.jpg)

In today's industrial world, a reliable dust collector is not just a nice-to-have, it's a must. If you're in charge of a woodworking shop, a mining facility, or a chemical plant, airborne dust and particles can really affect safety and productivity. This article will look at the important role dust collectors play in industrial environments, focusing on how they contribute to employee well-being, operational efficiency, product quality, and environmental compliance.

Employee Health and Safety Should Be a Top Priority

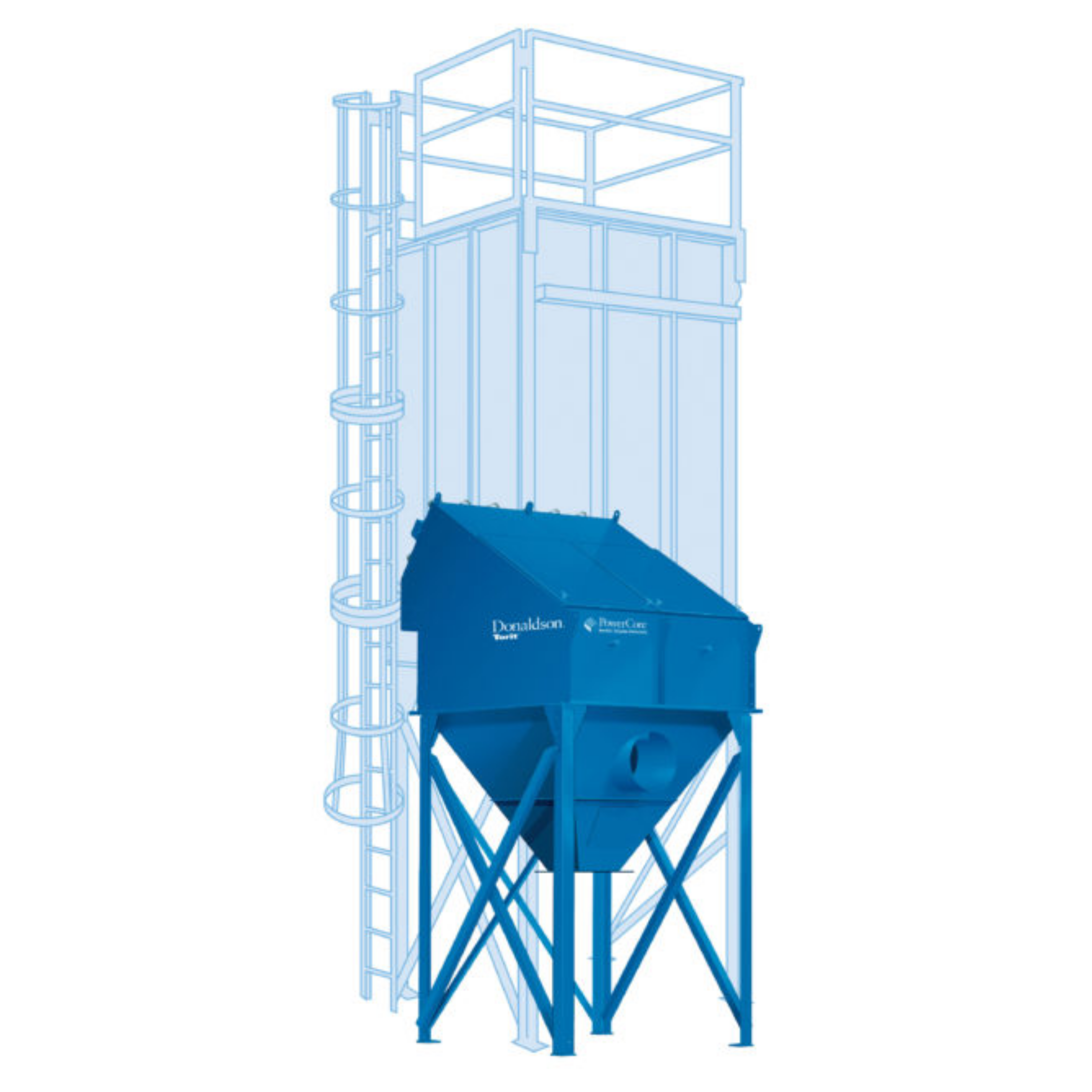

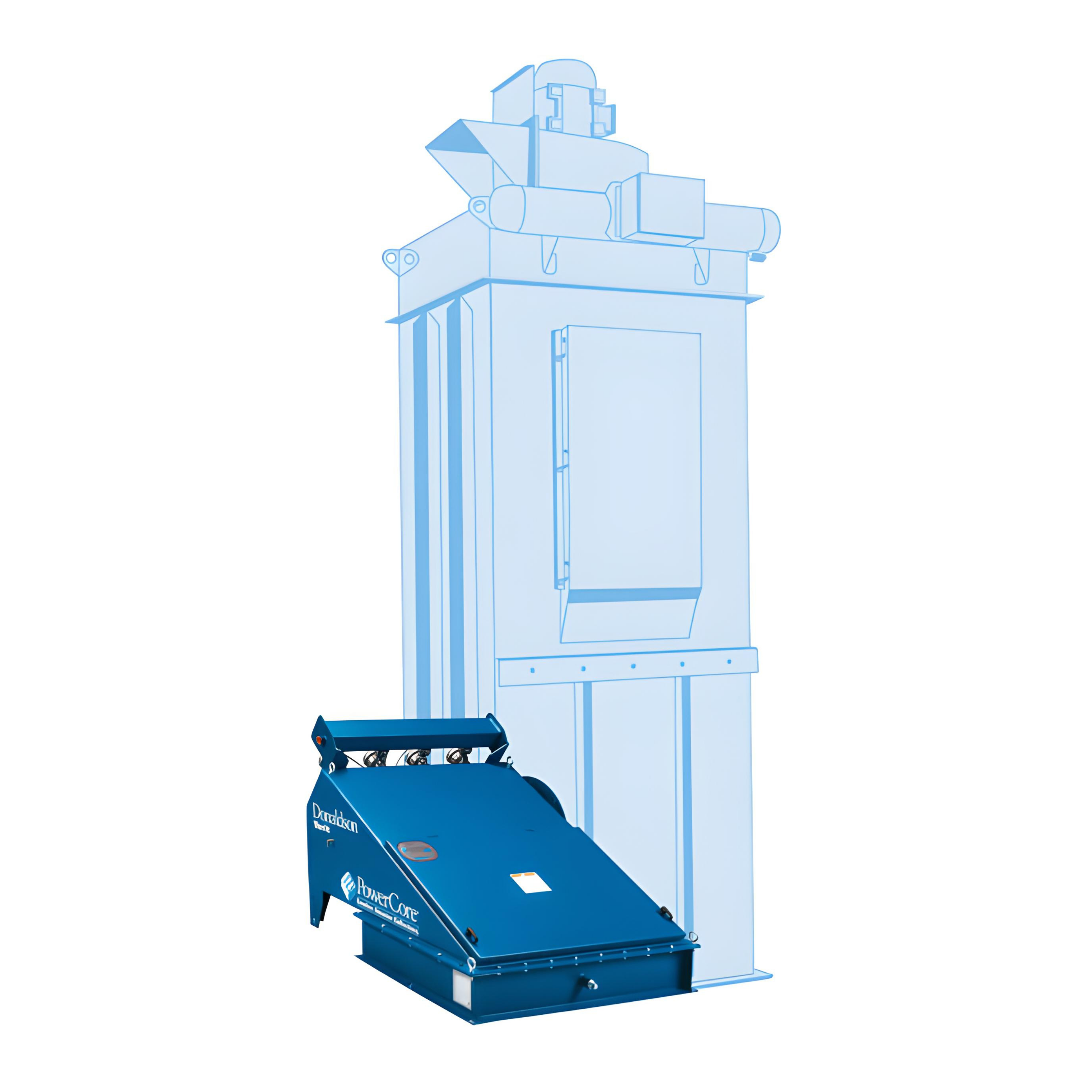

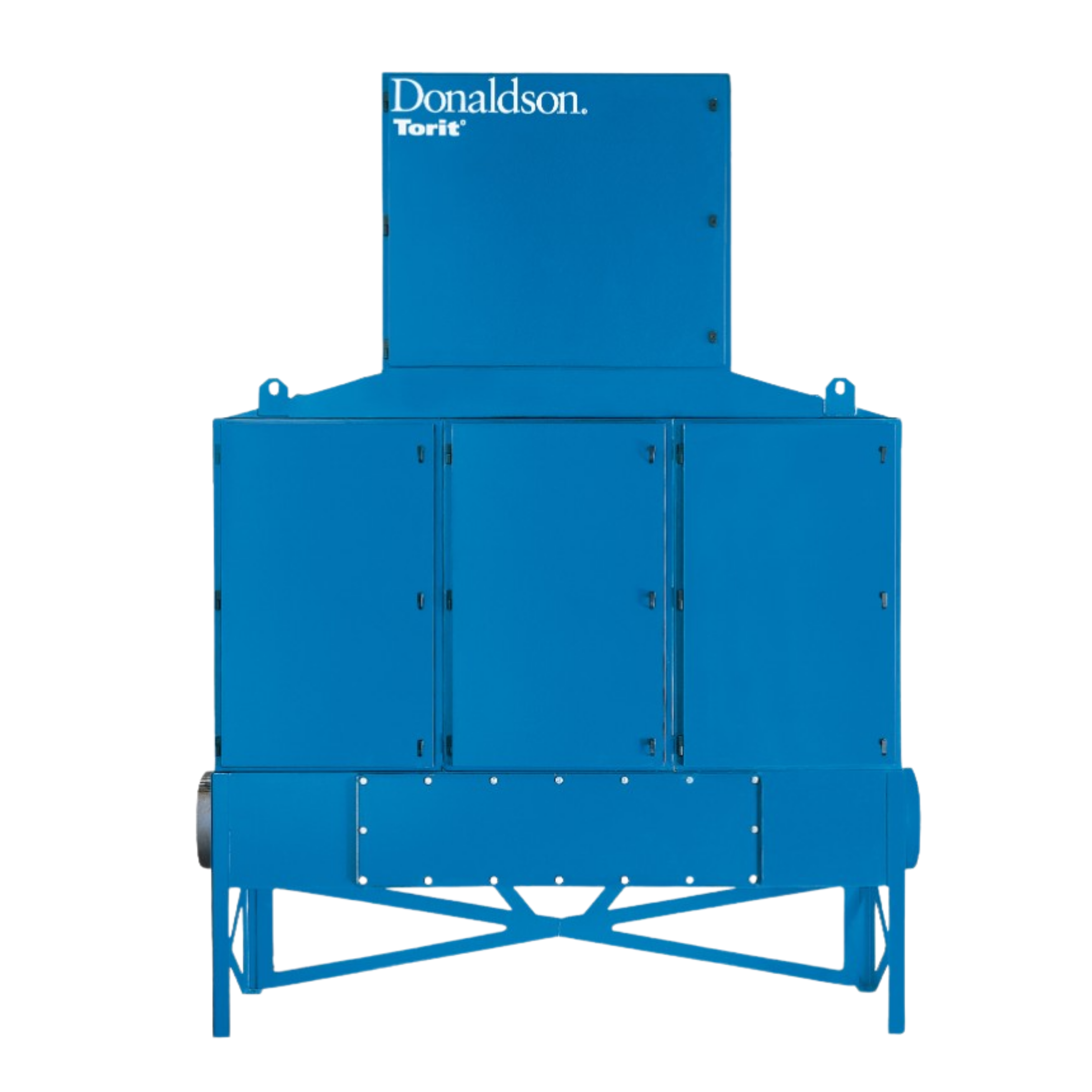

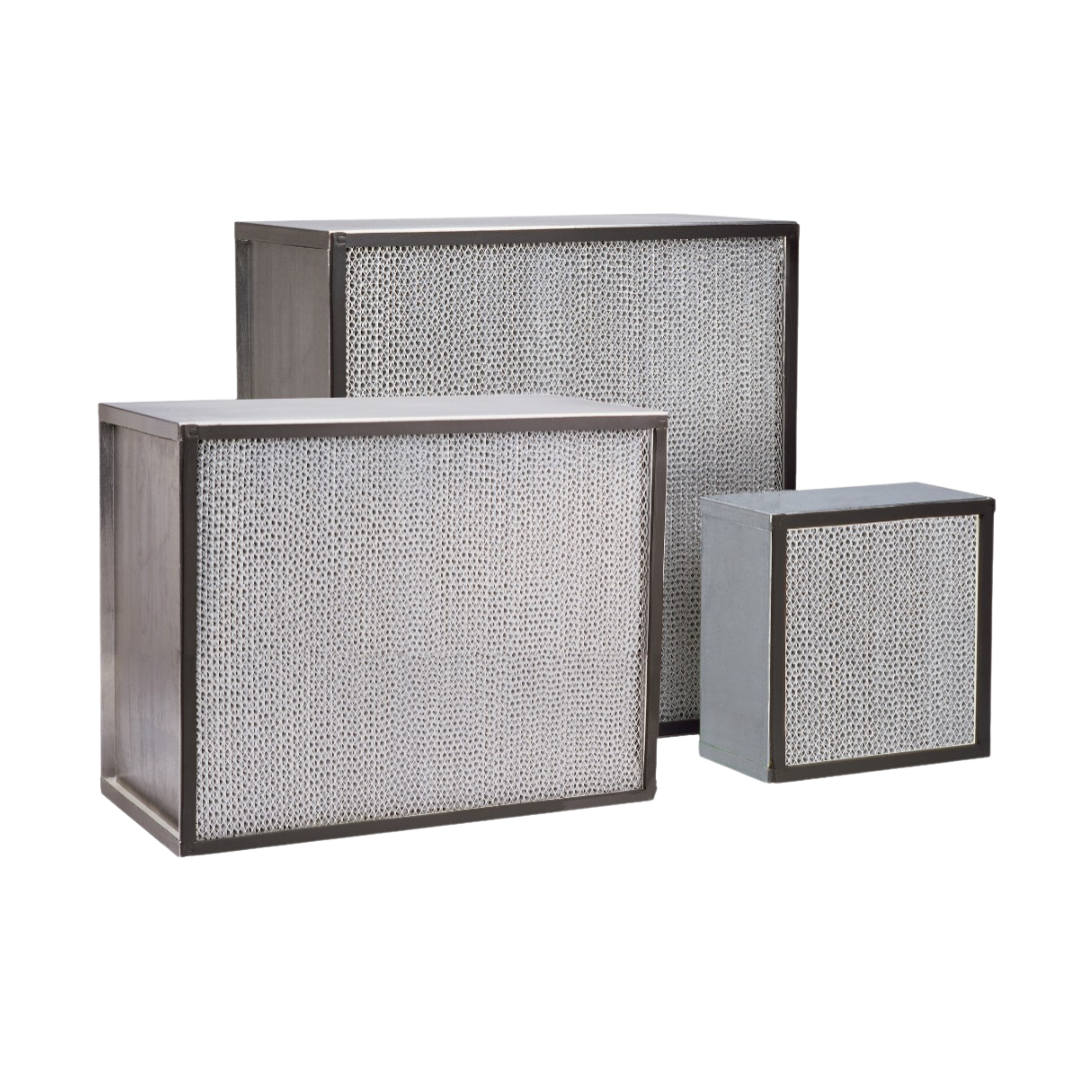

Airborne dust is a big problem in many industries. Mining, metalworking, and pharmaceuticals create risky small particles that can be breathed in. Contact with dust can cause breathing problems or long-term health issues. In the mining industry, top-notch cyclone dust collectors capture up to 95% of particles. For smaller particles, use a baghouse system with a filter bag dust collector. This setup thoroughly filters the air.

Dust can be dangerous in more ways than one. It can pose a health risk and also cause fires. If dust from things like wood, metal or chemicals isn't handled properly, it can catch fire and cause an explosion. This is why manufacturers of industrial dust collectors say it's important to have advanced systems in place, especially in facilities that deal with combustible dust. A well-planned dust collection system isn't just about preventing fires, but also about keeping workers safe and avoiding the costs of accidents.

Good Dust Collector Can Boosts Operational Efficiency

Dust can affect air quality and operational efficiency. For example, dust on tools can block sensors and cause machinery to malfunction. Over time, this can lead to machines operating less effectively, which can result in frequent malfunctions, expensive maintenance, and sometimes unexpected closures that can disrupt production for extended periods.

By putting in a custom-made dust collector that's just right for your needs, you can cut down a lot on the work you have to do to keep your equipment in good shape. For instance, a mining dust collector is made to handle a lot of dust, so it stops it from building up on your equipment and keeps everything running smoothly. When you don't have to spend as much time and money on maintenance, you can get more done, which is good for your business and your budget.

Improving Product Quality with Clean Air

Dust isn't just an annoying distraction; it can also affect the quality of your products, particularly in industries like food, electronics, pharmaceuticals, and textiles. Even a tiny amount of dust in the air can cause product defects, contamination, or recalls. Dust landing on food or medicine can put their safety at risk, and in electronics manufacturing, dust can lead to problems with circuits and components. A quality dust collection system captures small particles before they cause issues, so your products stay clean and compliant with required standards.

Keeping the air clean is key to stopping contamination, especially when you're handling chemicals, allergens or other delicate materials. By choosing the right dust collection system for your facility, you're not only avoiding defects but also making sure that each product is consistently high-quality and safe. This cuts down on waste, reduces downtime and enhances your brand's image, ensuring satisfied and loyal customers.

Staying Compliant with Environmental Regulations

Manufacturing plants are under pressure to stick to the rules set by agencies like the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA). Meeting air quality rules isn't just about avoiding penalties. It's also about showing you care about your workers and the local area. Baghouse systems, like dust collectors, can be as efficient as 99% for larger particles. This helps facilities meet or even exceed the rules.

If you don't stick to these rules, you could end up with some hefty fines or even have your business shut down. Take Cemex, Inc., a big cement producer, for example. They got hit with a $1.4 million fine in 2011 for breaking emission regulations. Investing in a top-notch dust collection system is a great way to reduce these risks and show you're taking a proactive stance on environmental responsibility.

How to Pick the Right Dust Collector for Your Facility

Choosing the right dust collector means understanding what you need it to do. Cyclone dust collectors are perfect for handling heavier, larger particles, which makes them well-suited for use in woodworking shops and mining facilities, for instance. If your facility creates smaller particles, like in the pharmaceutical or chemical industry, a dust collector with filter bags will be more efficient. These systems come with filters that are designed to trap tiny particles, so the air you release is clean.

It's also worth thinking about the materials you're dealing with. For instance, aluminium, which is used in metalworking factories, can create dangerous dust that's flammable. Wet dust collectors are a good option here as they use water to get rid of and trap dust particles, reducing the chance of fires. Mining dust collectors might need to be more durable to effectively manage high volumes of abrasive materials, ensuring a long lifespan and reliable performance.

Financial Conditions When Buying a Good Dust Collector

Purchasing a dust collection system is a great way to keep your workplace safe and clean, and it's also a smart financial move. Clean air helps your equipment last longer by reducing dust build-up and preventing malfunctions. You'll save money on repairs and avoid costly downtime when your machines operate efficiently. Over time, these advantages add up, helping you keep costs down and production high. Studies show that a quality dust control system can boost productivity by up to 15%, leading to higher output and more profits for your company.

On top of that, fresh air helps keep your items in good shape, which means less waste and fewer recalls or reworks caused by contamination. By keeping things running smoothly and consistently, you can stay on track with your operations and meet your customers' expectations. So, even though a dust collector might seem like a big expense upfront, it's actually a long-term investment that boosts productivity, protects your machinery, and brings in more money.

.png)

.png)

.png)

.png)

.png)

.png)