Ever thought about how air quality affects your workspace? This might not be something that comes to mind often, but there's a device called a dust collector that plays a big part in keeping the air clean, especially in workplaces or industries that produce a lot of dust and smooth particles. Imagine you're working in a dusty environment, like a wood or cement factory, without a dust collector. Over time, you'll notice that every breath you take feels harder due to the microscopic particles present, which can impact lung health.

Dust isn't just about cleanliness. It's also about well-being and efficiency. The National Institute for Occupational Safety and Health (NIOSH) says that if you work with dust for a long time, you're more likely to get a chronic respiratory condition. Dust particles can cause asthma, chronic bronchitis, and silicosis, which are pretty serious and can really affect your quality of life. So, it's important for businesses to make sure their employees work in a safe environment with dust collectors to keep the air quality high and their workers healthy.

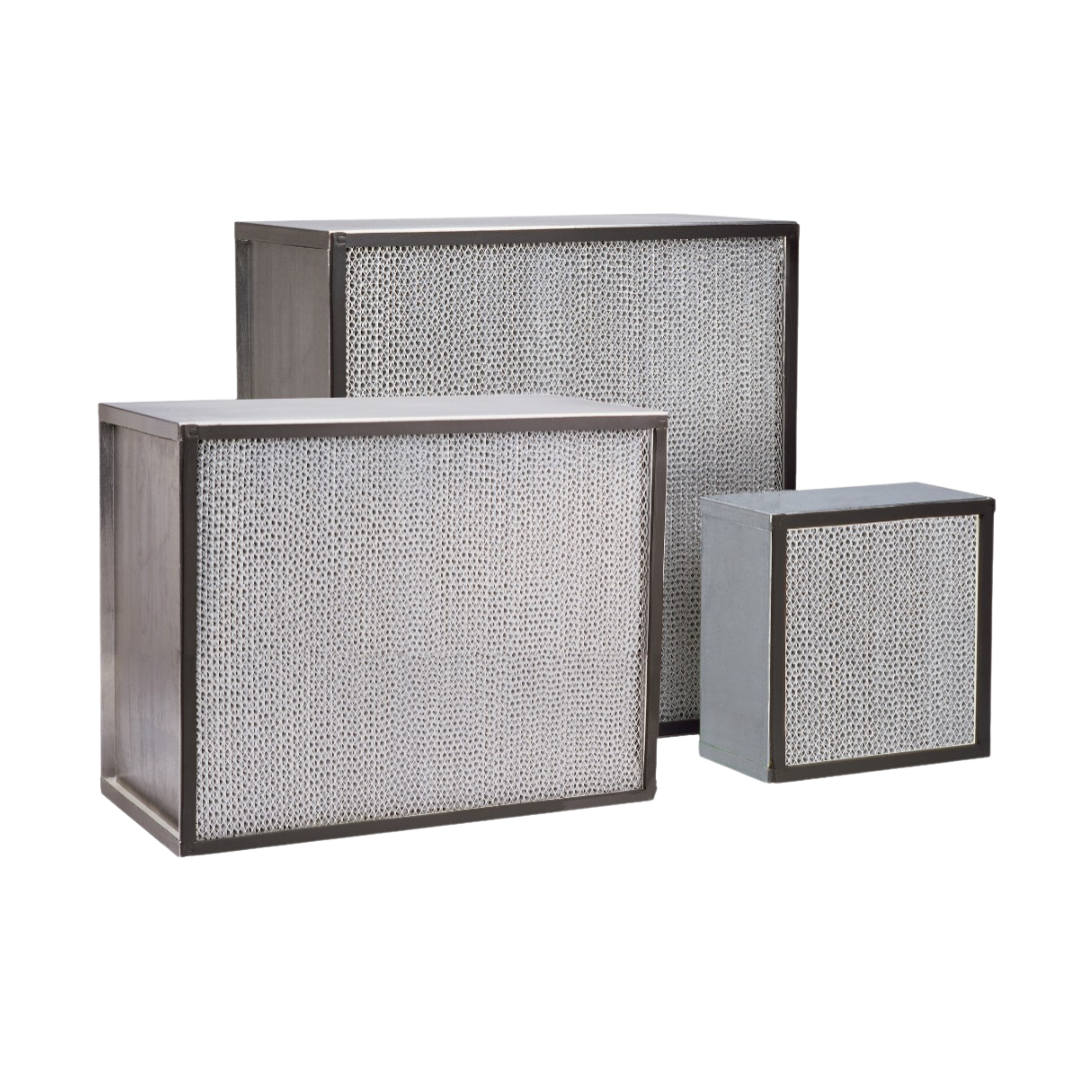

The dust collector acts as a kind of "shadow," constantly cleaning the air of tiny particles and toxic materials. The latest filter tech lets them trap up to 99% of particles in microns, even below 1 micron, so the air workers breathe is pure. You might be surprised to know these machines aren't just used in big factories or industries, but also in small workshops, research labs, and food production areas. Dust collectors are key to protecting employee health and making sure businesses can keep going.

How a Dust Collector Works and Why it Matters

So, what's the real purpose of a dust collector? How does it actually work? Let's take a closer look. The main thing a dust collector does is draw in contaminated air, remove dust and tiny particles that can harm your lungs, and then release purified air back into the workspace. This process starts when the machine draws in contaminated air through a ventilation system connected to the workspace. The contaminated air enters the device and passes through several filtration stages.

It's important to know that most machines use a combination of filters, including pre-filters for large particles and HEPA (High Efficiency Particulate Air) filters designed to trap tiny particles. This filter combo is great for managing wood dust, metal powder, and other industrial pollutants. Dust collectors with the latest tech also have electrostatic filters and smart sensors that keep an eye on airborne dust levels in real time and adjust engine output automatically. This tech makes sure the air is always clean without needing regular manual checks.

You might be wondering what is the big deal is about this tool. Let us give you a quick overview. The Occupational Health Journal found that poor air quality at work can cut worker productivity by as much as 15%. If you don't have the right protective gear, dust can make you tired, give you headaches, and make it harder for you to concentrate. So, what happens when you combine all of this? You get lower productivity and a less supportive work environment. Think about how it feels to have a cough or other breathing problems from breathing in dust for hours. It's not a great feeling, right? It'll definitely make you less excited, relaxed, and focused at work.

Types of Dust Collectors and the Best Choice for Your Needs

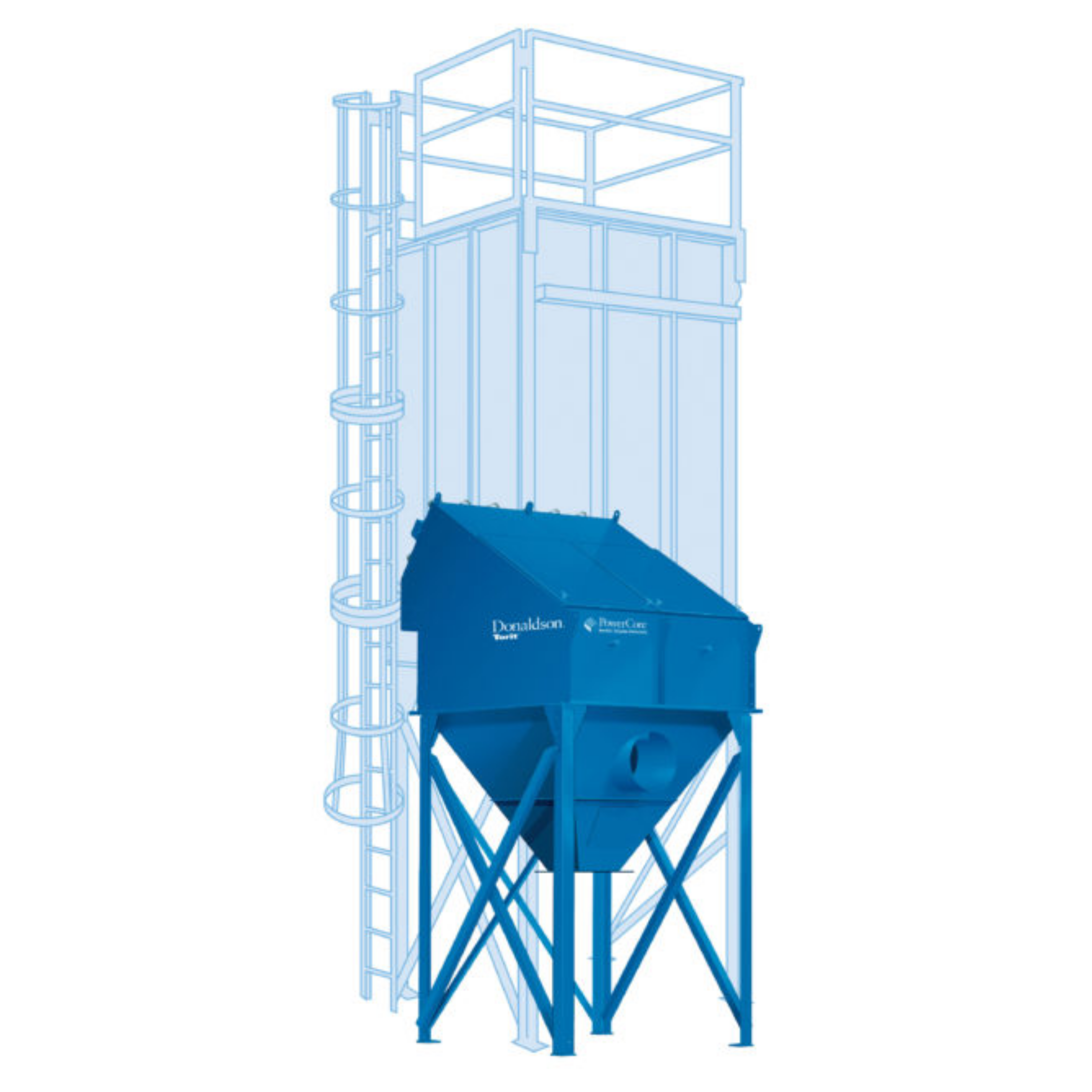

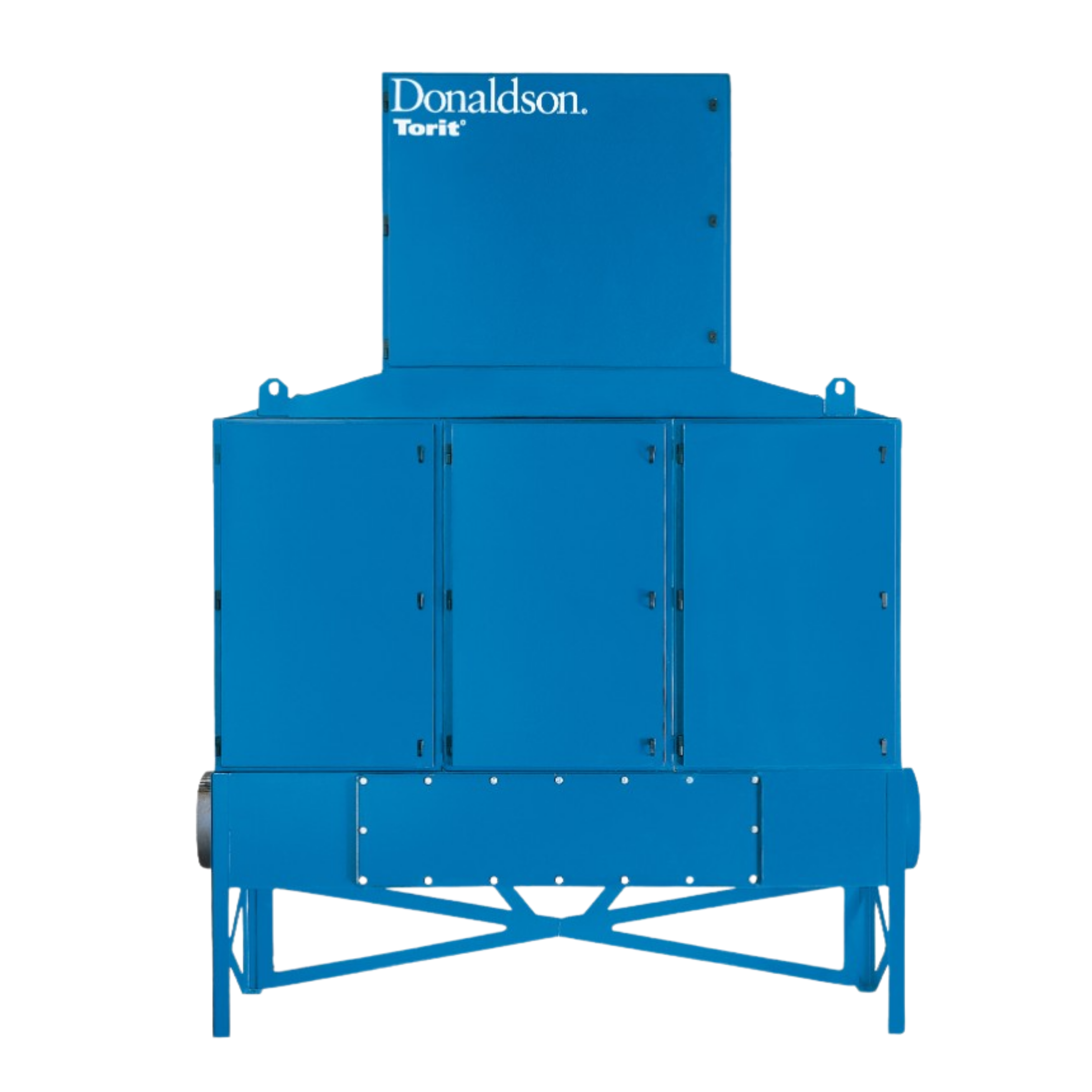

It's important to know that not all dust collectors are made the same way. Each type is designed to do a specific job, so it's important to choose the right one for your needs. One of the most common types is the baghouse collector. This uses an extended fabric sack as a filtering medium. The contaminated air flows into the machine, goes through the bag, and traps the dust particles in the material. The purified air is then expelled into the atmosphere. This is great for managing large amounts of dust and is often used in heavy industries like cement factories, wood processing plants, and metal manufacturing facilities.

Cartridge collectors are also a popular choice because they're compact and can effectively filter smooth particles. Cartridges that can be removed and replaced make it easier to maintain this kind of device. This variety is ideal for compact workshops, labs, and environments with restricted space. It also cleans pretty quickly and can collect dust as small as sub-micron size, making it a feasible and cost-effective choice.

There's another kind of dust collector out there, too. It's called a Cyclone Collector, and it uses centrifugal force to separate larger particles from the air. The heavy particles are pushed against the machine's wall and settle at the bottom, while clean air flows out. While this dust collector isn't as effective at filtering small particles as baghouse or cartridge systems, it's great at managing large amounts of coarse dust, which is common in wood processing, food production, and grain milling.

The technology behind these devices has come a long way. Many of the latest models have automatic sensors that recognize when the filter is almost full and will prompt you to clean and replace it. With this feature, you don't have to keep an eye on the machine all the time. The smart system in these tools ensures optimal performance without worrying about sudden drops in efficiency.

Why Should Companies Invest in the Right Dust Collector?

Picking the right dust collector is a big decision for businesses that want to keep their employees safe and make sure they're as productive as possible. It's not just about following OHS rules, which it should be, but also about making the workplace safer and more pleasant. Studies show that employees in a tidy environment tend to feel safer and more productive. A WHO report says that poor air quality at work can lead to a 30% increase in absenteeism. Unhealthy environments affect employees' performance and health, which can have a negative impact on the company's finances.

Plus, businesses that focus on air quality tend to be more efficient. Machines and workplace equipment last longer if they're protected from dust, which can damage and wear them out early. By buying a dust collector, businesses can cut expensive machinery maintenance costs, make equipment last longer, and reduce the chance of failures.

Many big companies have seen the benefits of using efficient dust collectors. They see big drops in healthcare costs, better operational efficiency, and a more positive image among employees and business partners. If you're looking for the best way to keep your workplace clean and healthy, we at PT Vando Teknik Solusi are here to help. As an official distributor of Donaldson Company, we have a wide range of top-quality dust collectors that are perfect for different industrial sectors. With our experience and commitment to excellent service, we guarantee that each product we offer will improve your business in terms of health, comfort, and profitability.

.png)

.png)

.png)

.png)

.png)

.png)