothly.

Desiccant dryers are used in all kinds of places. You'll find them in big factories, but also in labs and medical facilities. They're used to keep surgical tools sterile and free from moisture, which is crucial in these settings. They're also used in the tech industry, like in the production of semiconductors and advanced electronic devices. In this high-tech world, even the tiniest bit of moisture can mess up the whole production process.

Finally, desiccant dryers are also starting to be used in households for specific things, like reducing humidity in storage rooms or preventing mold growth in certain areas. With technology becoming more affordable, this tool is now accessible to anyone who needs it.