When it comes to air pollution control systems, there are a few technologies that people often talk about: baghouses, cartridges, cyclones, and wet scrubbers. Each has its pros and cons, but which one is really best for your needs? Let's take a closer look so you can make the right decision.

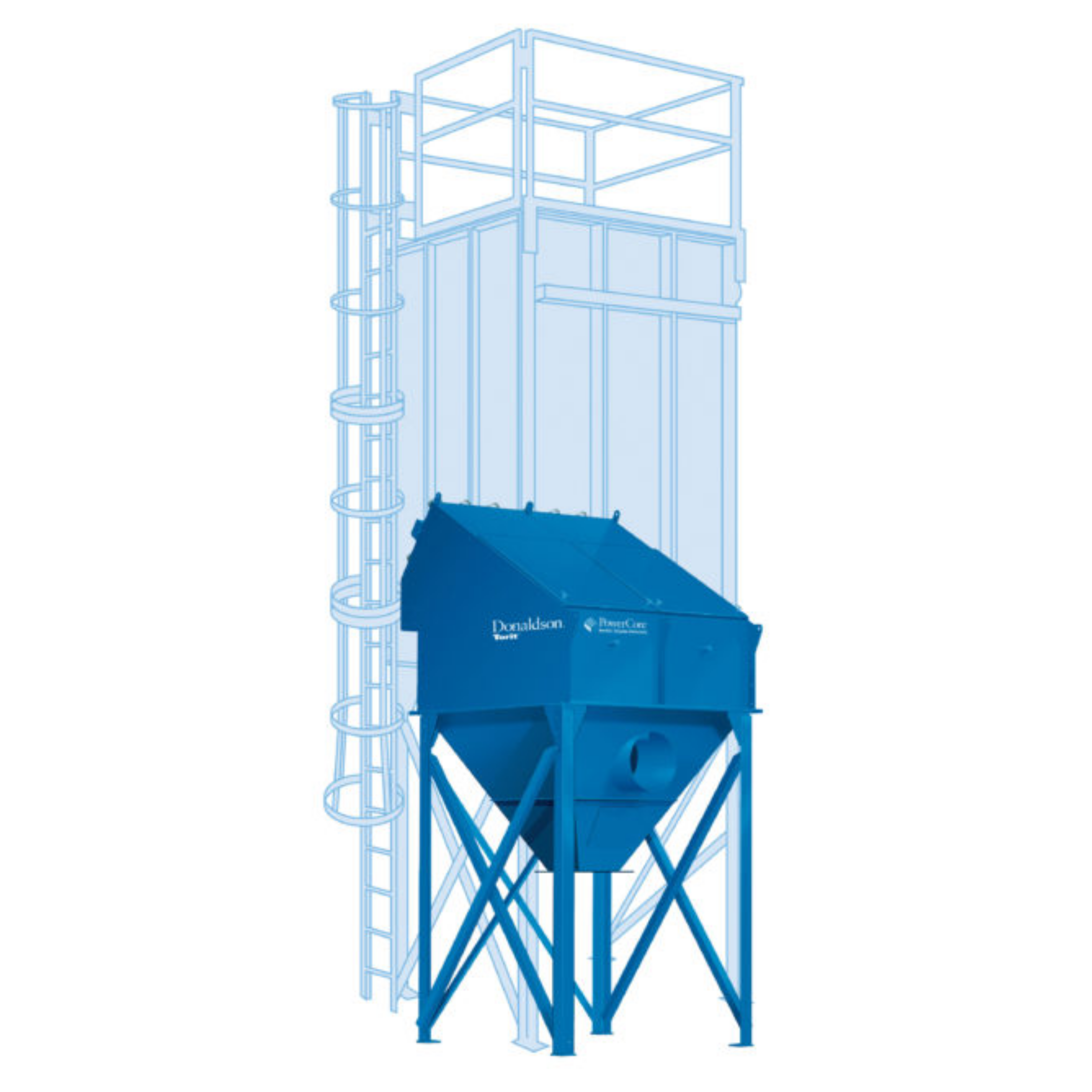

Baghouse Dust Collector, the Perfect Solution for Fine Dust

Baghouse-type dust collectors are some of the most popular dust control systems out there, especially for dealing with fine particles. This system uses a series of filter bags that capture dust particles as dirty air passes through them. It's great for industries that produce a lot of dust, like cement plants, power plants, or chemical plants.

One of the perks of the baghouse type dust collector is how well it handles dust, with an efficiency of up to 99.9%. This makes it a great choice for industries with strict emission standards. But, this system needs regular maintenance since the filter bags can get clogged or damaged over time. You also have to think about the cost of replacing the filters, since they're pretty pricey.

Even so, we think this type of dust collector would still be a solid choice if you're looking for a system you can count on for the long term. Also, the technology keeps getting better with more durable filters and automatic cleaning systems that reduce the need for manual maintenance.

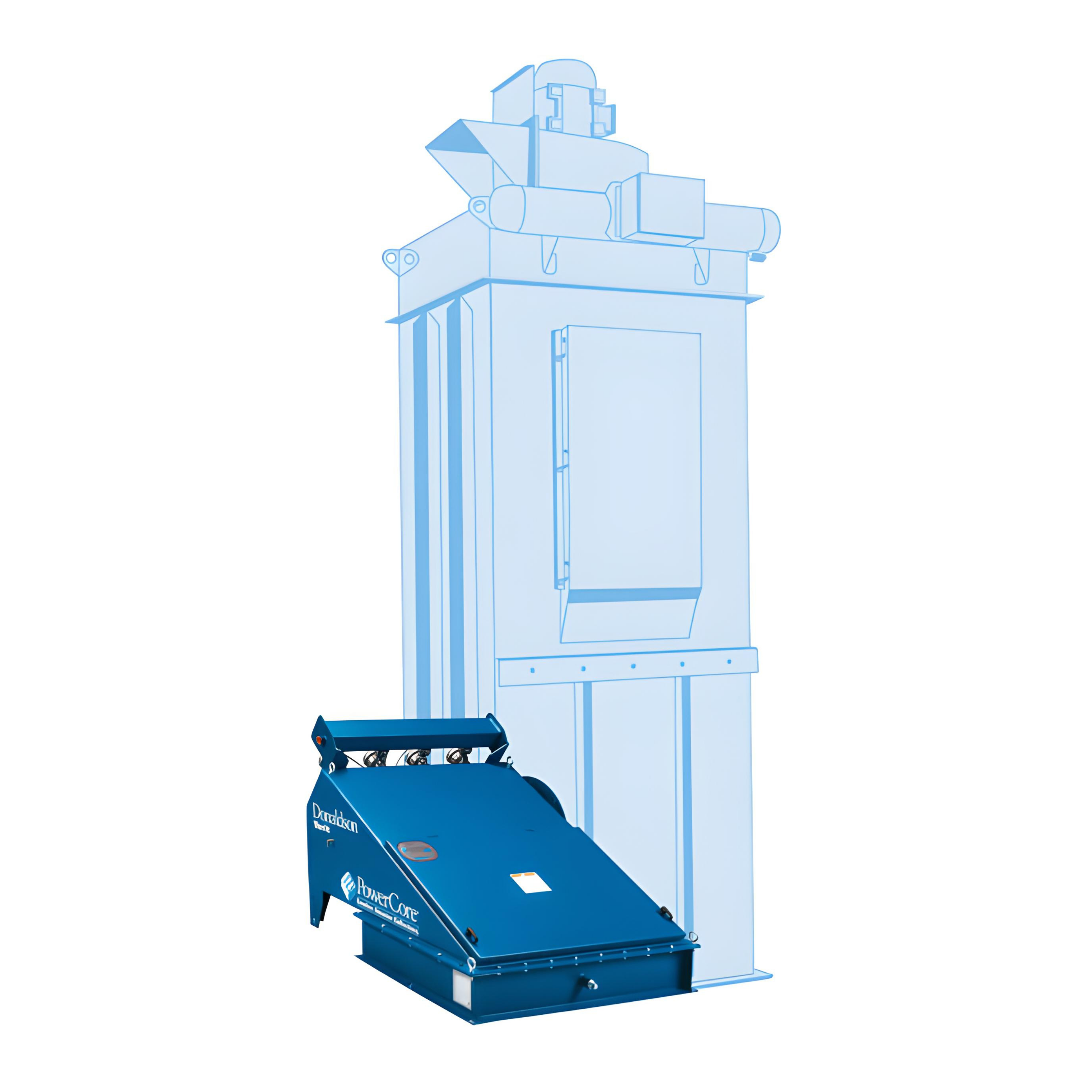

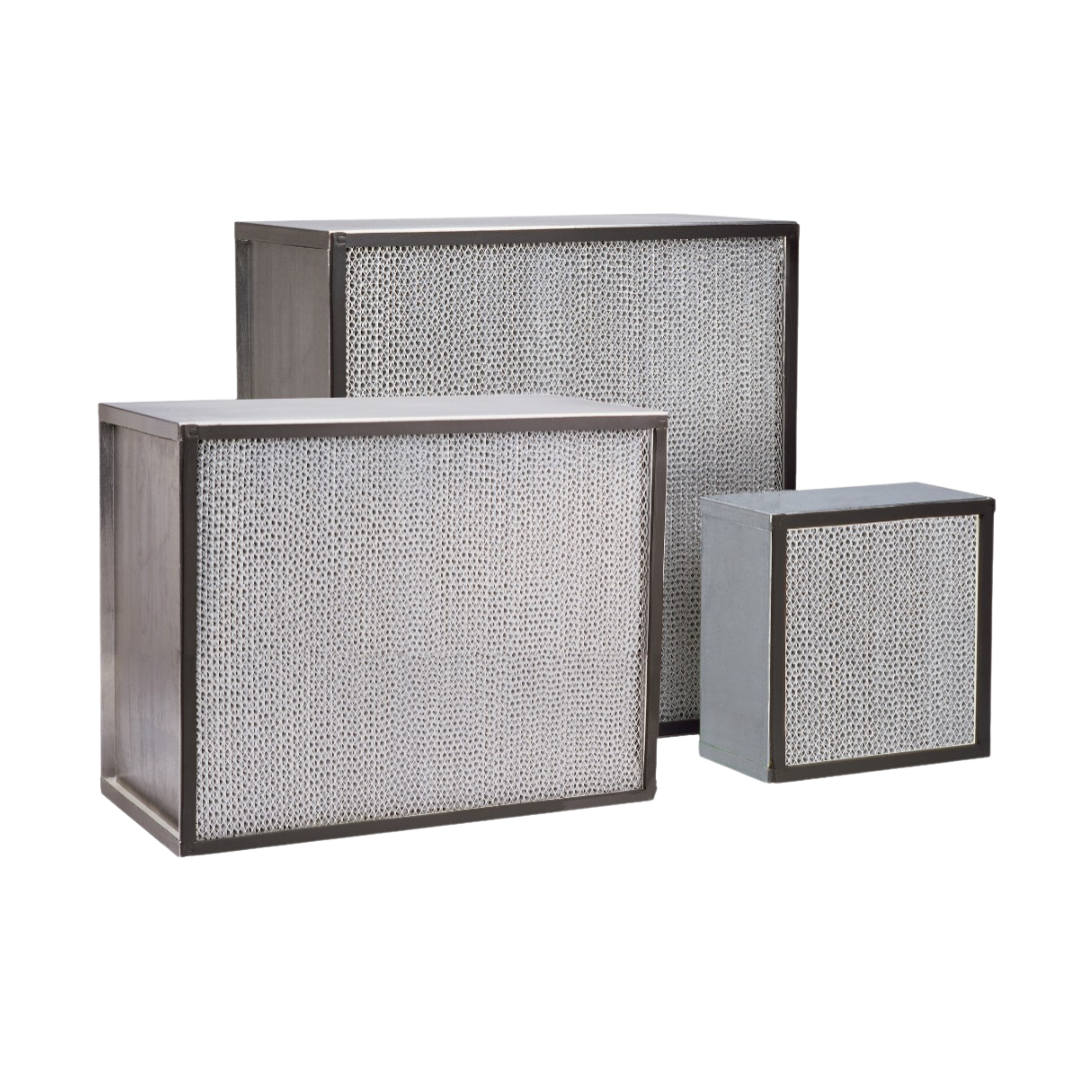

Cartridge Dust Collector, Compact Design and Energy Saving Machine.

If you're after a more compact and energy-efficient system, a cartridge dust collector might be just what you need. This system uses a cylindrical filter (cartridge) that's designed to catch dust particles really effectively. Compared to baghouse types, these tend to be smaller and are great for tight spots.

Cartridge-type dust collectors are great because they can handle dust particles as small as sub-micron size. This makes them perfect for industries like pharmaceuticals or food, where clean air is super important. Plus, these systems tend to be more energy efficient because they don't need as much air pressure to operate.

However, like baghouses, cartridge dust collectors also require regular maintenance. Filters need to be replaced every so often, and the cost can be pretty steep depending on the type of dust you're dealing with. But for us, their efficiency and compact size make cartridges worth considering, especially if you're short on space.

Cyclone Dust Collector, Simple and Durable

Cyclone is a type of dust collector that uses centrifugal force to separate particles from the air. It's a pretty simple system, and since you don't have to replace filters, maintenance costs are low. Cyclone dust collectors are often used as the first stage in a dust control system, especially for handling large particles.

One of the best things about this type is how long it lasts and how strong it is. It doesn't have any parts that can break down, like filters, so it can keep going for a long time without a lot of upkeep. This makes it great for industries like mining or wood processing, where there's a lot of dust that can be pretty rough.

However, this type isn't as good at handling fine particles. It's usually 70-90% efficient, depending on the size of the particles. That's why these systems are often used with other technologies, like baghouses or cartridges, to get better results. For us, a cyclone is a good option if you're looking for a durable and low-maintenance system, but it might not be enough if you need high efficiency for fine particles.

Wet Scrubber, Ideal for Capturing Gases and Particles

Finally, there's the wet scrubber, which is a system that uses liquid (usually water) to capture harmful particles and gases from the air. Wet scrubbers are great for dealing with pollutants like acid gases, ammonia, or dust that gets wet easily. You'll often find these systems in the chemical industry, metal processing, or power plants.

Wet scrubbers are great because they can handle both types of pollutants: particles and gas. This makes them much more versatile than other systems that only focus on particles. Also, since they don't use filters, there are no filter replacement costs to worry about.

But, you should know that wet scrubbers have some downsides. They need a steady stream of water and produce effluent that has to be treated. They can also cost more to operate because they use energy to pump water and treat the effluent. But, for us, wet scrubbers are still a good choice if you need to treat gaseous and particulate pollutants at the same time.

Which One Is Best for You?

The answer depends on what you need. If you need something efficient for fine dust, a baghouse or cartridge might be the best choice. For coarse dust and minimal maintenance, a cyclone is a solid option. Meanwhile, a wet scrubber is suitable if you need to handle gaseous and particulate pollutants at the same time.

Every system has its pros and cons. The key is to figure out what your industry needs and pick the best tech for the job. If you're still feeling unsure, don't hesitate to reach us. We're confident that with this info, you'll make the right call to keep the air quality in your workspace top-notch.

.png)

.png)

.png)

.png)

.png)

.png)