In industrial settings, dust is often taken for granted as a problem, even though its impact can be huge—on the health of workers and the smooth operation of the industry. Many people don't realize that the dust they breathe in every day can cause serious health problems, and also machines that are constantly exposed to dust are also at high risk of damage. That's why dust collectors are so important. In this article, we'll talk about why dust collectors are so important and can’t be underestimated in the industry.

Keeping Workers Healthy in an Industrial Environment

Hey, have you ever felt short of breath or irritated when you were in a factory? Dust flying around in an industrial environment is not only annoying, but it can also be bad for your health. Dust collectors are the main solution for dealing with this. They suck dust and harmful particles out of the air to keep the air quality where it should be. This tool makes sure the air is clean and safe for workers to breathe.

If you don't have a proper dust control system, your workers could get really sick. They could get things like asthma, chronic bronchitis, and lung cancer. In the wood processing industry, for example, fine, lightweight sawdust can fly around and get into your lungs. The same is true in textile factories, where tiny fibers from fabrics can get stuck in your respiratory tract. With a dust collector, you can cut down on these health risks and make the workplace healthier and more comfortable for all your workers.

Protecting Production Machinery from Damage

Dust isn't just an issue for workers, it's also a problem for production machinery. Little particles that settle on machines can get into the nooks and crannies of components, build up, and eventually cause wear and tear. In the long run, if dust isn't managed well, it can lead to more frequent repairs and even shorten the lifespan of your machines.

For example, in the metal industry, dust particles from welding or metal cutting processes can stick to the electrical system of the machine, causing short circuits or damage. The same is true in food factories, where flour dust that builds up in processing machines can reduce equipment performance and mess with product quality. With a dust collector, all these dust particles can be sucked up before they cause any problems. This keeps the machine cleaner and more efficient, and production downtime is minimized.

On top of that, clean air helps keep the engine temperature stable. Machines exposed to dust usually heat up faster, which increases the risk of overheating. With a dust collector, you can get rid of dust that hinders air circulation, ensuring that the engine works optimally in the long run.

Various Types of Dust Collector for Various Needs

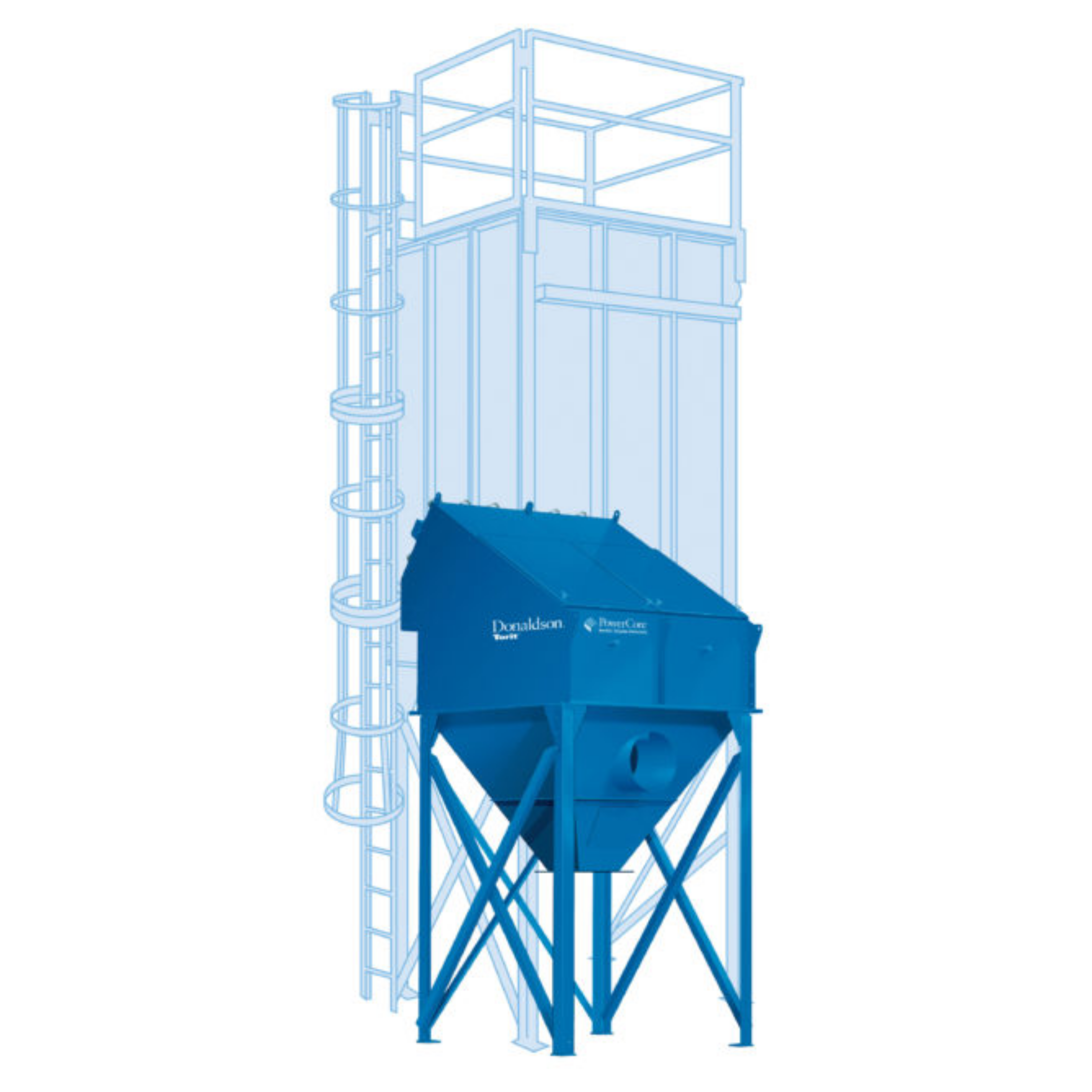

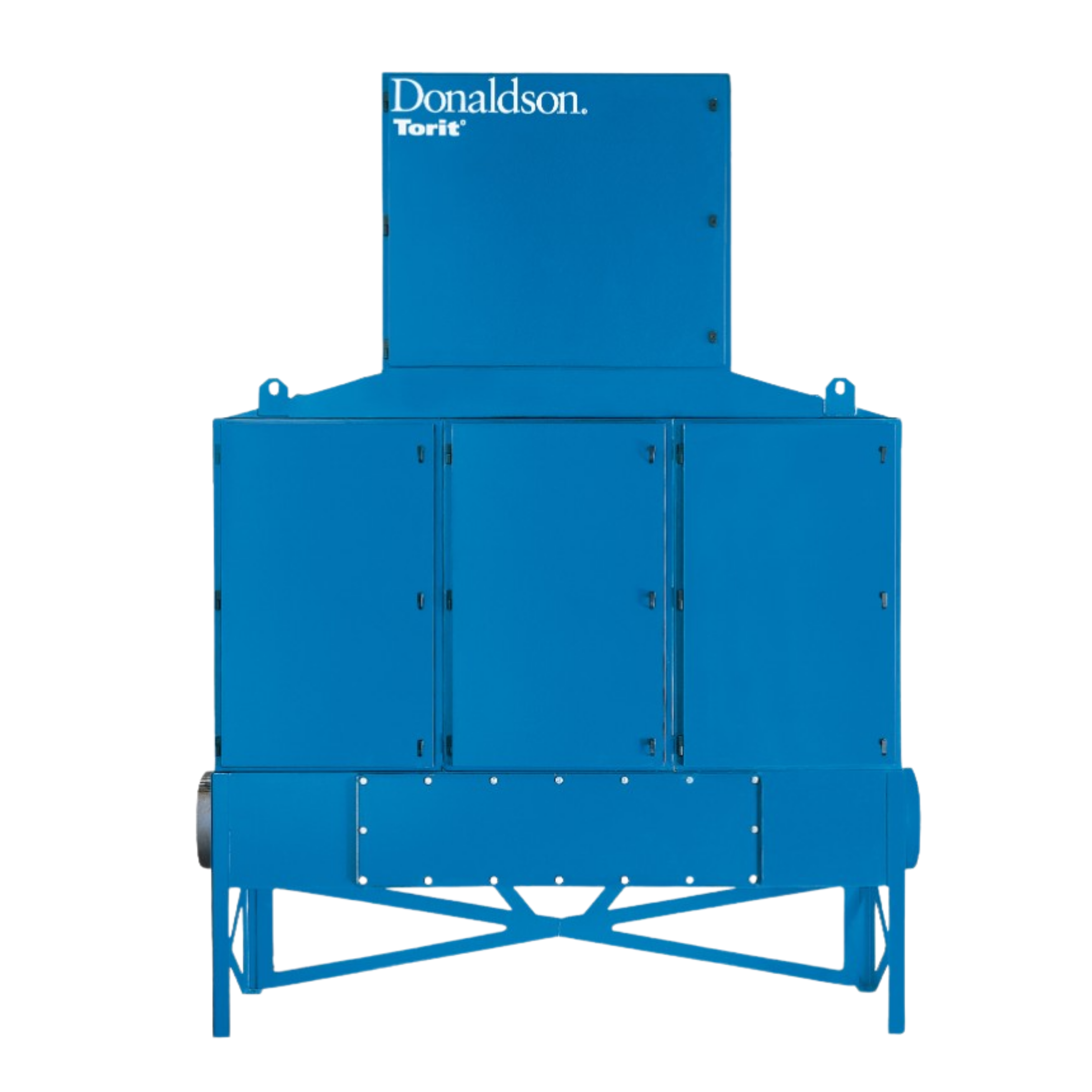

Every industry has its own unique challenges when it comes to dealing with dust, so it's important to choose the right dust collector for your specific needs. Baghouse dust collectors are a popular choice, especially in the cement processing industry and plastic plants. They use filter bags to capture a lot of fine dust, making them great for large-scale production.

For industries that process wood or metal, a cyclone dust collector is often the go-to choice. It uses centrifugal force to separate coarse dust particles from the airflow. This type is great for handling wood chips, metal, or other coarse materials. But in the pharmaceutical and electronics sectors, where dust is very fine, cartridge dust collectors are the best solution. They capture fine particles with great precision, keeping products clean and of high quality.

For example, in pharmaceutical factories, it can be really hard to deal with small particles of drug powder using regular tools. Cartridge dust collectors with high-tech filters can solve this problem, keeping the work environment safe and sterile. There are so many different types of dust collectors out there, so it's important to understand the specific needs of each industry so that the chosen tool delivers optimal results.

Innovative Technology of Dust Collector

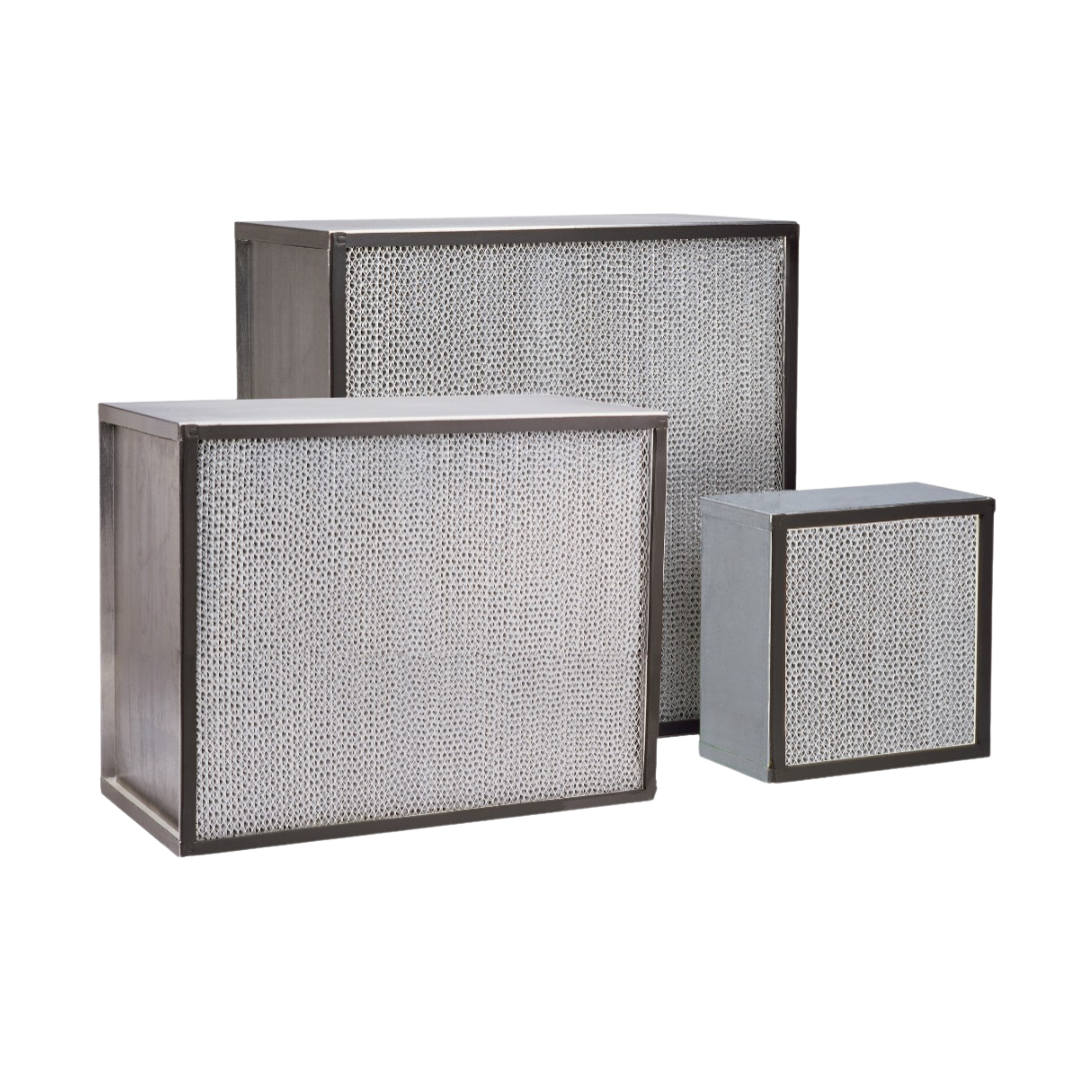

Dust collectors have really improved in terms of efficiency and ease of use thanks to technological advances. These days, a lot of tools have sensor-based automatic cleaning systems. These sensors can detect the level of dust accumulation on the filter and automatically clean it when the filter is full. This is especially helpful for industries that operate 24/7, such as food factories or automobile manufacturing.

Nanotechnology filters are becoming a common sight in dust collectors. These filters can catch particles that usually get past regular filters. This tech is great for industries that need to keep things super clean, like food, pharmaceuticals, and technology. Some dust collectors even have the Internet of Things (IoT), which lets you check on them from your phone. This feature lets technicians keep an eye on tool performance in real-time, spot problems early, and manage tool operation without being on site.

Some dust collector manufacturers also offer modular designs, which let companies increase the capacity of the equipment as needed without replacing the whole system. This is especially useful for businesses that are growing fast and need to be able to make changes quickly. With all these innovations, dust collectors are no longer just air purifiers, but smart solutions that can improve efficiency and safety in the workplace.

With Clean Air, Productivity Improves

If you work in an industrial setting, don't underestimate the importance of a dust collector. This tool is crucial for both worker health and production efficiency, as well as keeping the company running smoothly. Having clean air creates a more comfortable work environment, increases productivity, and reduces the risk of health problems for both machines and workers.

Investing in a dust collector is a smart move for your business. It'll save you money in the long run and keep your business running smoothly. Plus, it'll protect your company's most important assets: your workers and production equipment. So don't wait until dust problems become a major disaster in your workplace.

.png)

.png)

.png)

.png)

.png)

.png)