When it comes to keeping compressed air systems dry, it's important to choose an appropriate air dryer. But with all these different options, it can get confusing. Two common choices are the desiccant air dryer and the refrigerated air dryer. They both promise dry air, but their methods are pretty different. So, which one is right for you? It depends on your needs and the special things about each one. Let's take a closer look at these two air dryers and see how they compare!

How Desiccant Air Dryers Keep Things Bone-Dry

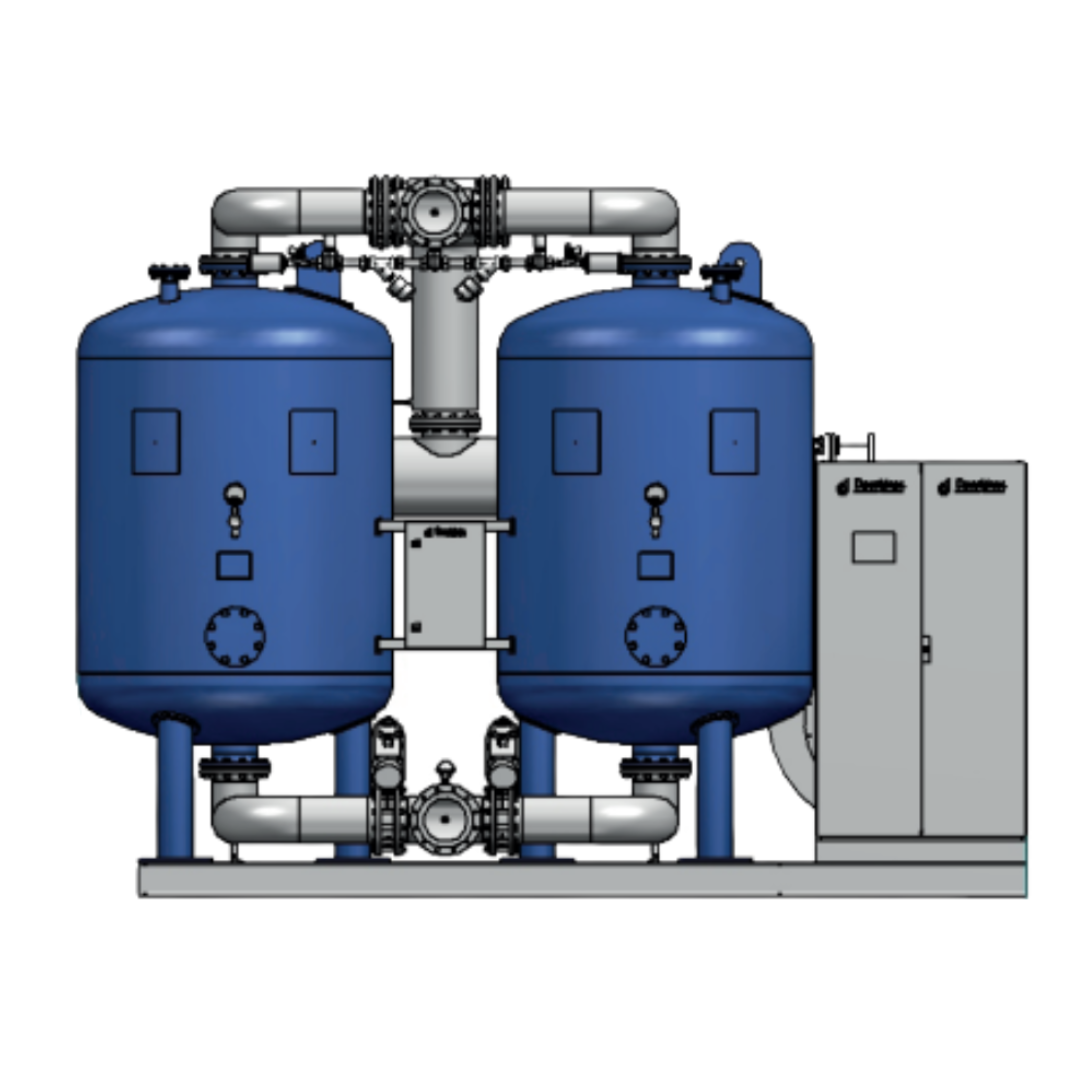

Desiccant air dryers are great for situations where you need super dry air. These dryers use special moisture-absorbing materials (called desiccants) that pull water vapor out of the air as it passes through. It's like those tiny silica gel packets you find in new shoes, but on a much larger scale!

Desiccant dryers can get your compressed air down to a dew point of -40°F or even lower, which is really dry. So if you're running sensitive equipment or dealing with freezing temperatures, a desiccant air dryer could be a great solution. I've seen these dryers work really well in industries like pharmaceuticals and food processing, where moisture can really mess things up.

Here's the thing, though: these dryers often have higher energy costs because of the regeneration process. They need to heat the desiccant to release the collected moisture, which uses up a lot of power. But some newer models are more energy-efficient, so if you want the driest air possible without spending a fortune, it's worth looking into them.

The Cost-Effective and Reliable Refrigerated Air Dryer

If you're looking for a simple, cost-effective way to get moderately dry air, refrigerated air dryers are a great option. These dryers cool the air down, like a fridge, to around 35–50°F, which causes the water vapor to condense. The condensed water is then drained away, leaving you with much drier air. It's not completely dry like the desiccant dryer, but for most applications, it's dry enough.

One of the best things about refrigerated air dryers is how simple and reliable they are. There's no desiccant material to replace or regenerate, which means less maintenance for you. They're great for everyday applications like paint shops or packaging plants, where a little moisture isn't a big deal.

It's also worth noting that refrigerated air dryers aren't designed for sub-zero dew points. If you're operating in a cold climate or you need absolutely dry air, these dryers may not be the ideal choice. However, for many users, they offer an excellent balance between performance and cost.

Weighing the Pros and Cons for Your Business

So, how do you decide between a desiccant air dryer and a refrigerated air dryer? Ultimately, it depends on what you need. If moisture control is a top priority for your business, a desiccant air dryer is a great option. They produce a low dew point, making them perfect for industries where moisture can cause serious problems. Just keep in mind that these dryers often have higher initial costs and energy consumption, so you'll want to make sure you really need that level of dryness.

Another plus is that refrigerated air dryers are a cost-effective way to keep your system mostly moisture-free. They're easy to maintain and deliver just enough dryness for many applications. And we can all use a little savings on energy costs, right?

But don't just take my word for it. The latest industry reports show that refrigerated air dryers are the more popular choice, accounting for around 65% of the market. Why? They're reliable and get the job done for most folks, plain and simple. But desiccant dryers are still the top choice in niche industries like oil and gas, where one wrong move with moisture could spell disaster.

Performance, Costs, and Where Each Dryer Shines

In terms of performance, desiccant and refrigerated air dryers have different strengths. Desiccant dryers are great at providing super dry air with dew points down to -40°F or even -100°F with the right setup. That makes them perfect for situations where even a little moisture could cause corrosion, freezing, or contamination.

On the other hand, you can save money with refrigerated air dryers, which offer dew points of around 35 to 50 degrees Fahrenheit. This is more than enough dryness for general-purpose applications and standard industrial equipment. Another plus is that refrigerated dryers are cheaper to install and maintain, so they're a great choice if you don't need to worry about critical moisture issues.

It's also important to think about how easy it is to look after the system. One of the big differences between refrigerated and desiccant air dryers is how much maintenance they need. With the former, there's no desiccant material to replace, whereas in the latter, you need to keep an eye on the desiccant and replace it regularly. That can end up being quite expensive if you're not on top of it.

Making the Right Choice: Your Specific Needs Matter

The bottom line is that when choosing between a desiccant air dryer and a refrigerated air dryer, it isn't just about which one is better. It's about what works best for you. If your work involves delicate machinery, extreme temperatures, or highly sensitive environments, you'll need a desiccant dryer with ultra-dry air, no question. But if you're more focused on cost-efficiency and need a reliable solution for general applications, a refrigerated dryer is your best bet.

Just imagine it like choosing between a Ferrari and a Toyota. Both will get you where you need to go, but one's built for speed, while the other is all about dependability and value. Once you know what each air dryer does best, you can choose the one that's perfect for your situation.

No matter what you do, whether it's food manufacturing, oil and gas, or just running a machine shop, the right air dryer can make a big difference. Just keep your priorities in mind—like moisture levels, energy costs, and maintenance needs—and you'll be all set.