We usually think of air pollution as obvious stuff like vehicle fumes or factory waste, but there's a hidden threat that's even more dangerous and often overlooked: industrial dust. These tiny particles may be invisible to the naked eye, but they can damage your health, the environment, and even hurt business profits. The good news is that this threat can be controlled with simple technology, such as dust collectors and filtration systems. These "heroes" are the ones that keep the air clean in the work environment.

Respiratory and Environmental Impacts of Industrial Dust that You Should Never Ignore

Industrial dust isn't just dirt on the floor or machinery. It can contain micro-particles like silica, heavy metals, and wood fibers. When you breathe in these particles, they can get stuck in your lungs and cause chronic respiratory diseases like asthma and cancer. According to data from the WHO in 2023, 15% of lung disorder cases worldwide are related to exposure to industrial dust. It's pretty amazing to think that employees can breathe in thousands of these harmful particles during just one workday without even realizing it.

It's not just people who are affected; the environment around the factory is also impacted. Flying dust can pollute the soil and water, disrupt ecosystems, and even damage production machinery. For example, a wood processing plant can lose 20% of machine efficiency due to dust buildup. And we can't forget the risk of fire because certain particles are flammable. This shows that industrial dust is a serious problem.

Unfortunately, a lot of companies still don't realize how big a risk this is. They're putting their employees at risk, and they might also get fined for breaking the rules of K3 (Occupational Safety and Health). According to the Indonesian Ministry of Labour (2023), there was a 30% jump in dust limit violations in Indonesia since 2021. That's when dust collectors become a must for responsible industries.

How a Dust Collector Works that's More than Just a Dust Filter

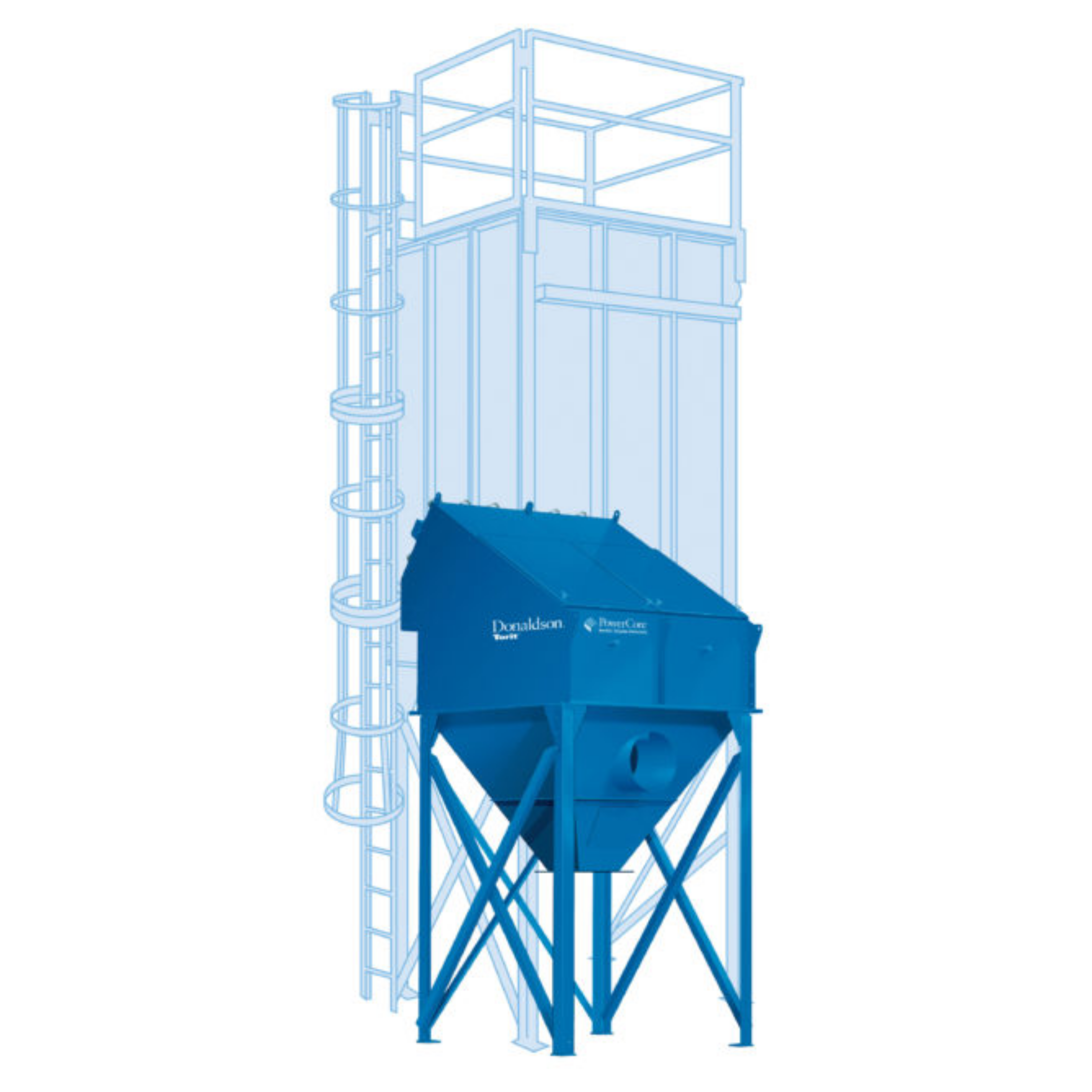

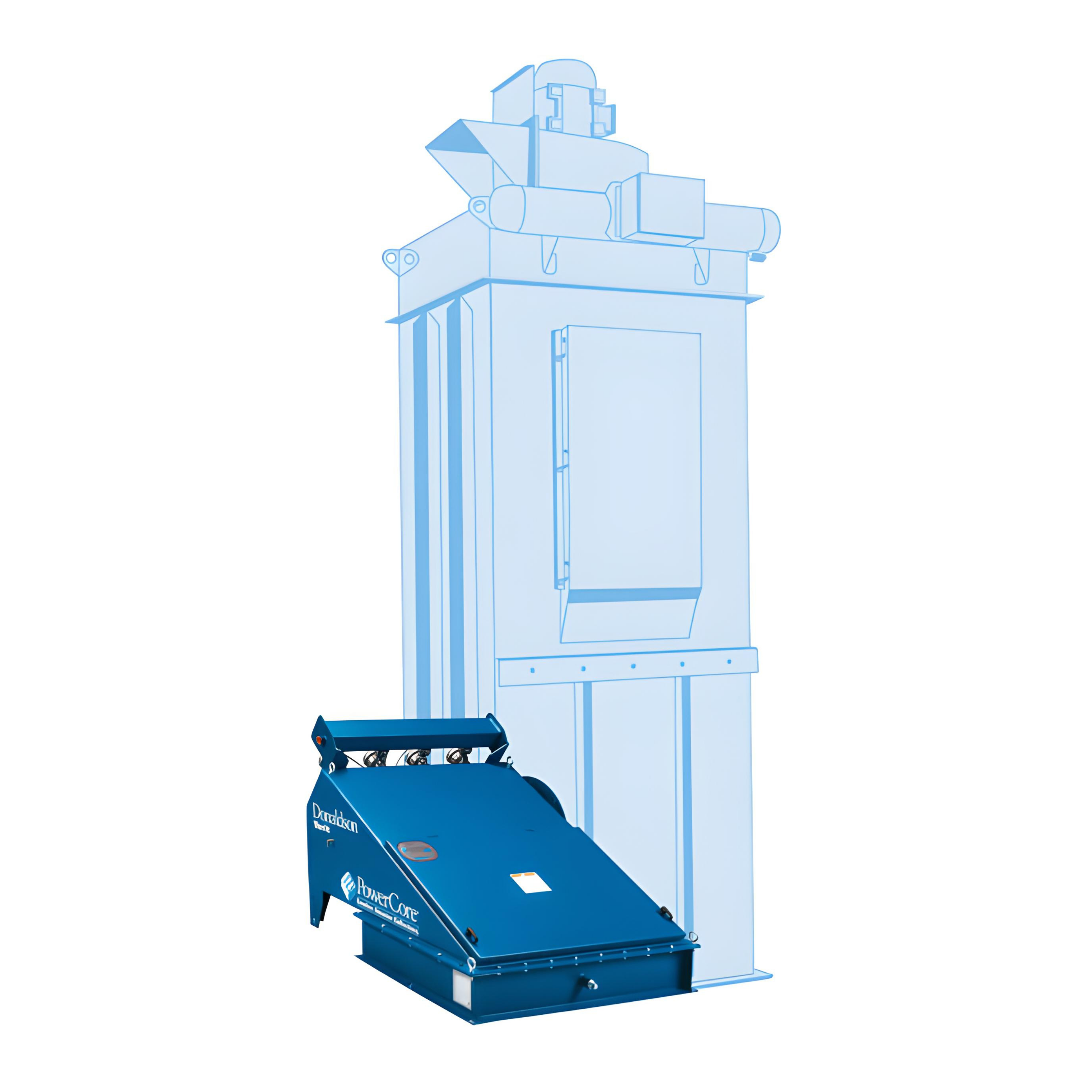

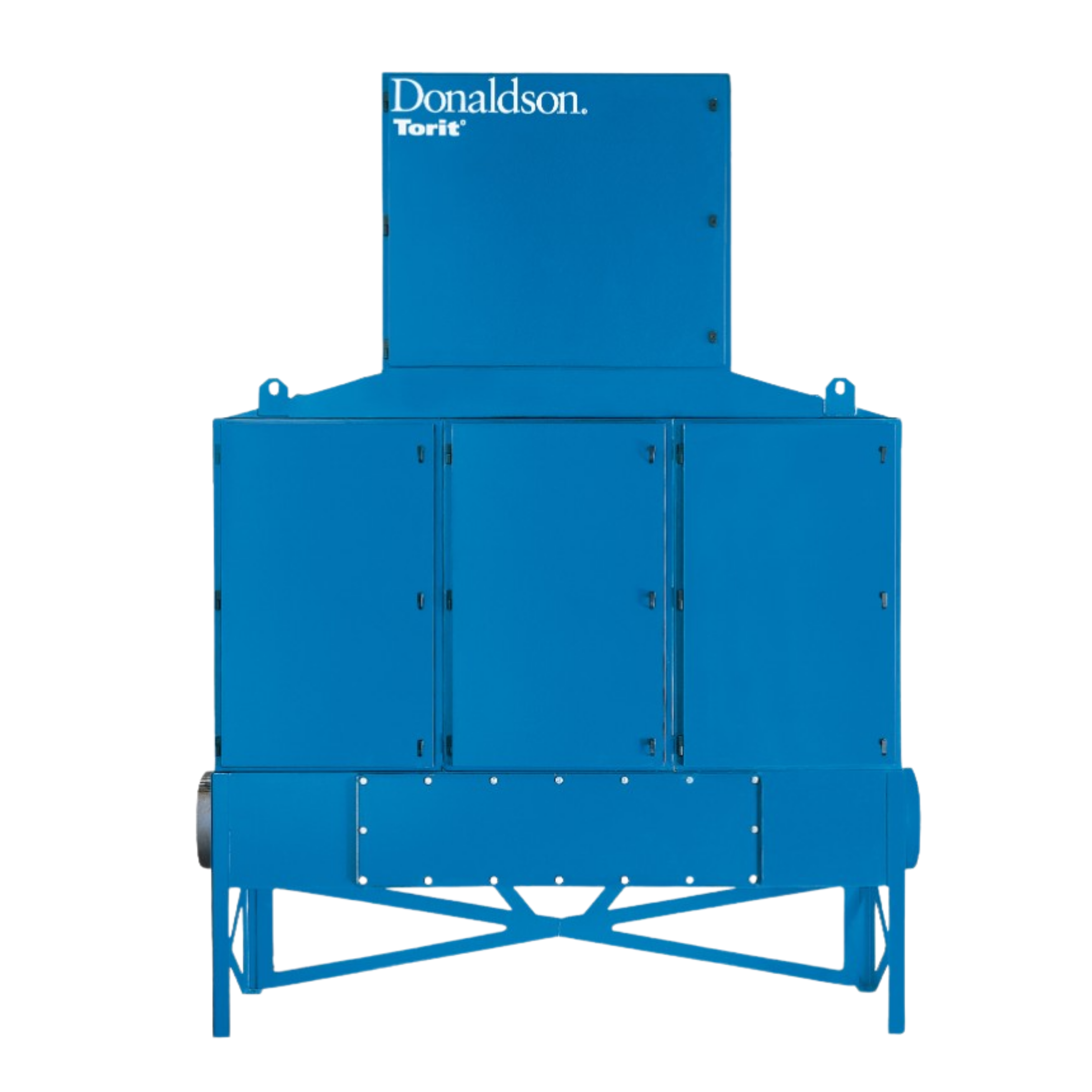

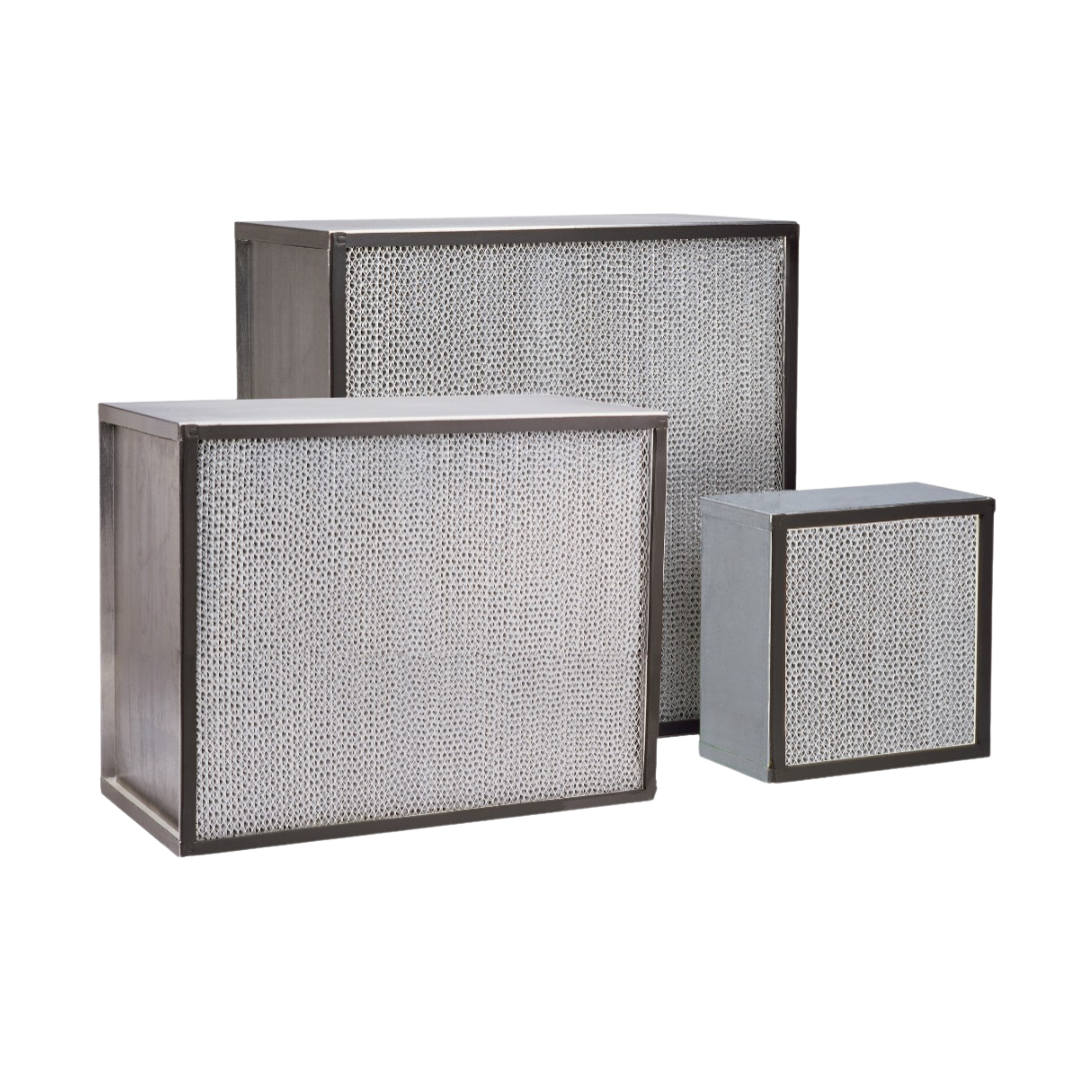

If you think of a dust collector as just a giant vacuum cleaner, you're missing out. These systems are designed with advanced technologies such as HEPA filters, particle separation cyclones, or electrostatic precipitators that can trap 99.9% of particles measuring 0.3 microns—smaller than a human hair! The principle works like a kidney: filtering out "toxins" from dirty air and then returning clean air to the environment.

There are a lot of benefits to using dust collectors in factories. According to the Journal of Industrial Safety study (2024), these collectors can reduce machine maintenance costs by up to 40%. Clean air also makes employees more focused and productive because they don't have to worry about coughing or eye irritation. Imagine working in a room with air as clean as the mountains—this filtration system can make that a reality.

Dust collectors are great for helping companies meet environmental regulations. They can reduce harmful particle emissions by up to 95%, which helps companies avoid sanctions and build a positive image in the eyes of the public. It's an investment that's good for both lives and business reputation.

Environmentally Friendly Dust Collector Innovation in the Era of Advanced Technology

Dust collectors aren't as outdated as you might think. In the digital age, these systems have IoT (Internet of Things) to keep an eye on air quality and save energy. Some factories in East Java have even saved up to 25% on electricity by using smart sensor-based dust collectors.

Modern filters are also becoming more eco-friendly. A lot of them can be washed or recycled, which reduces the amount of solid waste that would otherwise be a problem. For example, the latest nanofiber filters trap ultra-fine particles without messing up the airflow. So, efficiency and sustainability can go hand in hand.

If you've got a small industry, don't sweat the high costs. Lots of vendors are offering modular systems these days, so you can find one that fits your budget and production scale. Just do your research and pick the technology that's right for you. There's no reason to wait when it comes to getting a dust collector installed.

Easy Steps to Deal with Industrial Dust in the Workplace

The most common question we get is, "How do I choose the right dust collector?" The answer depends on the type of dust, the industry scale, and the budget. For example, the wood industry is suitable for a cyclone system, while chemical factories need corrosive-resistant filters. Don't just buy it—consult an OHS expert or a professional filtration service provider first.

After you install it, it's important to keep up with regular maintenance. If your filters are clogged or your systems aren't cleaned often, they can start to pollute the place. The Indonesian Pollution Control Association says that 50% of dust collector failures are due to incorrect maintenance. So, make sure your team has a clear and measurable maintenance schedule!

Finally, make sure your employees know how important it is to have clean air. Encourage them to help keep the work area clean and let you know if anything goes wrong with the system. If everyone works together, we can control the threat of industrial dust without losing productivity.

Industrial dust may be invisible, but its impact is real. With dust collectors, we're protecting ourselves, the environment, and building a healthy and sustainable industry. Clean air is everyone's right, so let's start caring before it's too late!

.png)

.png)

.png)

.png)

.png)

.png)