Dust collectors are super important in the food industry. They make sure everything's safe and clean during production. No matter what you're doing in the food industry, from roasting coffee beans to grinding spices to managing a big processing line, controlling dust is essential for maintaining high standards. Dust in food processing areas affects the quality of the product and also poses serious health and safety risks, like food contamination or even explosions due to combustible particles. That's why having a reliable dust collector is not just a smart move, it's a necessity.

Why Dust Collectors Are Essential in Food Processing

First of all, dust collectors help keep the air clean in processing facilities. Food particles, like flour, sugar, or spices, often become airborne during production, and these particles can cause respiratory issues if not controlled properly. Effective dust collectors filter out these particles, so employees can breathe safe, clean air while they work. This is especially important in facilities where allergens like wheat or nuts are processed, because airborne particles could contaminate allergen-free products if not managed correctly.

On top of that, dust collectors are key in preventing fire hazards. Think about it—finely powdered substances, like grain dust, are highly combustible. Without the right system to capture and remove these particles from the air, the risk of explosions goes way up. In fact, studies have shown that dust explosions are a big concern in food facilities, which is why it's so important to have proper dust management systems in place to reduce risks and keep everyone safe.

How Dust Collectors Improve Efficiency and Compliance

In food production, keeping things clean isn't just about making the workspace look nice; it's the law. Food safety regulations, like those from the FDA, require facilities to control airborne particles to prevent contamination. Dust collectors help meet these standards by capturing and filtering particles before they can settle on surfaces or products. This keeps the production area compliant with hygiene standards, reducing the risk of costly recalls or shutdowns.

Plus, dust collectors make things run more smoothly. By getting rid of dust, they keep equipment from getting clogged or malfunctioning because of particles. This makes machinery last longer and saves time and money by reducing downtime. Modern dust collectors have features like automated controls and real-time monitoring, which makes it easier for facilities to manage and optimize their dust control processes effectively.

What Types of Dust Collectors Are Used in the Food Industry?

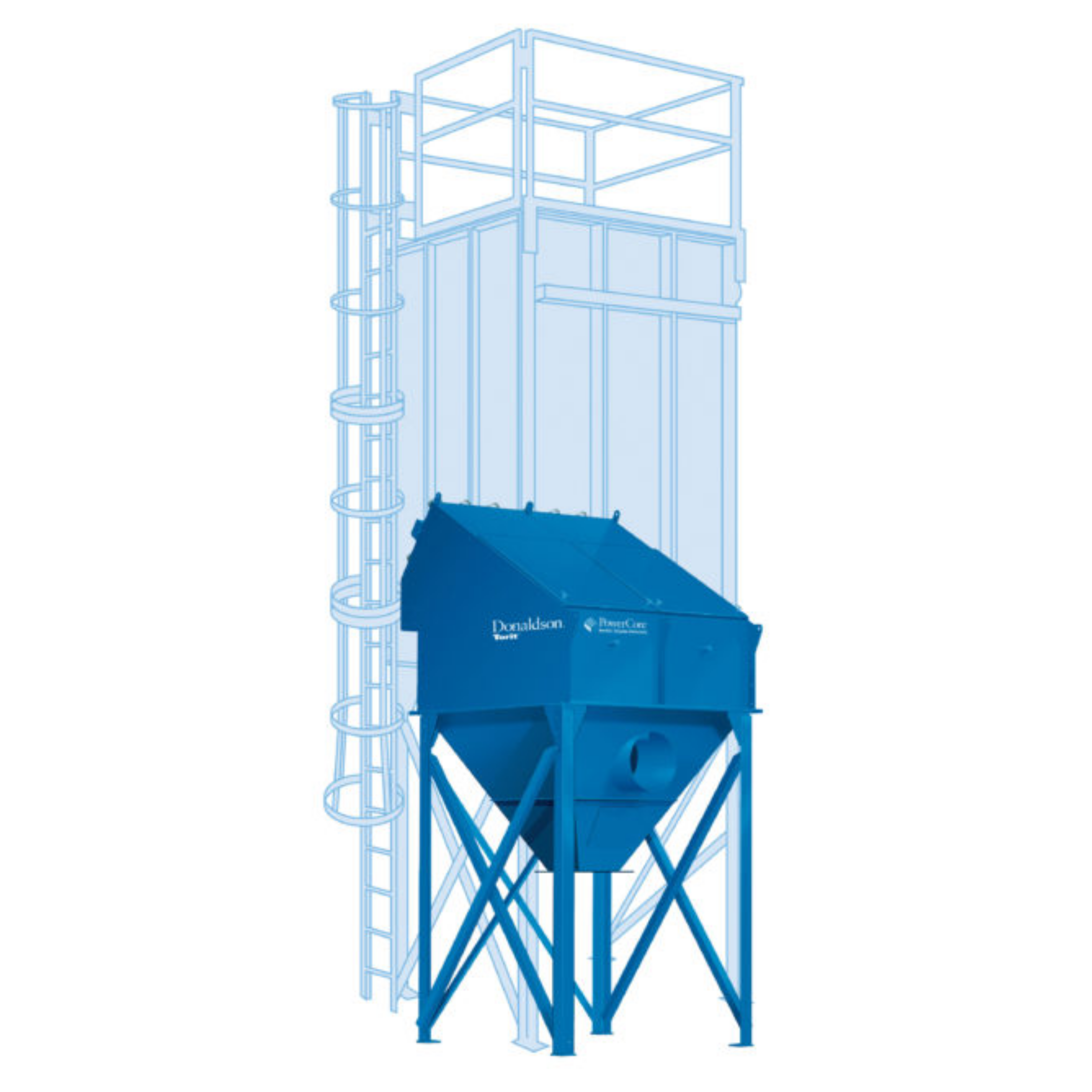

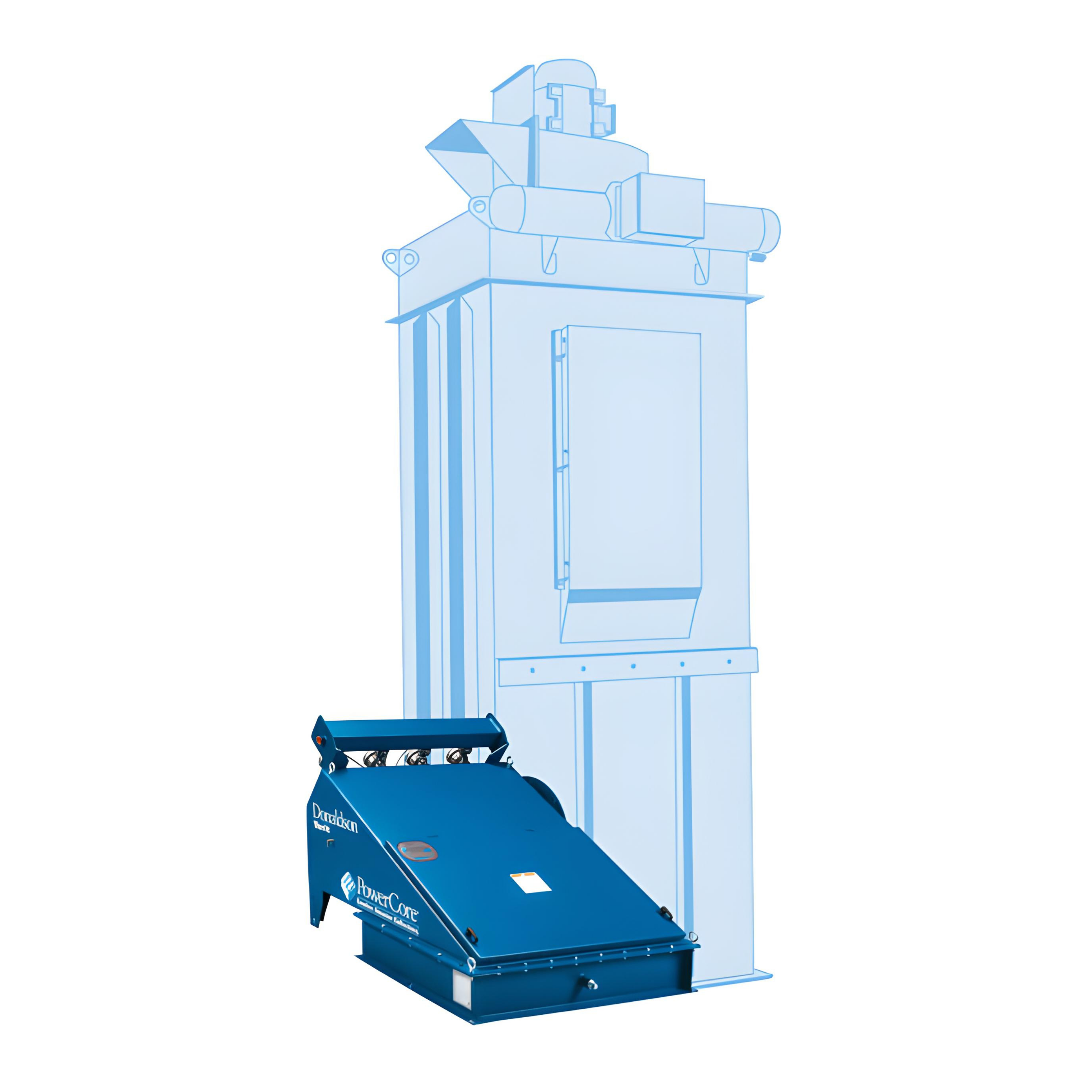

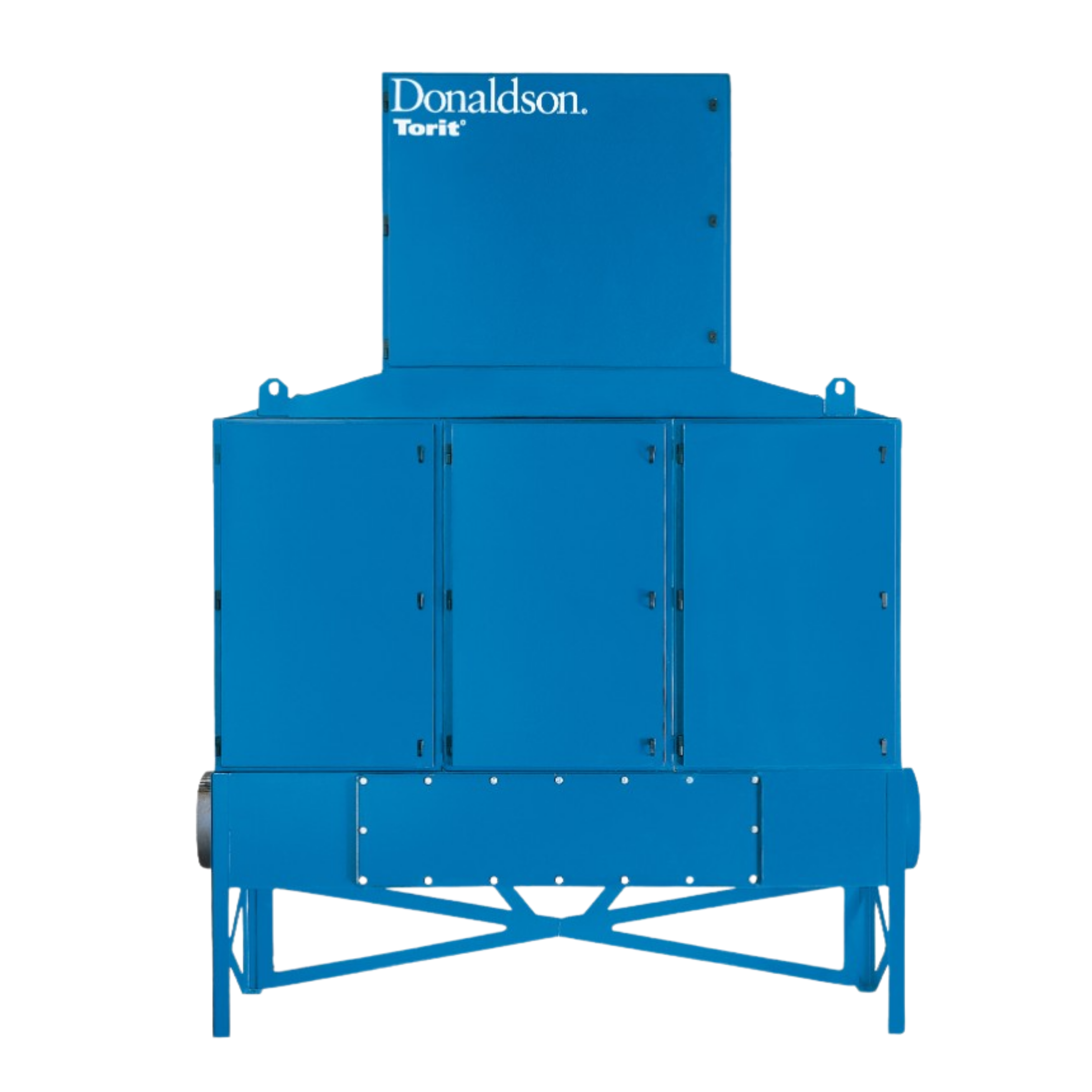

Different processes need different types of dust collectors. For instance, baghouse dust collectors are a popular choice in many facilities because they can filter out fine particles really efficiently. Cyclone collectors are another option, which use centrifugal force to separate dust from the air. Both types are widely used because they're effective for handling the high dust loads common in food processing. In more specialized scenarios, wet scrubbers or mist collectors are used to manage moisture-laden dust, often found in processes involving steam or other liquids.

The right dust collector depends on what you need for your operation. If you're dealing with combustible dust, for instance, you'll want to look for systems with explosion protection features, like explosion venting or isolation systems. With the right setup, you can make your production line safer and more efficient, and get a cleaner, safer product for consumers.

It's really important to make sure you have the right dust control measures in place to keep your food safe and your operations running smoothly. Investing in the right technology will help you protect your workers, stay compliant, and keep your production lines up and running.

.png)

.png)

.png)

.png)

.png)

.png)