Have you heard of or know about air dryers? They might seem like a tool only for factories or large industries, but did you know that air dryers are also commonly used in daily life? In this article, we'll look closely at how an air dryer works, its advantages, and the different kinds of air dryers available. This will help you understand them better and might be the perfect solution for the humidity issues you often face!

What is Air Dryer?

Before we dive into how an air dryer works, let's take a quick look at what they are and how they're used. Simply put, an air dryer is a tool that gets rid of moisture or water vapor in the air. This air dryer is really important for keeping the air quality up in industry, including in pneumatic systems, machinery, and the food storage process. If one of your machines comes into contact with humid air, it's likely that your machine will start to perform poorly and possibly damage its internal parts.

Even though air dryers are most often found in big factories and manufacturing plants, they can be used at home too. They work in a similar way to the air dryers in refrigerators and air conditioning units, keeping the air clean and dry so you can breathe easily.

Removing Moisture with Advanced Technology

Now, let's talk about how this air dryer works. Simply put, an air dryer gets rid of moisture in the air. We usually breathe in moisture in the form of water vapor, especially in places with high humidity. When air goes into the dryer, the vapor turns into liquid. Usually, this involves cooling the air, or what we call adsorption, which removes humidity from the air.

There are two main types of air dryers: refrigerant and desiccant. They work in different ways, but they all have the same goal: to remove moisture from the air.

- Refrigerant Air Dryer

Refrigerant-type air dryers work by cooling the air that goes into the device. The cold air makes the water vapor in the air turn into liquid. This is similar to how air conditioners in homes work, where moisture in the air turns into water and exits. This type of air dryer is used a lot in different industries because it's very efficient and has low operating costs.

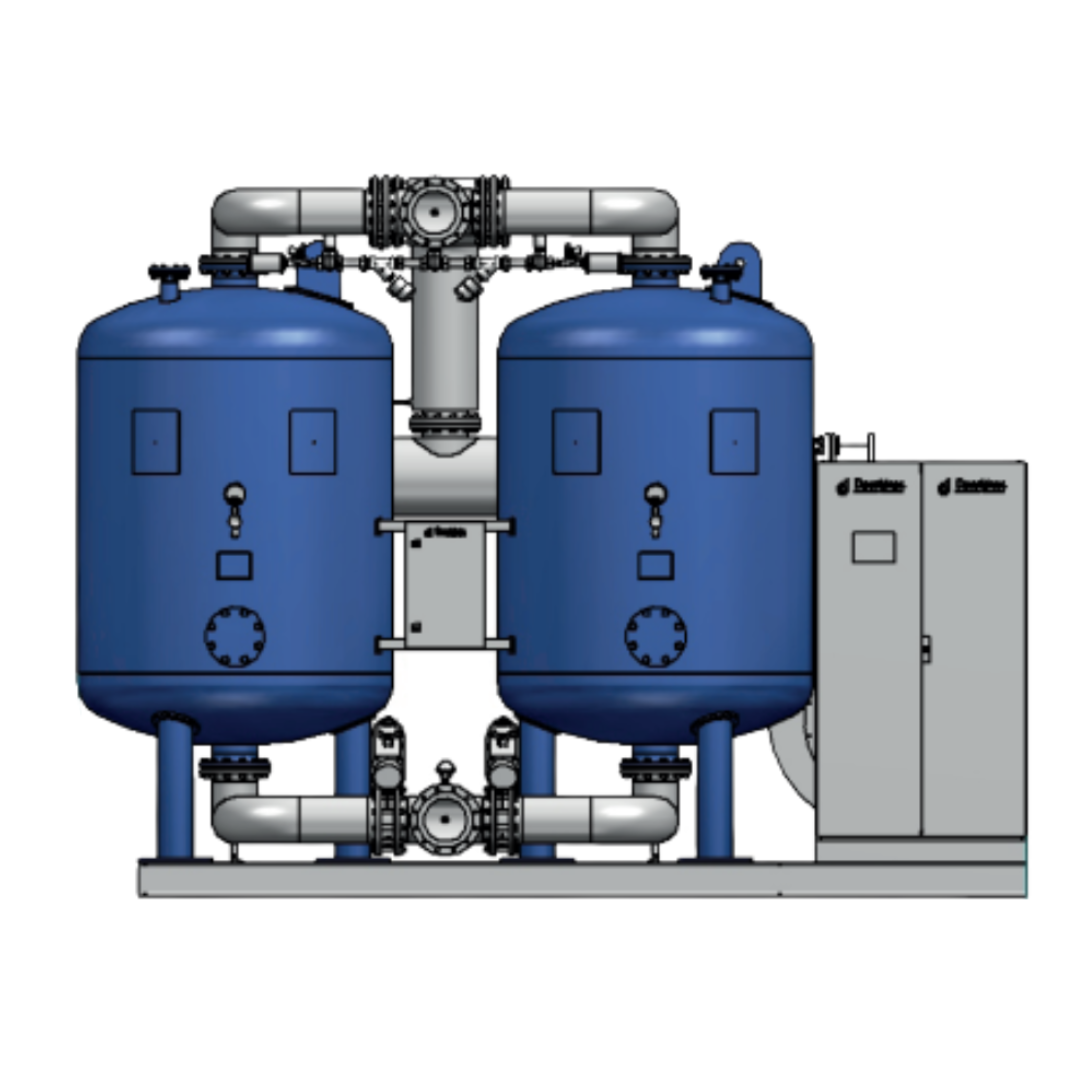

2. Desiccant Air Dryer

Desiccant air dryers use absorbent materials like silica gel or zeolite to trap the water vapor in the air. As soon as the air enters the air dryer, the humid air goes through a long process with the moisture-absorbing substance, which then captures and retains the moisture in the air. This type is often used in sectors that need air with extremely low humidity, including pharmaceuticals, medicine, electronics, and the food and beverage sector.

Why Air Dryer is Important?

You might be wondering if this tool is really important to the industry. The answer is a big yes! For example, in manufacturing or processing, pneumatic systems that use compressed air can be damaged if the air has a lot of moisture in it. So, using an air dryer makes sure that the air going into the system or equipment stays dry and is high-quality.

Another benefit of using an air dryer is that it can help make things more efficient. For instance, a refrigerant-type air dryer keeps the air temperature steady during cooling. This dry, consistent air can improve engine performance and prevent corrosion that could damage internal engine parts.

It's true that air dryers can cut equipment maintenance costs by as much as 30% in some industries, according to the Compressed Air and Gas Institute (CAGI). So, using an air dryer not only stops equipment from breaking down but also helps cut operational costs.

Types of Air Dryer You Need to Know

There are lots of different air dryers on the market, and the best one for you depends on what you need it for. Here are some of the main types of air dryers:

- Cycling Refrigerated Air Dryer

This kind of air dryer uses a compressor to control the temperature and moisture levels of the air. As the air temperature drops, the water vapor condenses and is removed. It's a good choice for sectors that don't need elevated air pressure.

2. Non-Cycling Refrigerated Air Dryer

This type of air dryer is different from the cycling type because it keeps working to maintain a consistent air temperature all day long. It's great for sectors that need dry and consistent air quality.

3. Membrane Air Dryer

This type of air dryer uses membrane technology to separate water vapor from the air. It's a more energy-efficient choice because the filtration process uses very little electrical energy.

4. Desiccant Air Dryer

As explained earlier, desiccant air dryers use substances like silica gel or zeolite to absorb moisture. This type is often used in places that need very dry air, like the pharmaceutical, electronics, and FnB industries.

When to Use an Air Dryer?

If you work in an environment that requires dry, humidity-free air, an air dryer is the best solution. In industry, they're used to keep compressed air systems running smoothly, like pneumatic machinery and processing tools. And in your everyday life, an air dryer can help keep indoor air quality high and comfortable, without excess moisture.

Once you know how an air dryer works and what it can do for you, you can choose one that's right for your needs. So, are you ready to start using an air dryer, either at work or at home?

The Importance of Air Dryer Maintenance

Air dryers are super important, but remember that they need some TLC too. If you're using one in an industrial setting or manufacturing plant, it's a good idea to give it a regular check-up. Usually, the desiccant in the air dryer needs replacing or recharging, which keeps it working well and prolongs its life.

On the other hand, if you don't take care of your air dryers, the system won't work as well. This could even lead to bigger problems like leaks or breakdowns. So, don't forget to take care of your air dryers!