Ever feel confused when you're trying to choose the right dryer for your industrial operations? Don't worry, you're not the only one! Choosing an air dryer might seem simple, but it plays an important role in keeping your work efficient and your products high-quality. This article is designed to provide a complete guide so that you can understand and choose the most suitable air dryer for your business needs. Let's take a closer look!

The Importance of Air Dryer in Industrial Operations

In the industrial world, an air dryer is not just an add-on, it's a necessity. It removes moisture from compressed air, which if left unchecked can cause all kinds of serious problems. Water vapor in air systems can trigger corrosion, reduce equipment performance, and even cause operational failures. So choosing the right air dryer is about more than efficiency. It's also about protecting your investment and keeping your production going.

Types of Air Dryer and Mechanism of Work

There are a few different types of air dryers out there, and they can be used to meet the different needs of the industry. The two most common are refrigerated air dryers and desiccant air dryers. Refrigerated air dryers work by cooling compressed air. The air is cooled until water vapor condenses and separates. This process is similar to how a refrigerator works at home. It's a popular choice because it's energy-efficient, affordable, and simple to maintain. If your industrial needs don't require air with very low moisture content, this type is an efficient and economical choice.

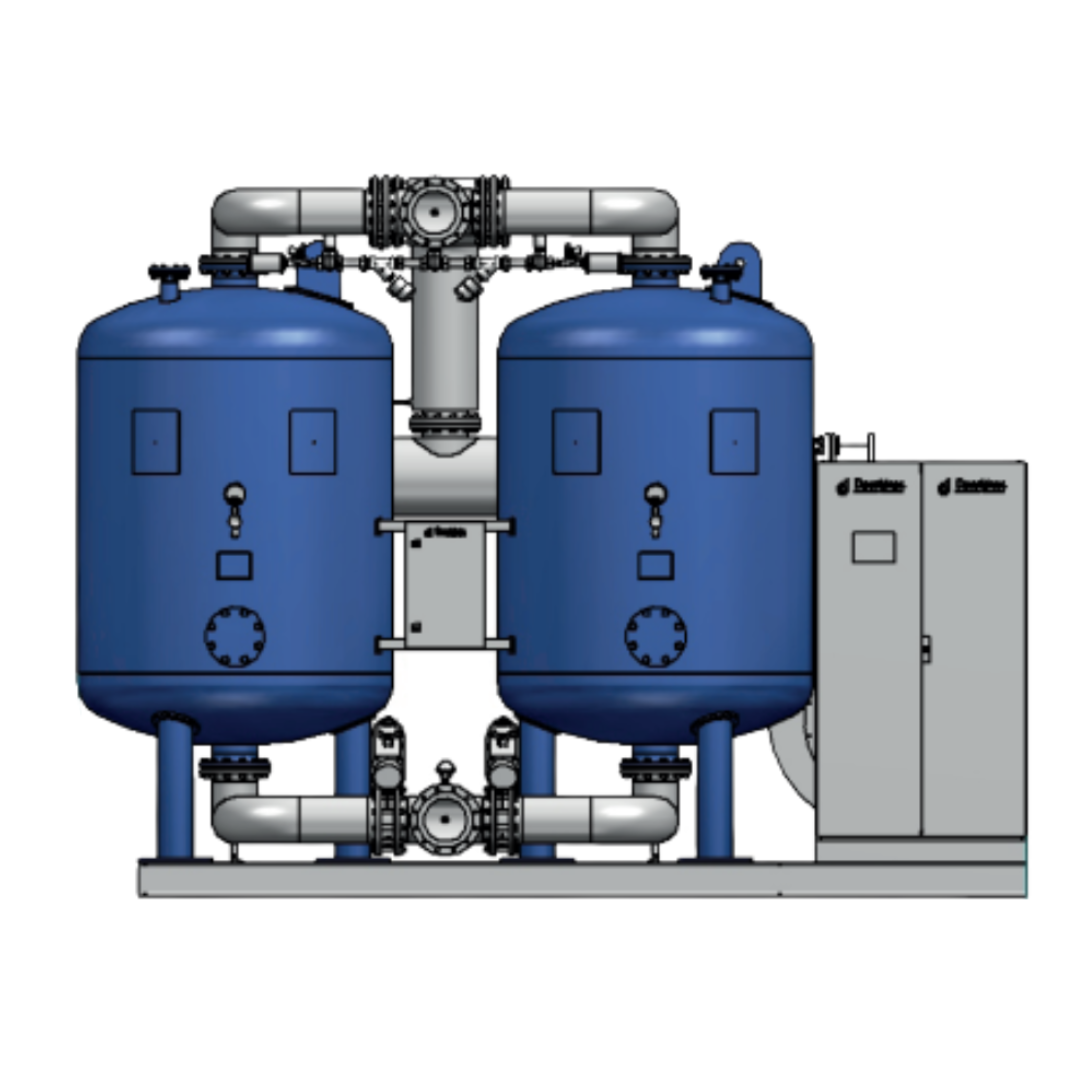

In the other hand, Desiccant air dryers use materials like silica gel or activated alumina to remove moisture. This process makes air that's really dry, with dew points down to -40°C or lower. Because of this, desiccant air dryers are great for sensitive applications like pharmaceuticals, food, or medical devices. In the food industry, for example, low humidity is key to maintaining product quality and hygiene.

Also If you need something more complex, we've got hybrid air dryers that combine the efficiency of a refrigerated air dryer with the maximum drying capability of a desiccant air dryer. They strike a nice balance between high performance and cost efficiency.

A Guide to Picking the Right Air Dryer for You

When picking an air dryer, the first step is to figure out the specific needs of the industry or application. If it's just for simple pneumatic tools, a refrigerated air dryer will do the job. But for applications that need air without any moisture at all, like in labs or the pharmaceutical industry, a desiccant air dryer is a better choice.

You also need to adjust the capacity of the appliance to match the airflow needs of the compressor. For example, if your compressor can handle 20 CFM (Cubic Feet per Minute), make sure your air dryer can handle that or more. A tool that's too small will quickly break down because it's working beyond its capacity, while a tool that's too large will waste energy.

Things to Consider When Choosing an Air Dryer

There's more to think about than just type and capacity when you're picking an air dryer to make sure it's efficient and durable. One thing to consider is energy efficiency. A lot of modern air dryers have energy-saving features like automatic controls that adjust how the appliance works based on what you need. This saves on electricity costs and helps reduce your company's carbon footprint.

Where your factory is located matters a lot, too. If it's in a high temperature area, you'll need an air dryer that can handle the heat. Some modern refrigerated air dryers can operate at up to 45°C. And don't forget to think about the noise level of the dryer. A lot of people forget about this, but it's really important to have a comfortable work environment. Air dryers with soundproofing are a great choice for factories where silent operation is a must.

Lastly, think about how much it'll cost to maintain the equipment. Refrigerated air dryers are usually easier to maintain since they have simple components. On the other hand, desiccant air dryers require you to replace the absorbent media regularly. Some of the latest models have an automatic regeneration feature that can reduce the frequency of maintenance and extend the life of the appliance.

Consultation and Final Steps Before Purchase

To make the right choice, it's a good idea to talk to a trusted air dryer provider. Lots of vendors offer a free air demand analysis service. This includes measurements of airflow, pressure, and humidity levels. This analysis is very helpful to figure out the most suitable appliance type and specifications.

Besides consulting, it's a good idea to check out reviews from other users and talk to your colleagues who've used one. People's first-hand experience can give you some useful tips that you won't find in the product's specs.

Investing in the right air dryer can make or break your business. Make sure to get it installed by someone who knows what they're doing and keep up with regular maintenance. That way, you can get the most out of your equipment and make it last. So, are you ready to pick the perfect air dryer for your business?