When we talk about compressed air systems, it's important to keep the air quality up. One way to make sure the air stays clean and dry is by using an air dryer. There are two main types of air dryers: refrigerated dryers and desiccant dryers. Each has its own pros and cons, so you'll want to think about what you need before making a choice.

Pros and Cons of Refrigerated Dryer

Refrigerated dryers work on a simple yet effective principle. Basically, compressed air is cooled to a certain temperature, usually between 2°C and 10°C. This cooling process causes the water vapor in the air to turn into a liquid. Then, the liquid is separated and disposed of, and the dried air is reheated to room temperature before use.

Refrigerated dryers are great because they don't cost an arm and a leg to run. They're perfect for all sorts of industrial uses that need dry air but don't require super high levels of dryness. For example, in workshops or manufacturing plants, they work well and don't cost an arm and a leg. Plus, thanks to modern technology, they use eco-friendly refrigerant gases, which is good for the environment.

But remember, refrigerated dryers have their limits on the dew point they can reach. Usually, the dew point can only be reached around 3°C, which is good enough for most industrial applications, but might not be enough for places where moisture sensitivity is a big deal. Also, its efficiency might drop if the ambient temperature is too low, since its cooling system is designed to work at a certain temperature.

Pros and Cons of Desiccant Dryer

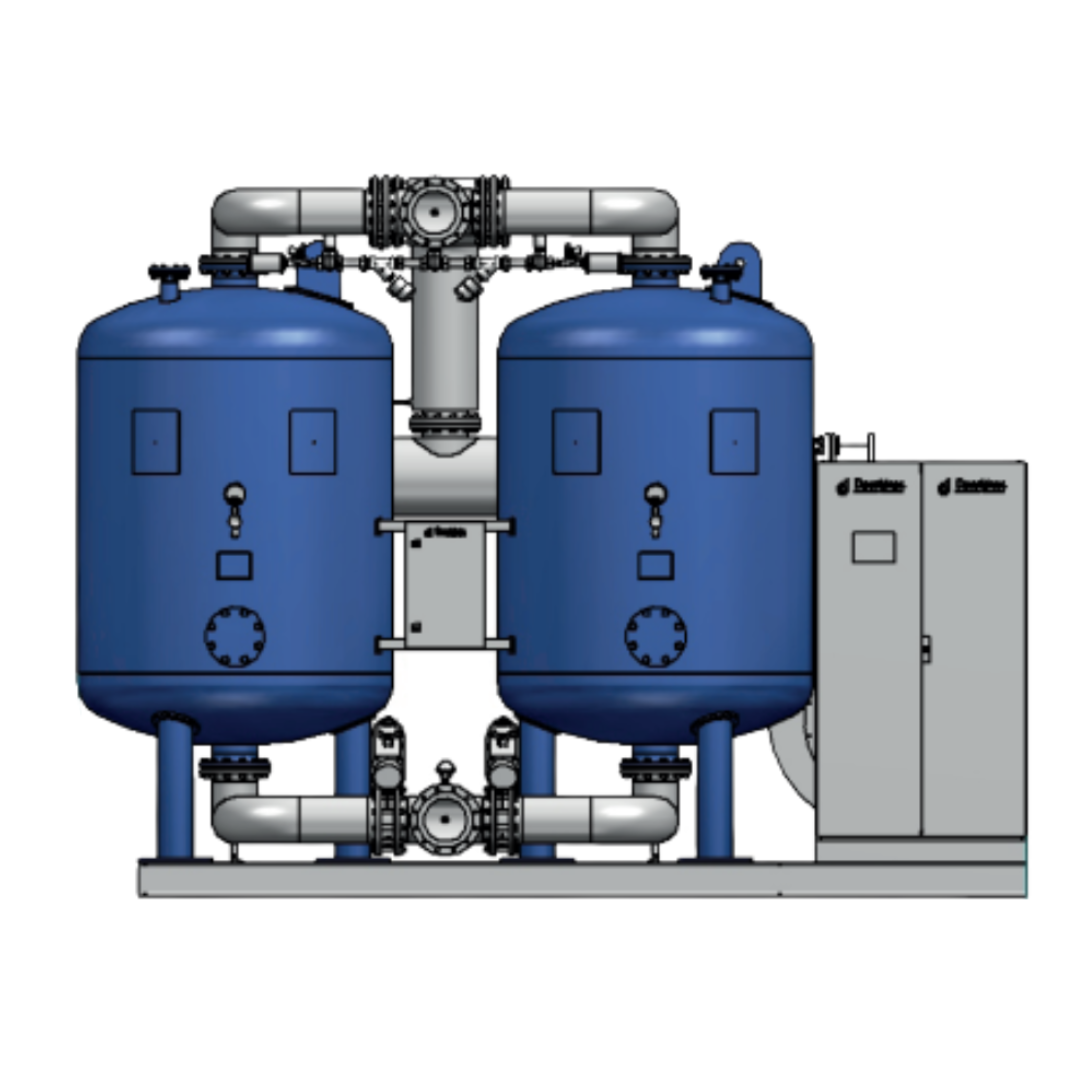

Desiccant dryers work by using special materials like silica gel, activated alumina, or zeolite molecules to soak up moisture from compressed air. The air goes through this material, which attracts and captures moisture really well. The end result? Extremely dry air, with dew points that can drop to -40°C to -70°C, depending on the design and operating conditions.

The best part about desiccant dryers is that they can really dry out the air, which is crucial for a lot of important industries like pharmaceuticals, electronics, and food and drinks, since even a little bit of water in the air can mess up the product. They're also great for places with extreme temperatures, since they don't need refrigeration to get rid of moisture.

But desiccant dryers use more energy than refrigerated dryers. The regeneration process of the desiccant material often needs more airflow or heating, which can raise operational costs. Maintenance is also more intensive, as the desiccant must be replaced or regenerated periodically to ensure optimal performance. Additionally, desiccant dryers are usually larger, requiring more installation space.

Choosing the Right Air Dryer

Depending on your specific needs and operating conditions, you might want to go with a refrigerated dryer or a desiccant dryer. If you need air that's moderately dry and you're looking to save some cash, a refrigerated dryer is probably your best bet. You can use it for all sorts of things, like pneumatic systems, workshop tools, and other light industrial applications.

But if you need really dry air, like in a sterile room or for food production, a desiccant dryer is better. It's more expensive, but it can get rid of moisture really well, so it's essential in some cases.Also, think about how much energy it uses, how much it costs to maintain, and how much space it takes. Refrigerated dryers are usually more energy efficient and require less maintenance than desiccant dryers, but in highly critical applications, the extra cost of a desiccant dryer can be worth it in the long run.

By understanding the pros and cons of each type of air dryer, you can make a more informed decision for the specific needs of your compressed air system. And don't forget, keeping your air quality up is about more than just saving energy. It's also an investment in the long-term health of your business.