In the industrial sector, making sure machines are at their best is no longer just a nice-to-have. You probably already know how important it is to keep production flowing smoothly, but there's one device that's especially crucial: the air dryer. It might be small, but the air dryer is a key player in keeping the air dry, so the machine can "breathe" without any unwanted moisture.

Air dryers are a must for keeping the system's air moisture-free. If the air is too humid, it can cause all kinds of problems, like corrosion, reduced engine performance, and even damage the engine parts inside. Imagine a machine in your factory suddenly stopping because there's water in the compressor. This kind of downtime is not just annoying, but it also costs a lot. Using an air dryer can stop this from happening, so the machine keeps working at its best, and production can keep going without any problems.

Why are Air Dryers Important to Industry?

In the world of industrial machinery and equipment, we're always looking for ways to make things more durable. It might seem like a harmless gas, but humidity in the air can cause some pretty serious problems if it gets into the system. When humid air gets into the system, water particles can get trapped and build up, especially in the areas around the compressors and pipes. This leads to condensation, and as the temperature changes, the humid air can turn into harmful water vapor.

What can you do to avoid this happening? The air dryer is the answer. The main thing an air dryer does is reduce the moisture in the air used in pneumatic and compressor systems. The most common type of air dryer is the refrigerated air dryer. This method lowers the air temperature until the moisture condenses into dew, which can then leave the air before it goes into the system. It's very energy-efficient and great for sectors that need low humidity levels, but not too low.

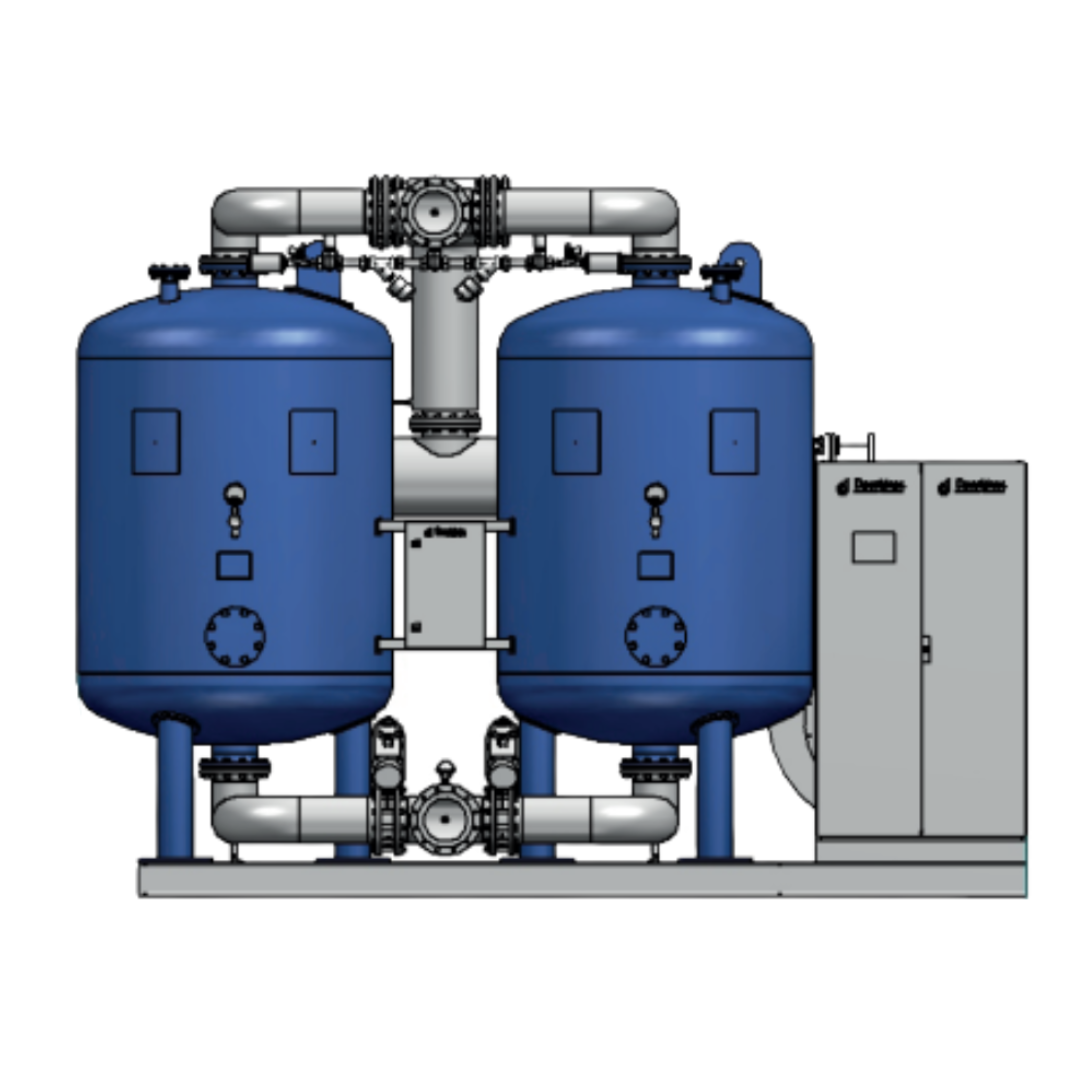

If you need to dry things really well, a desiccant dryer could be a good choice. These dryers use desiccant substances to capture water vapor, so the air they give out is really dry. This makes them great for things like pharmaceuticals, labs, or electronics, where even a little moisture can make a big difference in the end product.

If you're looking for the best way to keep your industrial system clean, we at PT Vando Teknik Solusi can help. We're an official distributor of Donaldson Company, so we've got a great selection of top-notch air dryers for different industrial sectors. With our know-how and commitment to great service, we guarantee that every product we provide will make your equipment more efficient and last longer.

Positive Effects of Air Dryer Use in Industry

Picking the right air dryer can give you a lot of benefits beyond just keeping your equipment in good shape. One of the best things about it is that it can make your machines last longer. Why does this happen? When there's less moisture in the air, it's less likely that the metal parts in the system will corrode. This means that your machines can run for a longer time without needing a lot of repairs. This can also help you save money on maintenance, which is always a good thing if you're trying to control your operational budget.

Air dryers are great for keeping machines in good shape, but they also affect product quality. In food, drink, pharmaceuticals, and chemical manufacturing, it's really important to make sure the air is free from water particles that could contaminate the product. For example, in the drug industry, microbial contamination can easily happen in a moist environment. Using a working air dryer can really help to reduce this risk.

On the flip side, production efficiency gets a big boost. Machines that don't have moisture issues run more smoothly, which directly affects production rates. The time spent on water infiltration issues is cut way down, keeping production high. This is especially important in facilities with high production, because even a few minutes of downtime can throw off the whole production schedule.

When it comes to using an air dryer, it's important to choose the right one for your needs. For example, if you're running a factory with basic requirements like metal or textile production, a refrigerated air dryer might be enough. But if you're working in an environment that's very sensitive to moisture, like electronic or medical component production, a desiccant dryer is a great option. This machine can remove moisture from the air, which can damage or impair the product.

At PT Vando Teknik Solusi, we guarantee that you'll get air dryer products from Donaldson that are tailored to your industry's specific needs. We're confident that with high-quality equipment like ours, you can ensure that each machine in your production workflow operates more efficiently, with reduced risks and improved cost-effectiveness.

Data and Interesting Facts About Air Dryer

Recent stats show that there's a growing need for air dryers worldwide. A report from an industry research group says that demand for air dryers has risen by about 5% a year in recent years. This shows that more and more businesses are realizing how important it is to keep air quality in their pneumatic systems up to scratch.

We're seeing more and more companies adopting air dryers that are more energy-efficient. Lots of air dryer manufacturers are currently trying to create technologies that use less power, which will help to lower electricity costs while maintaining performance. Several new models are now outfitted with automatic monitoring systems that can adjust energy usage according to what's needed at the moment.

If you're looking for a reliable, high-quality air dryer that meets the toughest industry standards, PT Vando Teknik Solusi has got you covered with air dryer products from Donaldson Company. You'll get a clean air solution that's effective, efficient, and built to last.