.png)

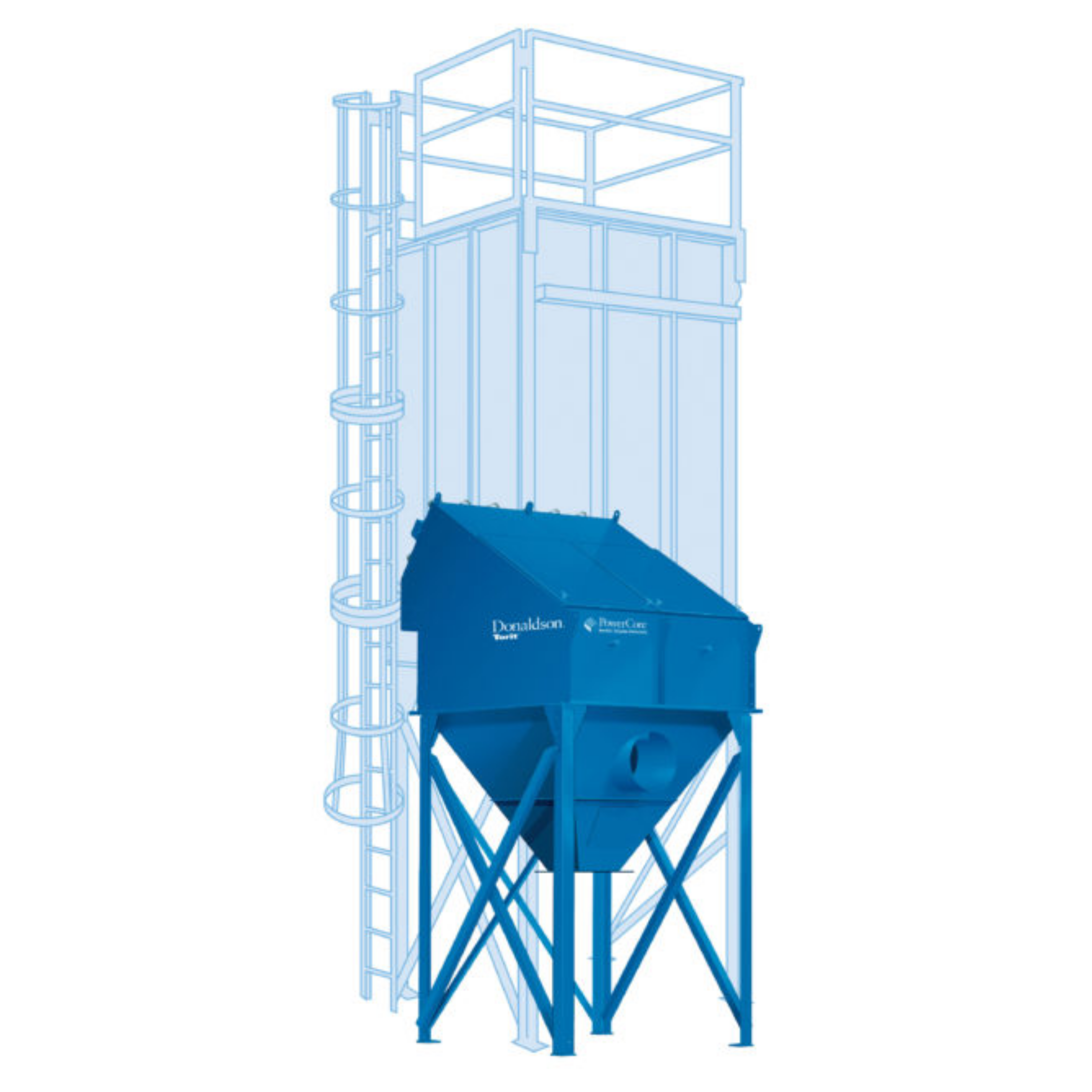

Dust collector is a machine that sucks dust and smoke in a place such as a factory which can cause air pollution in the surrounding environment because of the industrial process.

There are 4 types of dust collectors that are often found in the industrial world:

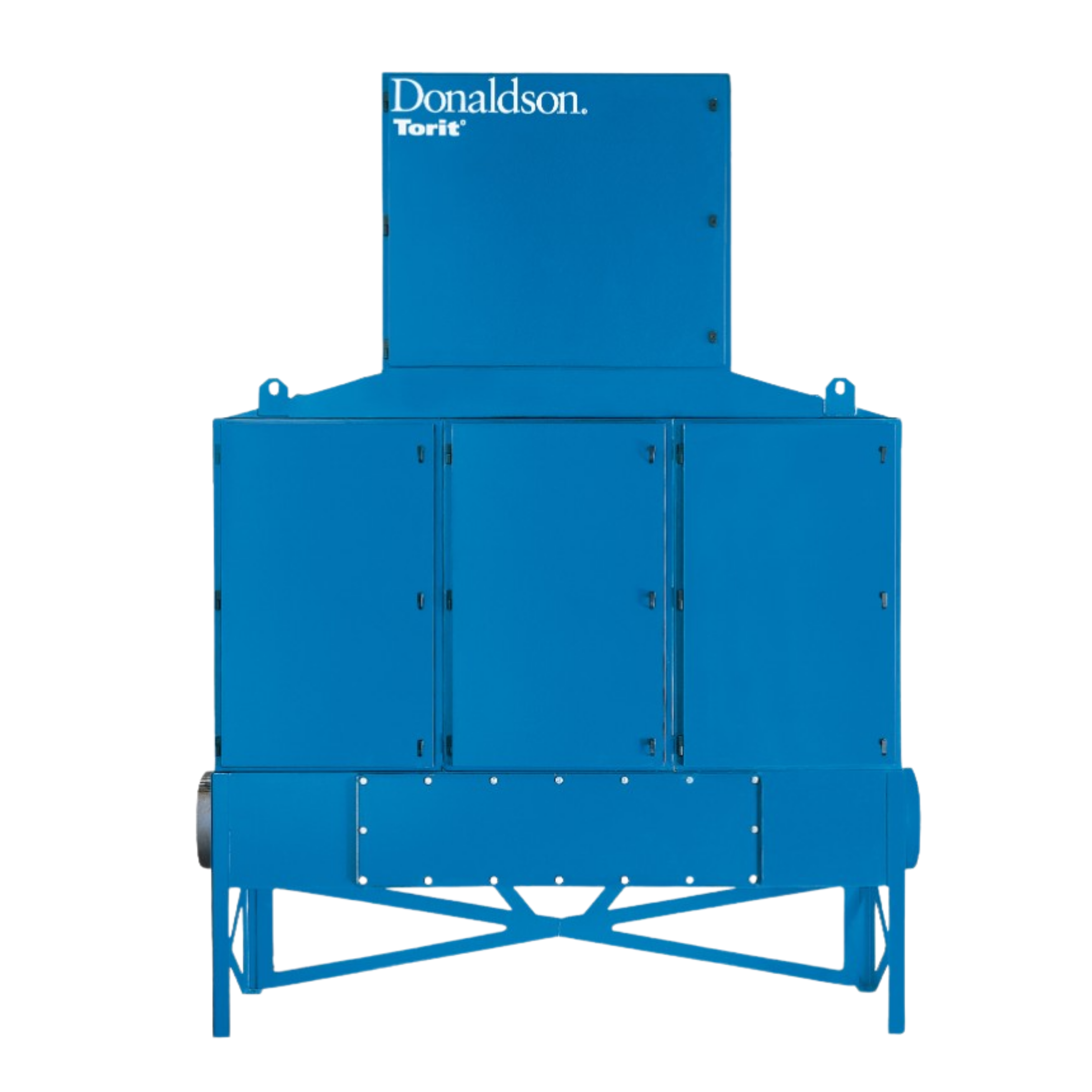

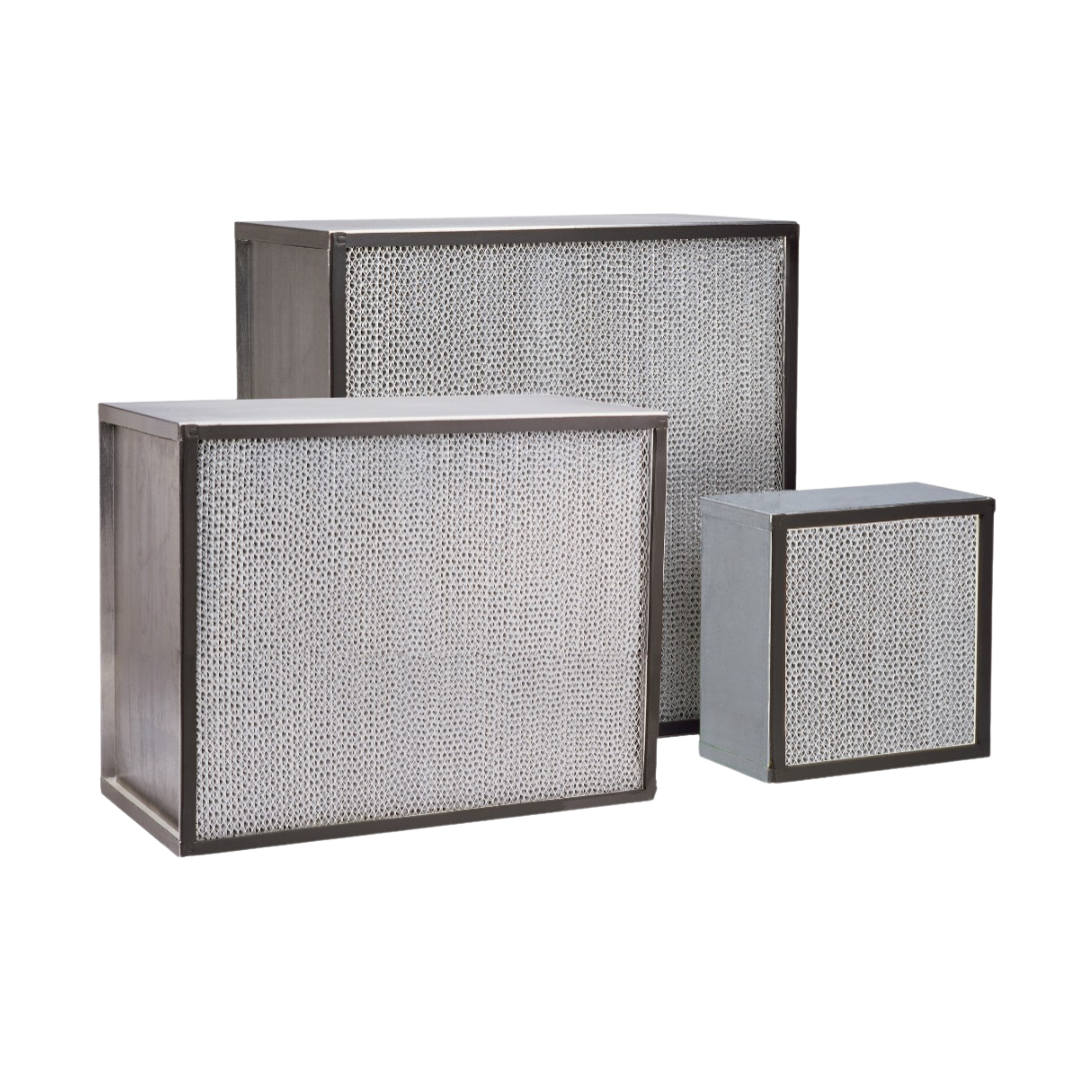

1. Fabric Filter

Fabric Filter is an emission control system using a filter to separate dust from gas. This system is among the most effective of several types of dust collector systems. Fabric filter can filter more than 99% fine dust.

_1656646635.png)

2. Wet Scrubbers

Wet Scrubbers Dust Collector is a particulate collector or pollution control device that uses very fine liquid droplets on a liquid to wash unwanted pollutants from a gas stream. Most fine particles will adhere to liquid droplets when they come into contact. Principle of scrubbers is to use the inertial forces of particulates and droplets to transfer particulates from the gas stream to the liquid, particulates in the air stream are forced to come into contact with liquid droplets, liquid packing material, liquid jets from the plate.

3. Electrostatic precipitators.

Electrostatic precipitator (electrostatic precipitate coating) uses electrostatic force to separate dust particles from exhaust gases. Gas contaminated with impurities will flow through a kind of path formed by the output current and the collecting electrode. The electrostatic precipitator is operated according to the same principles that apply to home “ionic” air purifiers.

The collected material on the electrodes will be removed by gently tapping or vibrating the collecting electrode continuously or at a certain time. Precipitator cleaning can be carried out without disturbing the air flow rate.

The four main components of all electrostatic precipitators include:

a. Power supply unit, to produce high DC voltage.

b. Ionizing section, to charge the particles in the air stream.

c. A number of tools to remove collected particles.

d. Container to cover the precipitator zone.

4. Unit collectors.

The collector unit is a type of dust collector that controls contamination directly at the source. The shape of this tool is small and compact, consisting of a fan and several dust collector components. This tool can be operated in various placement conditions, such as permanently in one place, moving around, or being moved periodically. The advantages of the collector unit are that it does not require a large space in placement and is economical in initial costs.

Those are the types of dust collectors that are often found in the industrial world. So, make sure you use the right dust collector for the industry, yes!

.png)

.png)

.png)

.png)

.png)

.png)