.png)

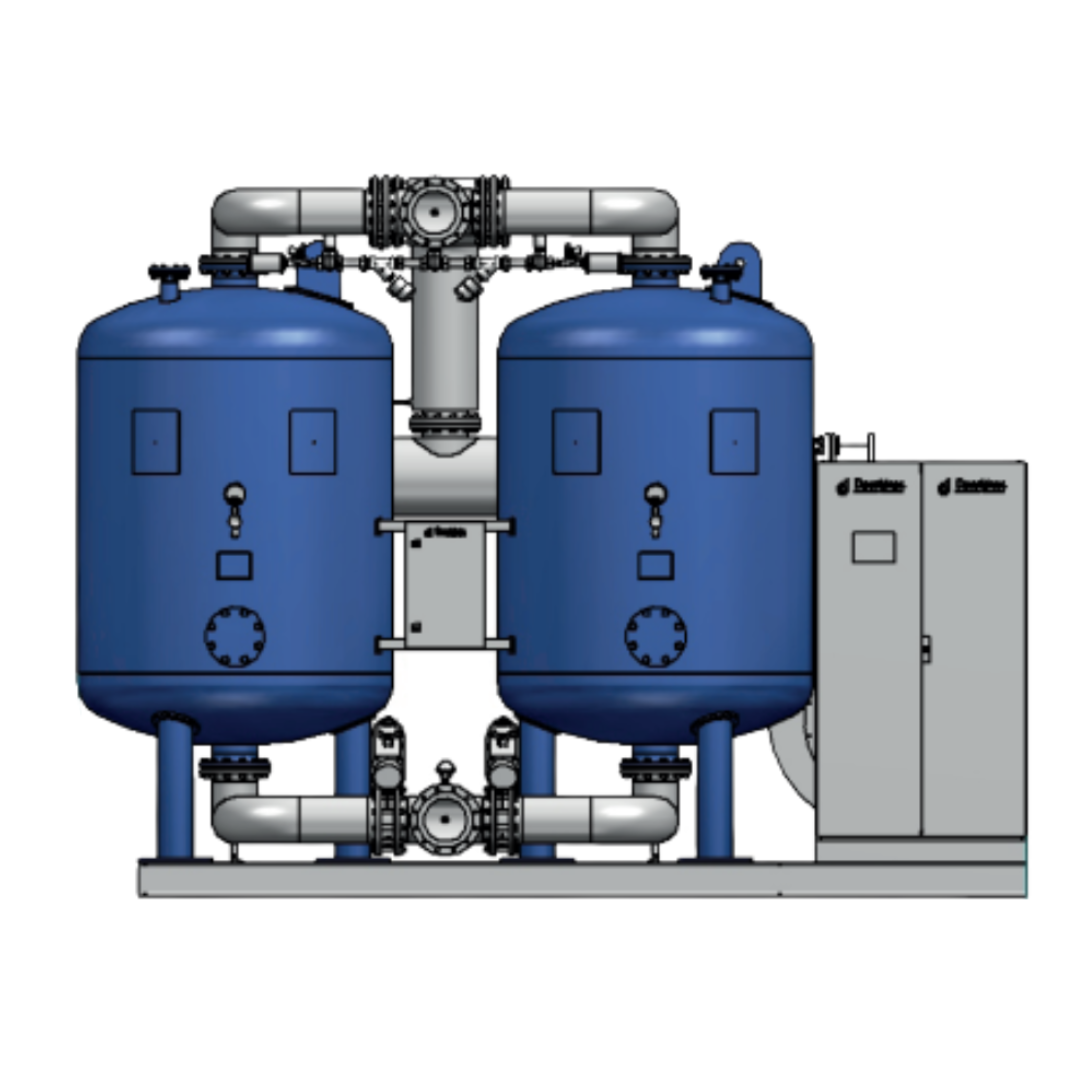

HRE Adsorption Dryer

As with all externally heated adsorption dryers, the desorption of adsorbed moisture in the HRE model dryer occurs by heated blower airflow. Desiccant cooling is carried out by a partial flow of dry compressed air. Since the cooling process is independent of ambient conditions, the HRE model can be used worldwide. or variations. The standard program covers system sizes of 375 m³/h to 13,600 m³/h for pressure dew point down to -70 °C.

HRE operating principle

The HRE 0375-13600 external heat regeneration adsorption dryer works according to the principle of dynamic adsorption. Wet compressed air flows through the dryer bed. As it flows, water vapor is pulled out of the compressed air. Because the adsorption capacity of the dryer is limited, the flow direction must be changed before the dryer is completely saturated. Using two parallel adsorption vessels (adsorber AD1 + AD2) with

reciprocating function, a permanent supply of dry air to consumers is guaranteed. One adsorber is always available to dry the compressed air. The second absorber is regenerated at the same time. The activation time successively the regeneration time is always shorter

from the loading time of the working adsorber. Regeneration of saturated dryers is realized in two steps:

1. Desorption in reverse flow to adsorption direction with externally heated blower air

2. Cooling of the heated desiccant with a partial stream of dry compressed air

.png)

.png)

.png)

.png)

.png)

.png)